A kind of casting steel riser covering agent and its preparation and use

A covering agent and cast steel technology, which is applied in the field of metallurgy, can solve problems affecting natural ecological balance, crop production reduction, and surrounding animal and plant hazards, and achieve the effects of good spreadability and heat preservation, small collapse, and small bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method for preparing cast steel riser covering agent is carried out according to the following steps:

[0034] (1) Crushing and grinding the dried raw materials, the particle size is not more than 2mm;

[0035] (2) Weigh each raw material according to the composition quality of the raw material, then mix for 10-20 minutes, stir well, and dry.

Embodiment 1

[0038] The cast steel riser covering agent given in this example, in 100 parts by mass, is composed of the following raw materials: 40 parts of aluminum electrolysis waste cathode carbon blocks, 20 parts of dolomite, 20 parts of vermiculite, and waste and old silicon carbide of aluminum electrolysis - 20 silicon nitride bricks.

[0039] The preparation method for preparing cast steel riser covering agent is carried out according to the following steps:

[0040] (1) Crushing and grinding each raw material to make the particle size within 2mm.

[0041] (2) Weigh each raw material according to the composition quality of the raw material, then mix for 10-20 minutes, stir well, and dry.

[0042] When in use, the cast steel riser covering agent in this embodiment is selected and packaged in a bag of every 20kg. According to the size of the ladle, the amount of the cast steel riser covering agent added is different. After the cast steel riser covering agent is added, a slag layer i...

Embodiment 2

[0045] The cast steel riser covering agent given in this example, in 100 parts by mass, is composed of the following raw materials: 30 parts of aluminum electrolysis waste and old cathode carbon blocks, 30 parts of dolomite, 20 parts of vermiculite, and waste and old silicon carbide of aluminum electrolysis - 20 silicon nitride bricks.

[0046] The preparation method and use method of the cast steel riser covering agent in this embodiment are the same as those in embodiment 1.

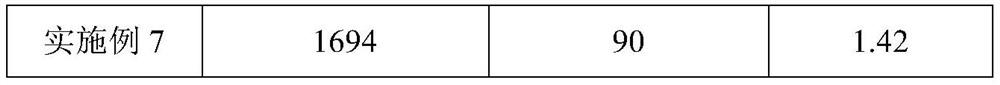

[0047] The performance parameters of the cast steel riser covering agent prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com