Equipment for measuring internal size of steel ladle by using laser range finder and operation method thereof

A technology of a laser range finder and an operation method, applied in the field of steel making, can solve the problems of requiring 4 to 5 people to operate at the same time, high daily maintenance costs, cumbersome measurement equipment, etc., and achieves reduced measurement costs, low purchase costs, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0086] Basic parameters of laser range finder

[0087] device name Shendawei Laser Rangefinder Device model SW—S50 largest unit of measure 50m smallest unit of measure 1mm measurement accuracy ±1.5mm Tilt Angle Measuring Range ±90° Tilt Angle Measurement Error ±1.5° Laser wavelength 635nm

[0088] Can accurately measure the distance from the measuring point to the target.

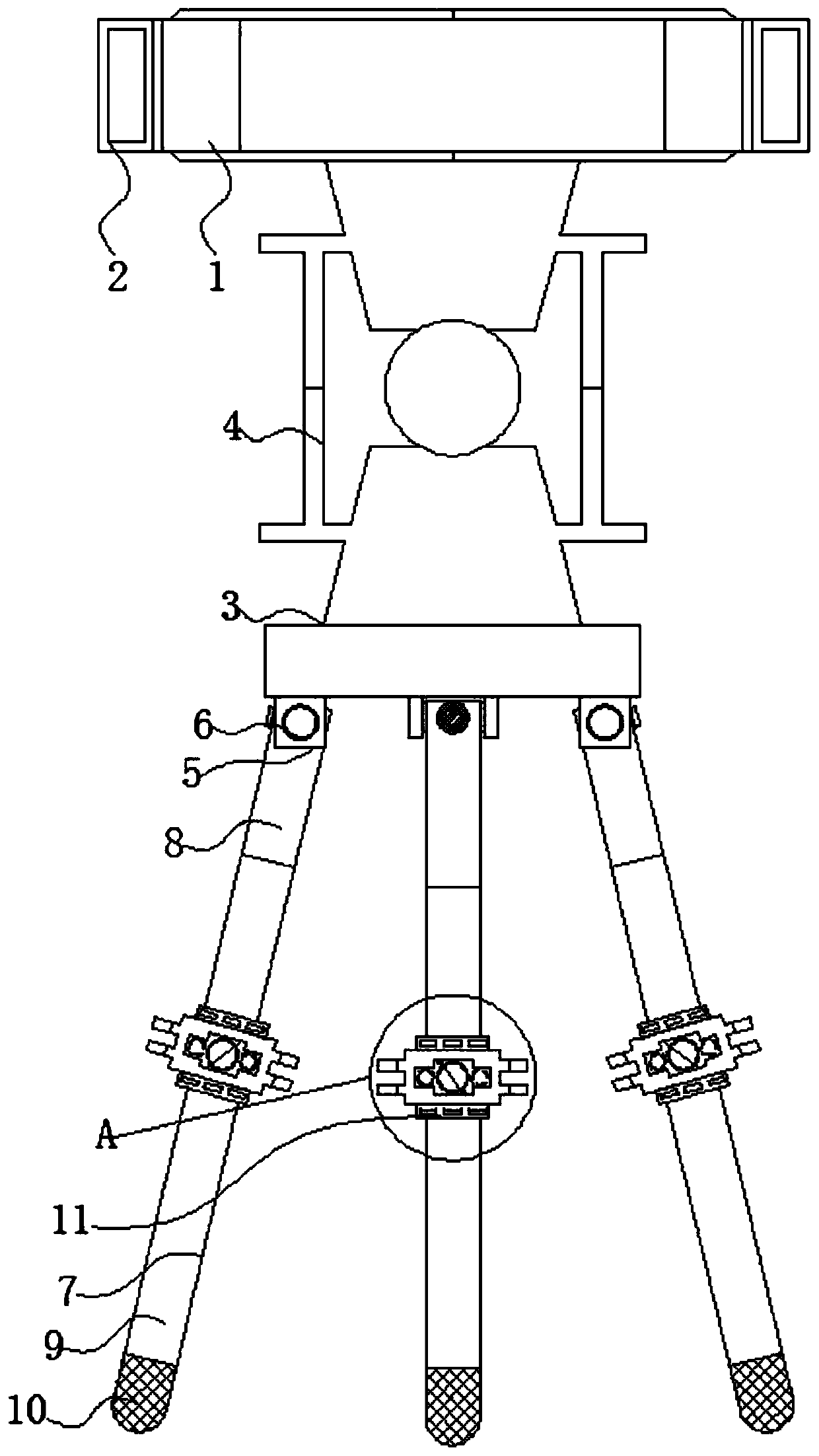

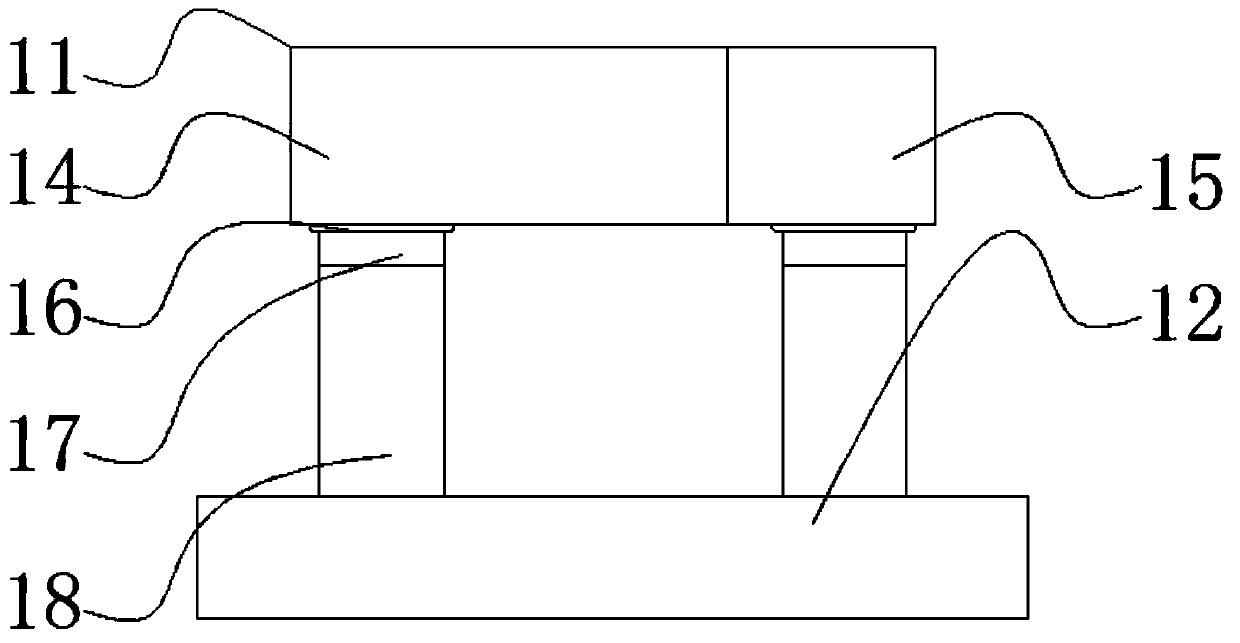

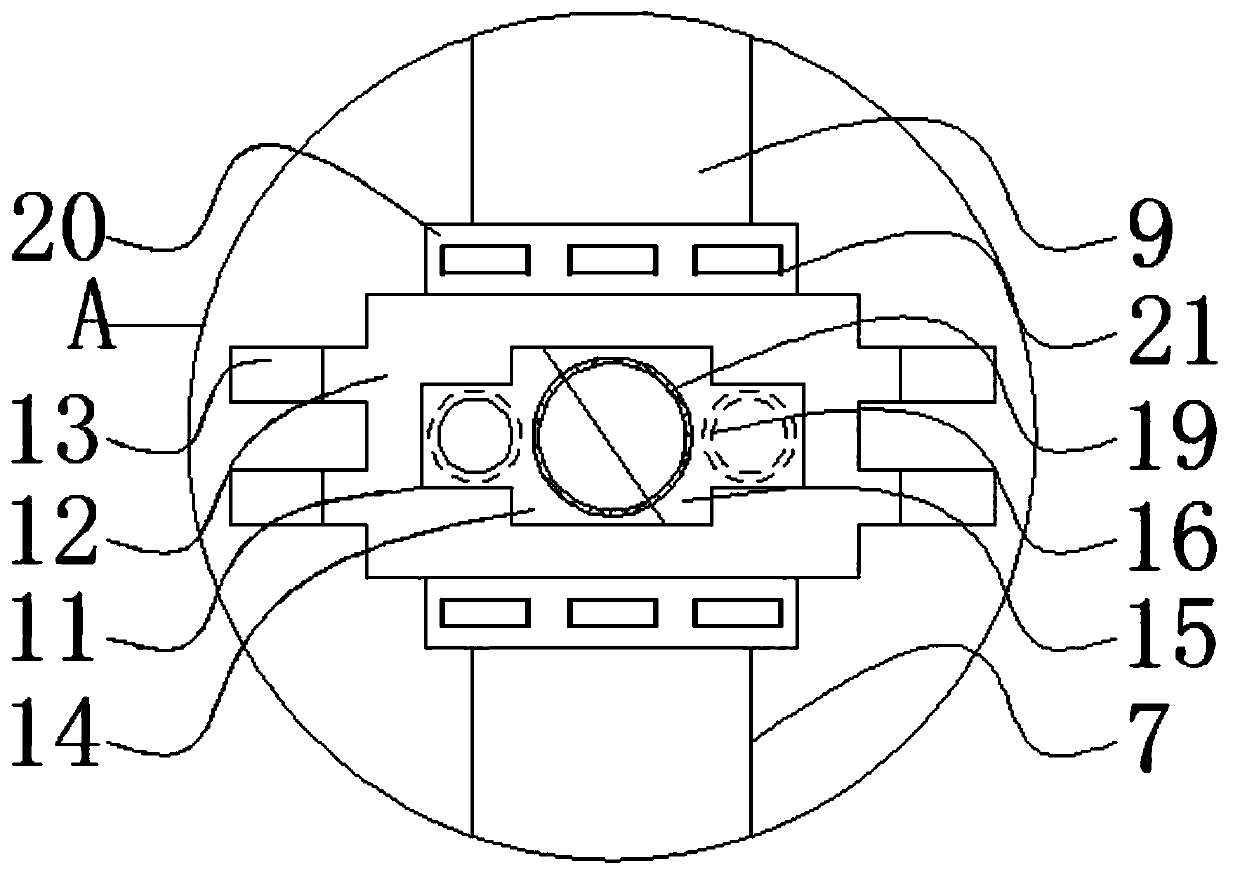

[0089] Basic parameters of tripod

[0090]

[0091]

[0092] Due to the poor stability of the handheld measurement, the measurement center point cannot be saved for continuous measurement at this position, so a tripod is used instead of the handheld measurement. The tripod measurement has high stability, and the center point of the positioning measurement is always saved at this position, and there is no deviation.

[0093] 2D pan / tilt protractor

[0094] device name Kaiweisi double panoramic clip professional two-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com