Novel circulating water cooling tower return water pressure adjusting system

A pressure regulation, cooling tower technology, applied in the direction of water shower cooler, heat exchanger type, heat exchange equipment, etc., can solve problems such as filter plate clogging, and achieve the effect of easy replacement, convenient adjustment, and prevention of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

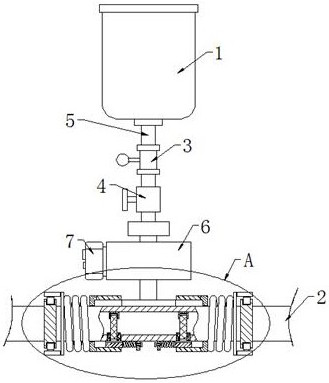

[0026] Example 1 as figure 1 As shown, this new circulating water cooling tower return water pressure adjustment system includes a cooling tower 1, a water inlet pipe 2, a flow sensor 3 and a throttle valve 4, and the flow sensor 3 and the throttle valve 4 are set to adjust the return water pressure , the top of the water inlet pipe 2 is provided with a diversion pipe 5, the top of the diversion pipe 5 is fixedly connected to the bottom of the cooling tower 1, the flow sensor 3 and the throttle valve 4 are fixedly connected to the upper end of the pipe wall of the diversion pipe 5, and the flow diversion A water storage tank 6 is socketed under the pipe wall of the pipe 5, a booster water pump 7 is fixed on the left side of the water storage tank 6, and a filter plate 8 is provided on both sides of the pipe wall of the water inlet pipe 2, and a filter screen 8 is provided for circulating water. Filter to prevent impurities from blocking the pipeline. The bottom of the pipe wal...

Embodiment 2

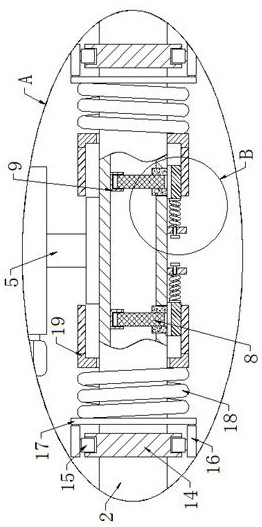

[0027] Embodiment 2 is on the basis of embodiment 1 such as figure 2 As shown, the upper ends of both sides of the pipe wall of its water inlet pipe 2 are provided with arc-shaped blocks 9, and the bottom of the arc-shaped blocks 9 is provided with an arc-shaped groove, and the top of the filter plate 8 is in contact with the groove wall of the arc-shaped groove. The arc-shaped block 9 and the arc-shaped groove carry out limit installation to the filter plate 8 .

Embodiment 3

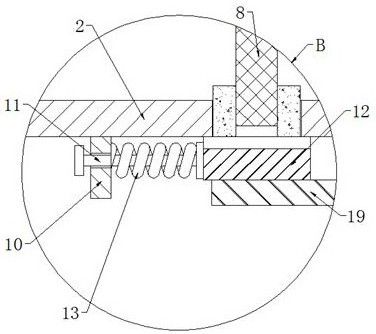

[0028] Embodiment 3 is such as on the basis of embodiment 1 image 3 As shown, its connection mechanism includes two symmetrically arranged fixed plates 10, the fixed plate 10 is fixedly connected with the bottom of the water inlet pipe 2, and both of them are slidingly sleeved with a T-shaped bar 11, and one end of the bar wall of the T-shaped bar 11 is fixedly arranged. There is an arc-shaped plate 12, the arc-shaped plate 12 is located below the arc-shaped installation groove, and is in contact with the outside of the pipe wall of the water inlet pipe 2. The bar wall of the T-shaped bar 11 is sleeved with a first spring 13, and the first spring 13 The two ends are fixedly connected with the arc plate 12 and the fixed plate 10 respectively, and the bottom of the arc plate 12 is provided with threads, and the arc plate 12 is set to connect and seal the filter plate 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com