A method for temperature compensation at the end point of converter blowing

A terminal temperature, converter blowing technology, applied in the direction of manufacturing converters, etc., can solve the problems of decreased alloy yield, prolonged smelting cycle, molten steel peroxidation, etc., to achieve improved alloy yield, shortened smelting cycle, and molten steel temperature. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

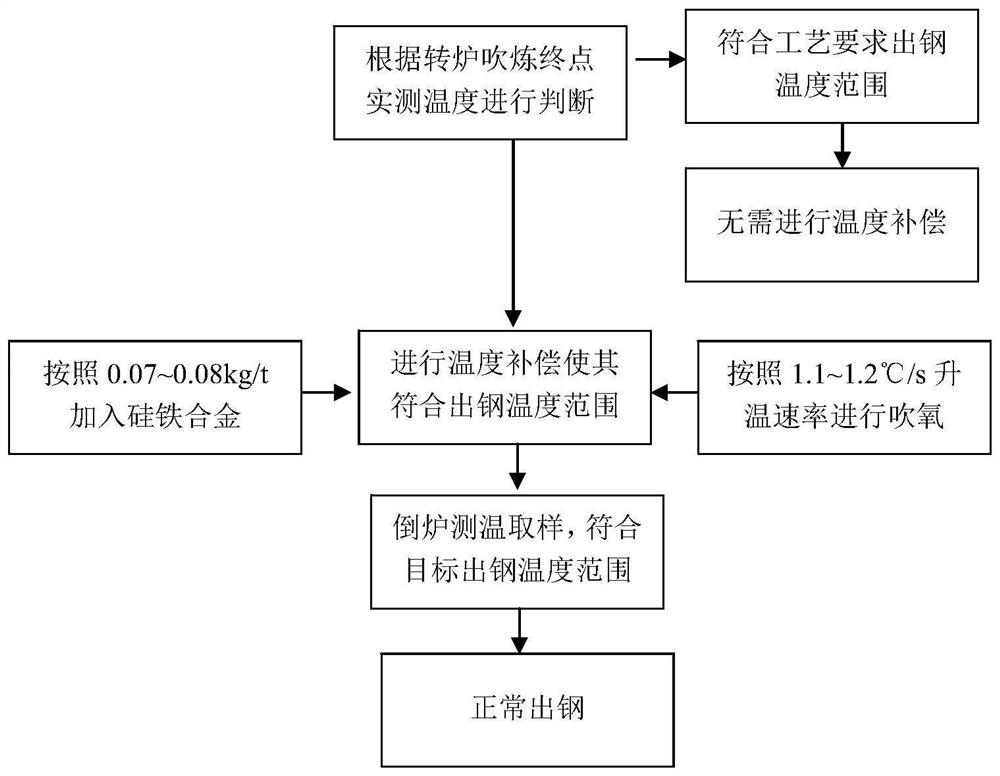

[0030] Such as figure 1 As shown, a method for temperature compensation at the end of converter blowing includes the following steps:

[0031] (1) Measure the carbon content, oxygen content and the end point temperature of the molten steel by the sub-lance of the converter. If the final tapping temperature is met, the steel is directly tapped. Compensation; the final tapping temperature of molten steel is different according to the requirements of different steel types, and is set according to the specific steel type.

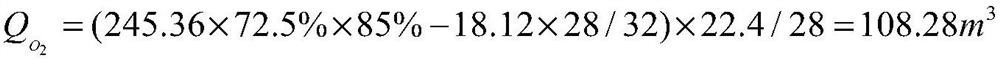

[0032] (2) After measuring the temperature of molten steel, when the oxygen supply intensity is 3.2Nm 3Ferrosilicon alloy is added to molten steel under the condition of / (min·t), preferably, the ferrosilicon alloy is a ferrosilicon alloy with a silicon content of 72.5%; the amount of the ferrosilicon alloy is 0.07kg per 1°C of temperature rise. / t~0.08kg / t; ferrosilicon alloy with high calorific value is used as the exothermic agent, the exothermic element s...

Embodiment 2

[0037] Basically the same as in Example 1, preferably, the ferrosilicon alloy is added into the converter through a high-level silo, the high-level silo includes an alloy silo, the alloy silo is connected to the diversion pipe through a valve, and a resistance wire mesh is arranged in the alloy silo ;When in use, the resistance wire mesh is energized in advance and burned to a red-hot state when feeding is required. The ferrosilicon alloy in the woven bag is hoisted and falls on the resistance wire mesh. The bottom of the woven bag is burnt, and the ferrosilicon alloy falls into the alloy silo. When the valve is opened, the ferrosilicon alloy flows into the converter through the diversion pipe, which realizes the online adjustment of the ferrosilicon alloy during the molten steel smelting process. The whole feeding process does not need to be powered off and other operations, so that the operation of adding the ferrosilicon alloy to the converter is simple and fast, improving W...

Embodiment 3

[0040] When the converter is blowing to the end, since the residual heating elements in the steel mainly include C and Mn content are oxidized to a low level, by adding a ferrosilicon alloy with a higher heating value and a silicon content of 72.5% into the converter as a heating agent, Use the chemical heat generated by the reaction of the heating element silicon and oxygen to increase the temperature of the molten steel in the converter pool, and the silicon in the ferrosilicon heating agent reacts with oxygen to form SiO 2 Entering the slag has almost no effect on the composition of the rough smelting molten steel, which is conducive to improving the physical quality of the molten steel. Through the statistics and analysis of a large number of experimental data, the present invention measures the corresponding relationship between the carbon content of different endpoints and the oxygen level of molten steel, the excess index of the ferrosilicon heating agent when it reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com