Nano dolomite-containing corundum spinel castable

A technology of corundum spinel and nano-dolomite, which is applied in the field of inorganic non-metallic materials, can solve the problems of high cost and achieve the effects of low price, easy source and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

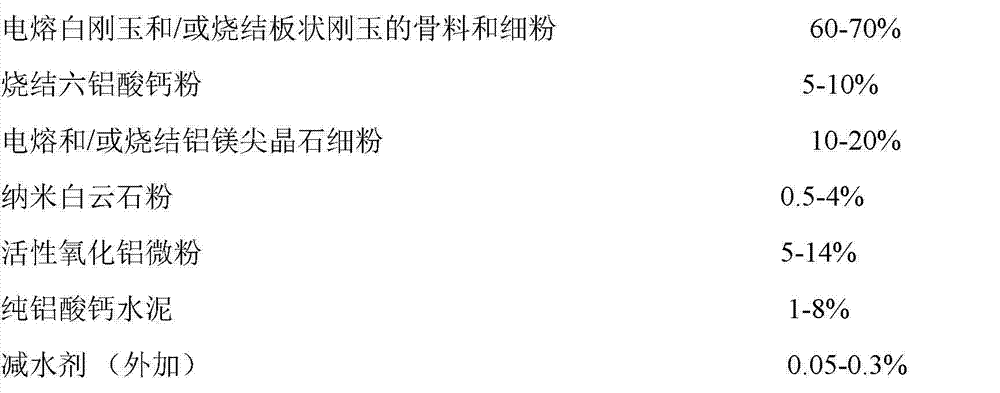

Method used

Image

Examples

Embodiment 1

[0018] Example 1: The proportion of each component is (mass percentage) fused white corundum particles 63.0%, sintered calcium hexaaluminate powder 5%, fused aluminum magnesium spinel fine powder 10.0%, nano dolomite powder 4.0% , activated alumina micropowder 10.0%, pure calcium aluminate 8.0%, superplasticizer 0.3% (additional).

Embodiment 2

[0020] Example 2: The proportion of each component is (mass percentage): 67.0% of sintered tabular corundum particles, 5% of sintered calcium hexaaluminate powder, 15.0% of sintered aluminum-magnesium spinel fine powder, and 2.0% of nano-dolomite powder, Activated alumina powder 7.0%, pure calcium aluminate cement 4%, superplasticizer 0.2% (additional).

Embodiment 3

[0022] Example 3: The proportion of each component is (mass percentage): 70.0% of sintered tabular corundum particles, 10% of sintered calcium hexaaluminate powder, 10.0% of sintered aluminum-magnesium spinel fine powder, and 1.0% of nano-dolomite powder, Activated alumina micropowder 8.0%, pure calcium aluminate cement 1.0%, superplasticizer 0.1% (additional).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com