Recycled concrete with high slump retaining performance and preparation method thereof

A recycled concrete, performance technology, applied in the field of concrete, can solve the problems of poor workability of recycled concrete, loss of concrete slump, rough surface of recycled aggregate, etc., to achieve the effect of reducing agglomeration, slump protection, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

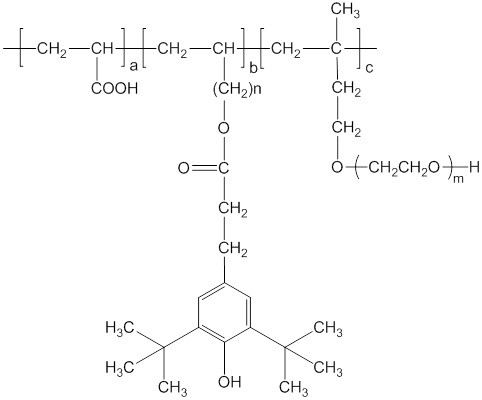

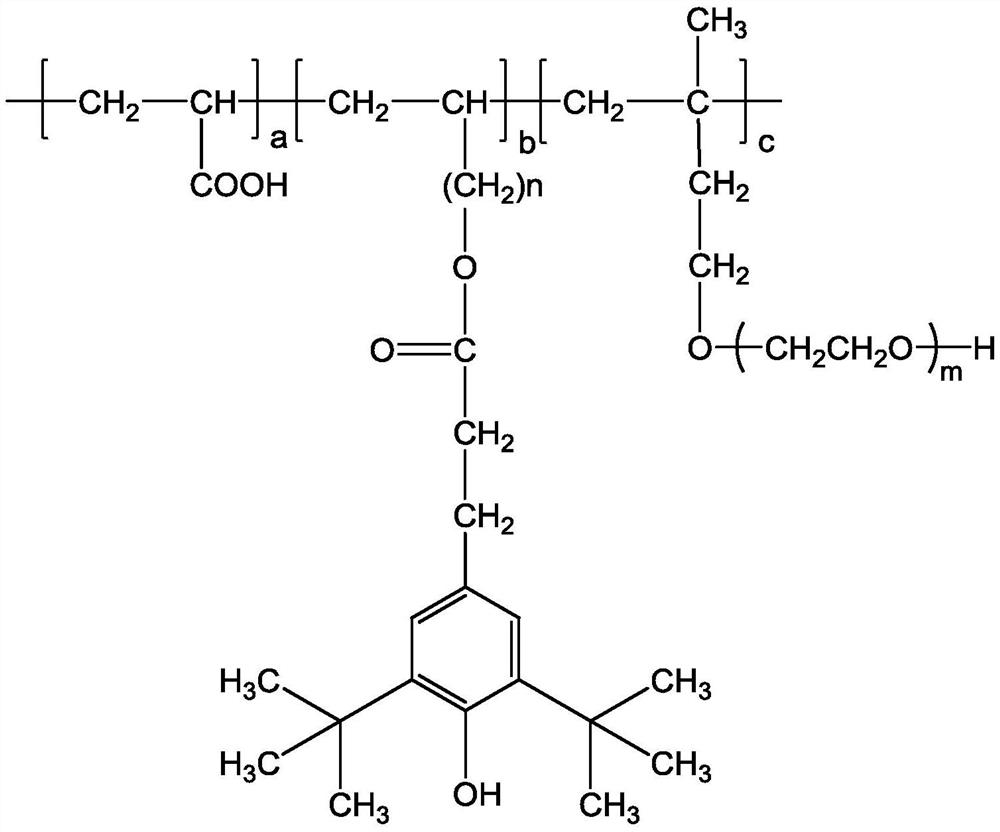

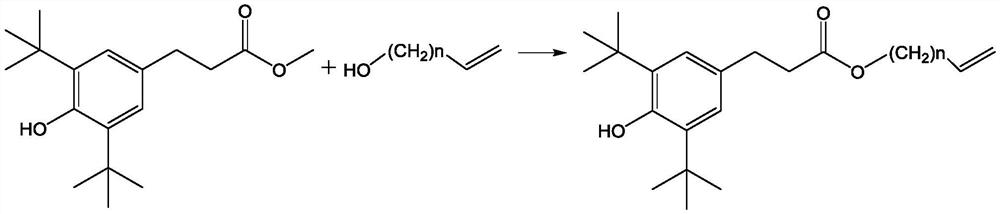

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Raw materials: 400kg of cement, 450kg of sand, 650kg of natural aggregate, 200kg of recycled aggregate, 80kg of fly ash, 50kg of mineral powder, 150kg of water, and 2kg of slump-preserving polycarboxylate superplasticizer A.

[0053] The preparation process is:

[0054] (1) Stir and mix cement, sand, natural aggregate, recycled aggregate, fly ash, and mineral powder evenly to obtain dry material;

[0055] (2) Add the slump-retaining polycarboxylate superplasticizer into water, mix evenly, add it to the dry material, and stir evenly.

Embodiment 2

[0057] Raw materials: 420kg of cement, 500kg of sand, 690kg of natural aggregate, 230kg of recycled aggregate, 100kg of fly ash, 60kg of mineral powder, 170kg of water, and 3kg of slump-preserving polycarboxylate superplasticizer B.

[0058] The preparation process is:

[0059] (1) Stir and mix cement, sand, natural aggregate, recycled aggregate, fly ash, and mineral powder evenly to obtain dry material;

[0060] (2) Add the slump-retaining polycarboxylate superplasticizer into water, mix evenly, add it to the dry material, and stir evenly.

Embodiment 3

[0062] Raw materials: 500kg of cement, 650kg of sand, 800kg of natural aggregate, 300kg of recycled aggregate, 150kg of fly ash, 100kg of mineral powder, 250kg of water, 6kg of slump-preserving polycarboxylate superplasticizer C.

[0063] The preparation process is:

[0064] (1) Stir and mix cement, sand, natural aggregate, recycled aggregate, fly ash, and mineral powder evenly to obtain dry material;

[0065] (2) Add the slump-retaining polycarboxylate superplasticizer into water, mix evenly, add it to the dry material, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com