Furnace bottom ramming material of RH refining furnace

A technology of ramming material and refining furnace, which is applied in the field of refractory materials for the bottom of RH refining furnace, can solve the problems of environmental pollution and human harm, and achieve the effects of excellent high temperature performance, promotion of sintering, and improvement of thermal shock stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

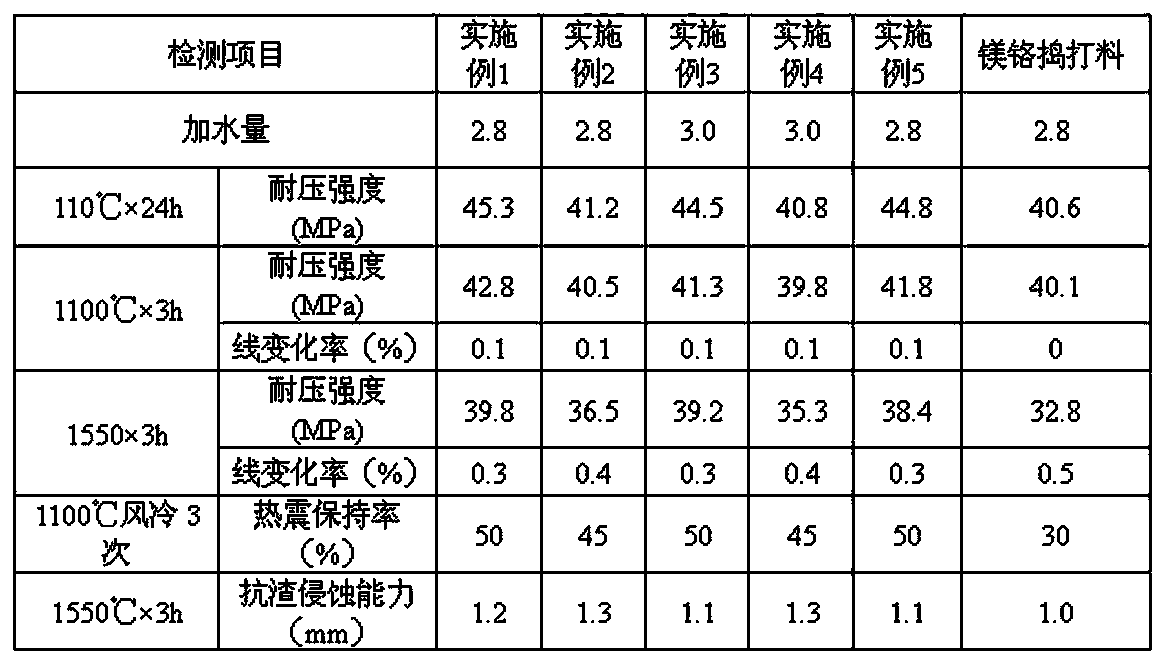

Examples

Embodiment 1

[0035] A RH refining furnace bottom ramming material, the weight percentage of each component in the raw material is: take 30% of large crystal fused magnesia with a particle size of 3~5mm, and 20% of large crystal fused magnesia with a particle size of 1~3mm %, 15% of large crystal fused magnesia with a particle size of 0~1mm, 15% of large crystal fused magnesia with a particle size of 200 mesh, 8% of magnesia-aluminum spinel with a particle size of 320 mesh, Al 2 o 3 Micropowder 3%, metal aluminum powder 7%, metal silicon powder 2%, and the mass of magnesium chloride as a binder is about 3% of the dry material mass. The above raw materials are mixed according to the ratio and mixed evenly in the forced mixer to make dry powder materials. When using, add appropriate amount of water and stir evenly.

Embodiment 2

[0037] A RH refining furnace bottom ramming material, the weight percentage of each component in the raw material is: take 33% of large crystal fused magnesia with a particle size of 3~5mm, and 22% of large crystal fused magnesia with a particle size of 1~3mm %, 10% of large crystal fused magnesia with a particle size of 0~1mm, 15% of large crystalline fused magnesia with a particle size of 200 mesh, 10% of magnesium aluminum spinel with a particle size of 320 mesh, active α-Al 2 o 3 4% micro powder, 4% metal magnesium powder, 2% metal silicon powder, plus 3% binder sodium silicate. The above raw materials are mixed according to the ratio and mixed evenly in the forced mixer to make dry powder materials. When using, add appropriate amount of water and stir evenly.

Embodiment 3

[0039] A RH refining furnace bottom ramming material, the weight percentage of each component in the raw material is: take 35% of large crystal fused magnesia with a particle size of 3~5mm, and 15% of large crystal fused magnesia with a particle size of 1~3mm %, 20% of large crystal fused magnesia with a particle size of 0~1mm, 10% of large crystal fused magnesia with a particle size of 200 mesh, 8% of magnesia-aluminum spinel with a particle size of 320 mesh, Al 2 o 3 Micropowder 4%, metal aluminum powder 6%, metal silicon powder 2%, and the quality of the binder sodium hexametaphosphate is 4% of the dry material. The above raw materials are mixed according to the ratio and mixed evenly in the forced mixer to make dry powder materials. When using, add appropriate amount of water and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com