Electromagnetic cooker structure capable of accurately measuring temperature

A technology of precise temperature measurement and induction cooker, applied in the field of induction cooker, can solve the problems of inaccurate temperature control, slow disappearance, effective control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

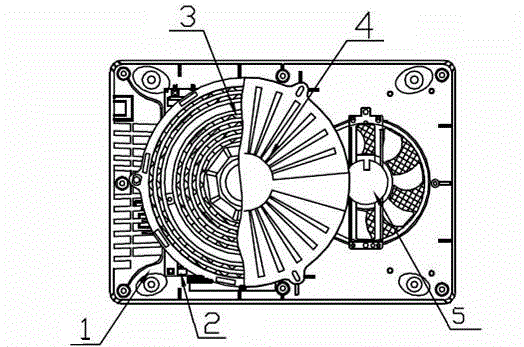

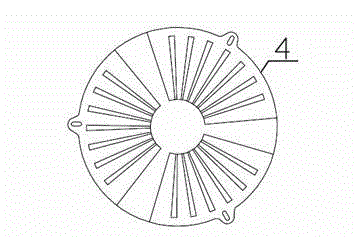

[0014] An induction cooker structure capable of accurate temperature measurement, comprising a matched and connected induction cooker lower shell 1, an induction cooker upper cover ceramic plate, an induction cooker power supply board 2, a main control board, an induction cooker coil plate 3, an induction cooker fan 5, and an induction cooker arranged in the middle of the induction cooker coil plate The NTC sensor probe, the induction cooker power board 2, the induction cooker fan 5 and the NTC sensor probe are all connected to the main control board. The lower surface of the ceramic plate of the upper cover of the induction cooker is covered with a metal foil 4 with good thermal conductivity and poor magnetic conductivity, which can be aluminum foil or copper foil, as long as it is ensured that the metal foil 4 does not generate heat or the heat is very high when the induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com