Acoustic surface wave sensor with double sensitive sources

A surface acoustic wave and sensitive source technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to measure multiple parameters, increase the complexity and difficulty of system design, and achieve strong stability and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

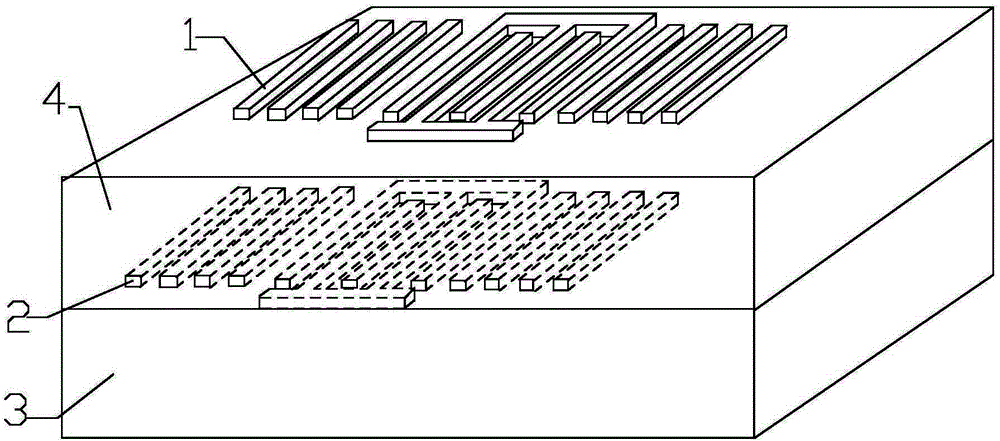

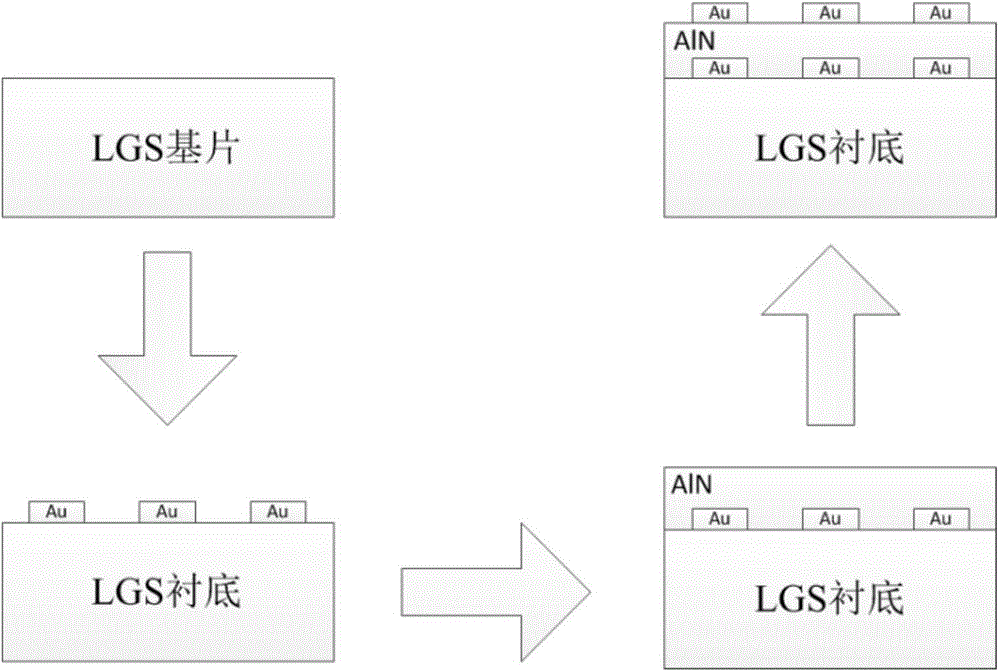

[0015] Such as figure 1 As shown, the surface acoustic wave sensor with dual sensitive sources of the present invention comprises an LGS substrate 3 on which an interface resonator 2 and an AlN thin film layer 4 are arranged, and the AlN thin film layer 4 completely covers the interface resonator 2, and the AlN thin film A surface resonator 1 is provided on the layer 4, and the vertical projection of the surface resonator 1 coincides with the vertical projection of the interface resonator 2, and the interface resonator 1 and the surface resonator 1 are both the same surface acoustic wave The resonator, the metal film electrode in the surface acoustic wave resonator is made of gold.

[0016] AlN thin films and LGS substrates have different surface acoustic wave propagation characteristics, so their responses to stress and temperature are dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com