Technology of preparing rhizoma coptidis micro powder through superfine grinding method

A technology of ultra-fine pulverization and coptis chinensis, which is used in powder transportation, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of complex operation procedures, poor safety and high cost, and achieve simple operation procedures, energy saving, no The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The process of preparing Coptis rhizome micropowder by ultrafine pulverization method, the method adopts low-temperature dry method ultrafine pulverization method to prepare, specifically comprises the following steps:

[0053] (1) Raw material processing: grade the qualified Coptis chinensis medicinal materials, wash and dry, put the dried Coptis chinensis raw materials into a slicer for slicing, with a thickness of 1.5mm;

[0054] (2) Grinding: In the D-level clean area, the Coptis chinensis flakes processed in step (1) are crushed in an ordinary multi-functional grinder, and passed through a No. 2 sieve to obtain coarse powder.

[0055] (3) Sieving: Sieve the coarse powder through a Pharmacopoeia sieve and pass through a No. 5 sieve to obtain a fine powder with a particle diameter of 0.15 mm.

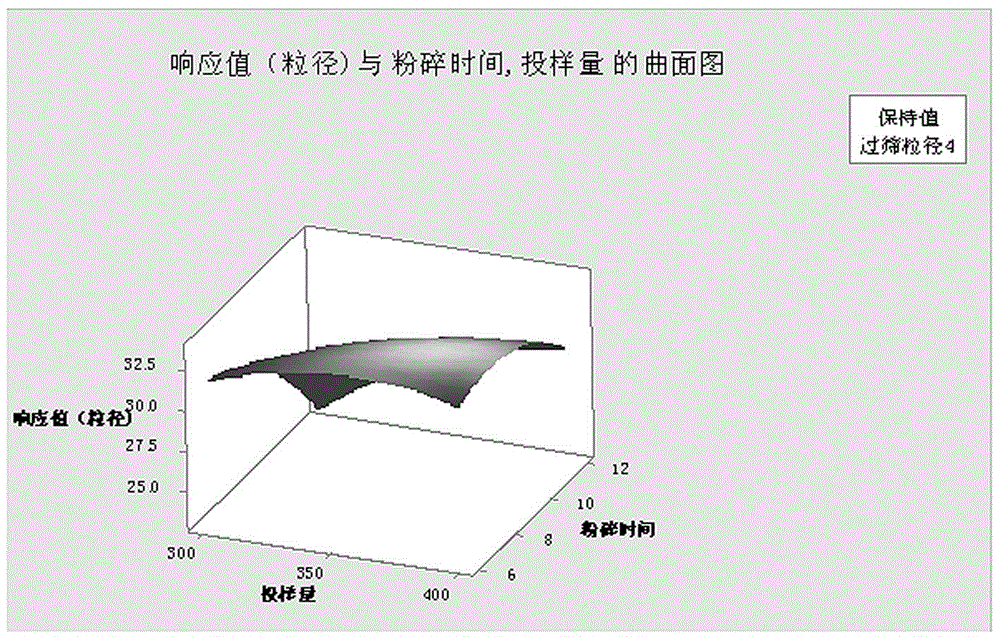

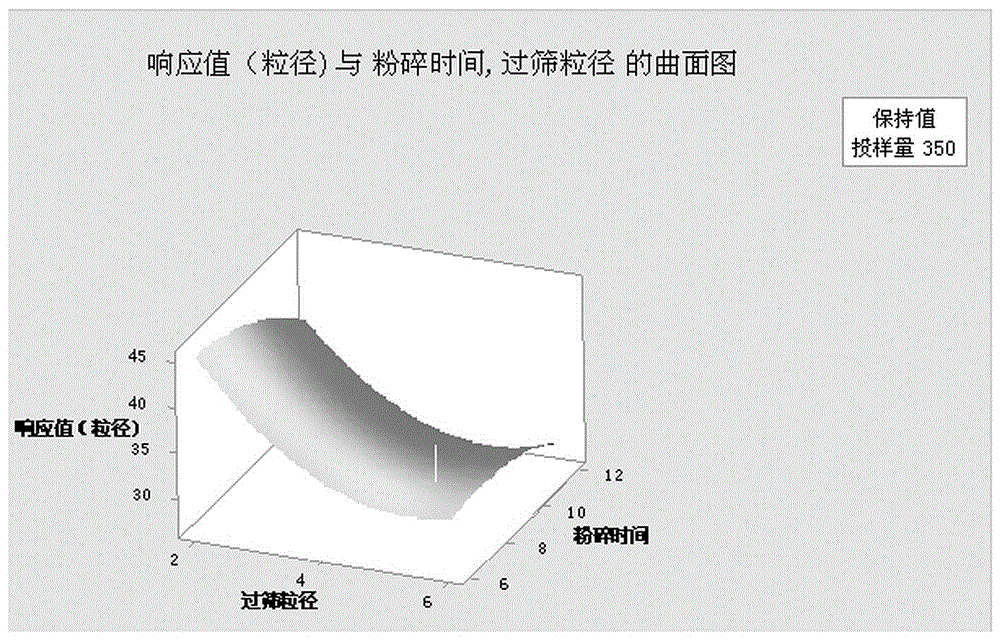

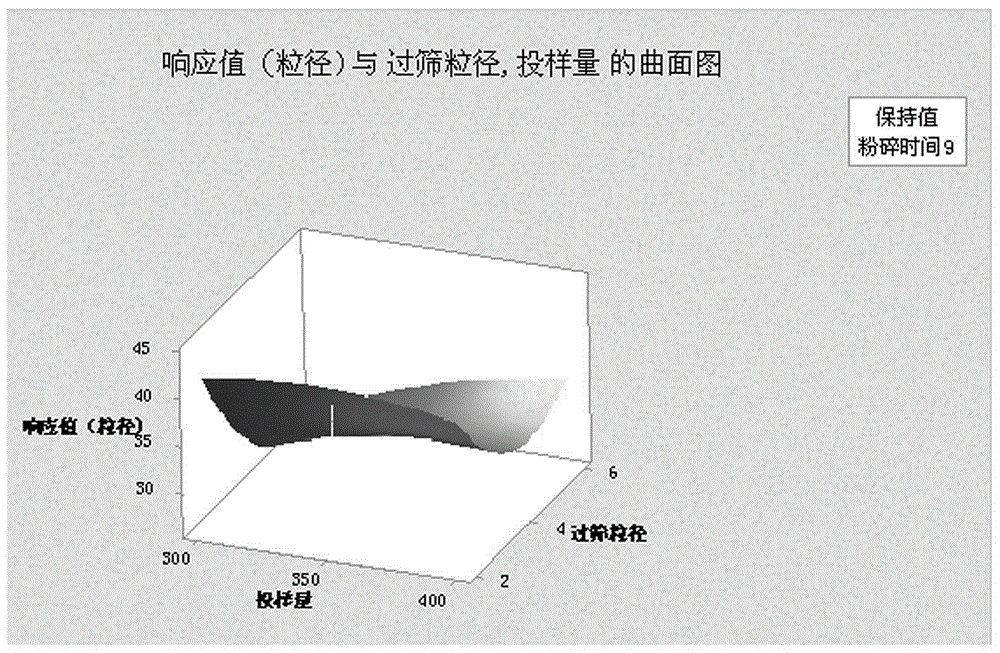

[0056] (4) Superfine pulverization: Put the obtained Coptis chinensis fine powder in a superfine pulverizer, occupying 2 / 3 of the material box, pulverize at -5°C for 12 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com