Laser-assisting type ultrasonic additive manufacturing device for metallic foil tape and manufacturing method

A metal foil strip and laser-assisted technology, applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc., can solve the problems of high price, restriction of technology development and application, and decrease of connection strength, so as to increase the thickness of the diffusion layer and avoid Effect of as-cast structure and effective temperature monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] The invention provides a laser-assisted ultrasonic additive manufacturing device and a manufacturing method of a metal foil strip, and the specific implementation methods are as follows:

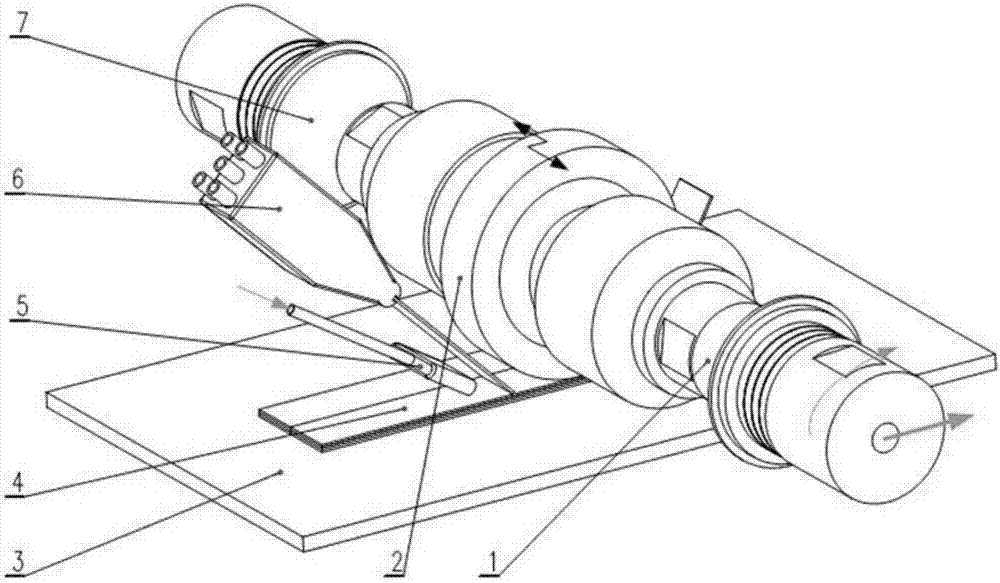

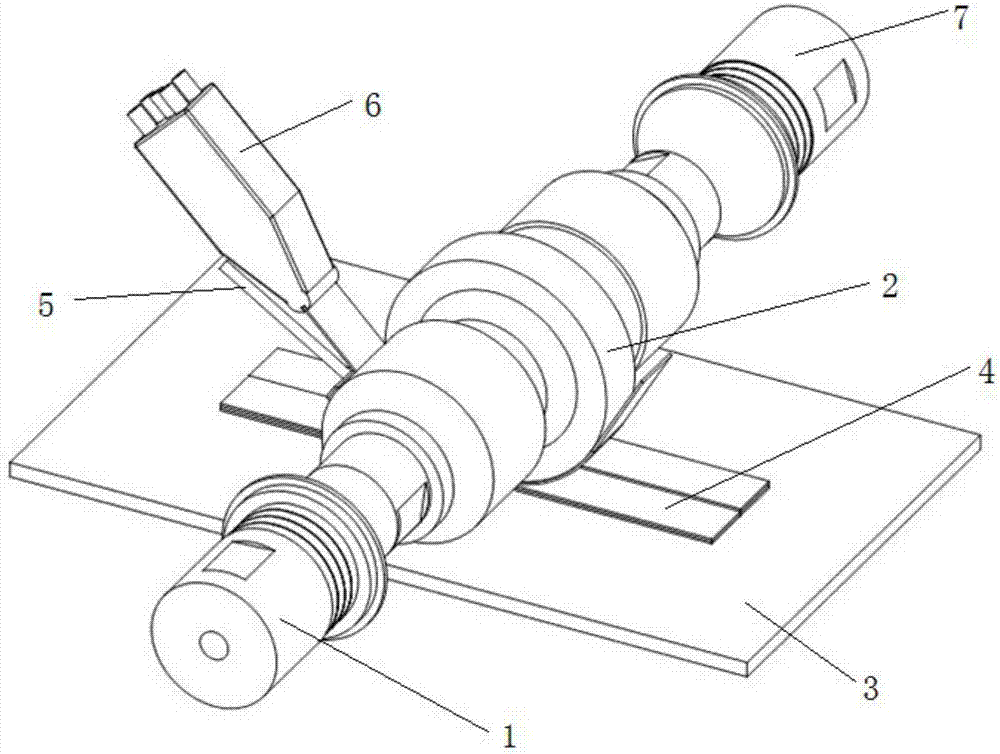

[0025] Such as figure 1 and figure 2 As shown, the laser-assisted ultrasonic additive manufacturing device for metal foil strips includes a workbench 3, and an ultrasonic rolling head 2 positioned on the workbench 3 and an ultrasonic transducer-1 and an ultrasonic transducer installed at two ends of the ultrasonic rolling head 2. Ultrasonic transducer two 7, the rear of the ultrasonic roll welding pressure head 2 is provided with a scanning laser head 6 and a shielding gas device 5, the scanning laser head 6 and shielding gas device 5 are connected with the ultrasonic transducer one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com