Molten steel composite purifying agent for secondary refining and preparing method

A technology of refining and purifying agent outside the furnace, applied in the direction of improving process efficiency, can solve the problems of weak slag foaming ability, low purifying ability of molten steel, weak ability to remove [O], etc. The effect of facilitating processing and promoting slag foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

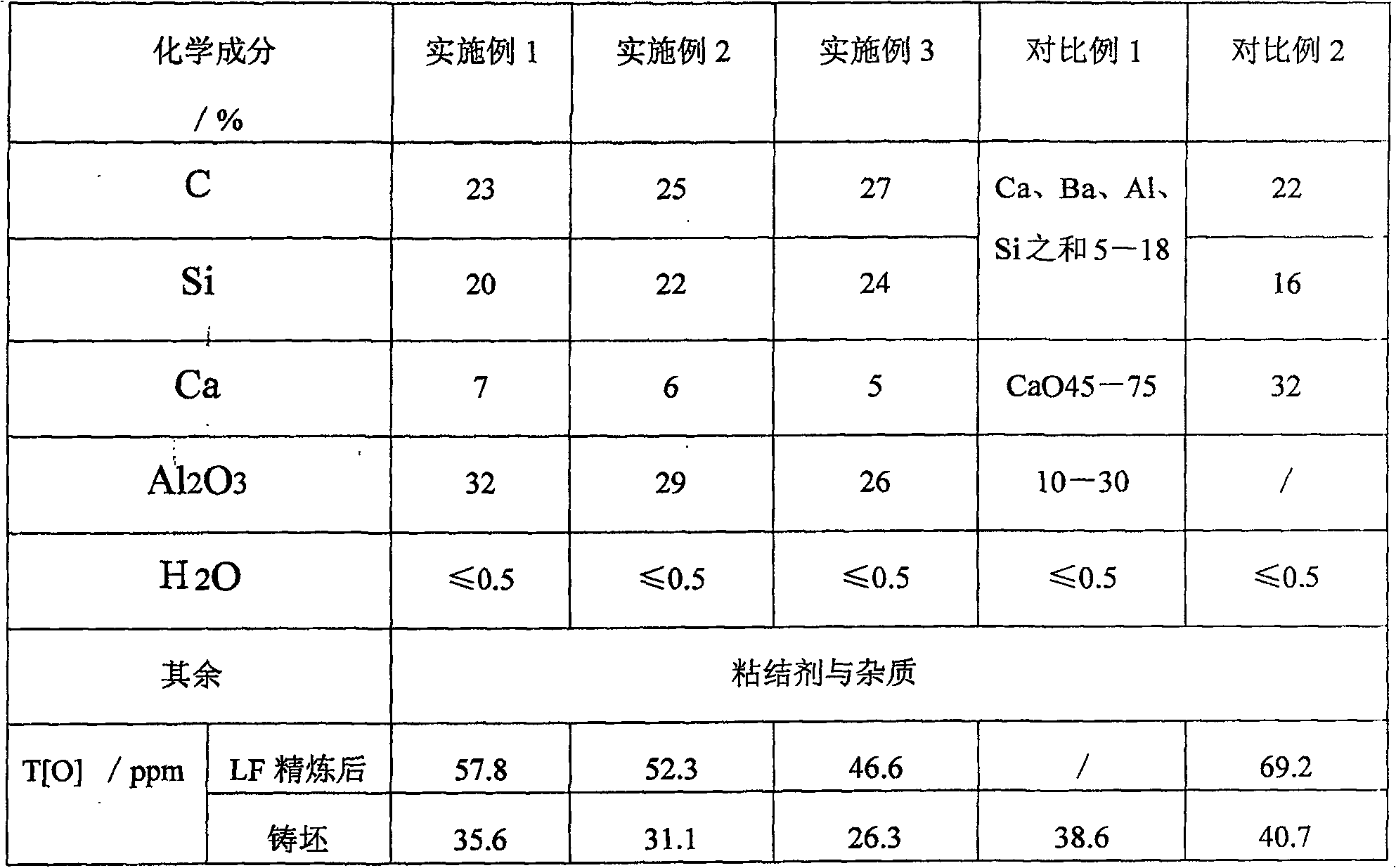

[0046] Under normal temperature and pressure, graphite powder, ferrosilicon FeSi 75 , calcium silicate Ca 28 Si 60 , Put the bauxite in the crusher for crushing, the particle size is greater than 0 and less than 5mm, then send it to the mixer, add the binder for mixing, pelletize the pellets, then dry-stack-inspect-weigh and bag . It is used for refining outside the furnace, and its purification effect is shown in Table 1.

Embodiment 2

[0048] The content of each component specified in the following table 1 repeats the method of the embodiment for refining outside the furnace, and its purification effect is shown in table 1.

Embodiment 3

[0050] The method for repeating the embodiment of each component content specified in the following table 1 is used for refining outside the furnace, and its purification effect is shown in table 1

[0051] Table 1

[0052]

[0053]The cleanliness of steel is generally compared with T[O], the lower the T[O], the cleaner. As can be seen from Table 1, the purification effect of the novel molten steel composite purifying agent of the present invention on molten steel is obviously better than that of the comparative examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com