Anti-erosion mullite brick for blast furnace and preparation method thereof

A mullite brick, anti-corrosion technology, applied in the field of mullite bricks, can solve the problems of poor high temperature performance, low strength, weak impermeability, etc., to achieve longevity, low porosity, and strong impermeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

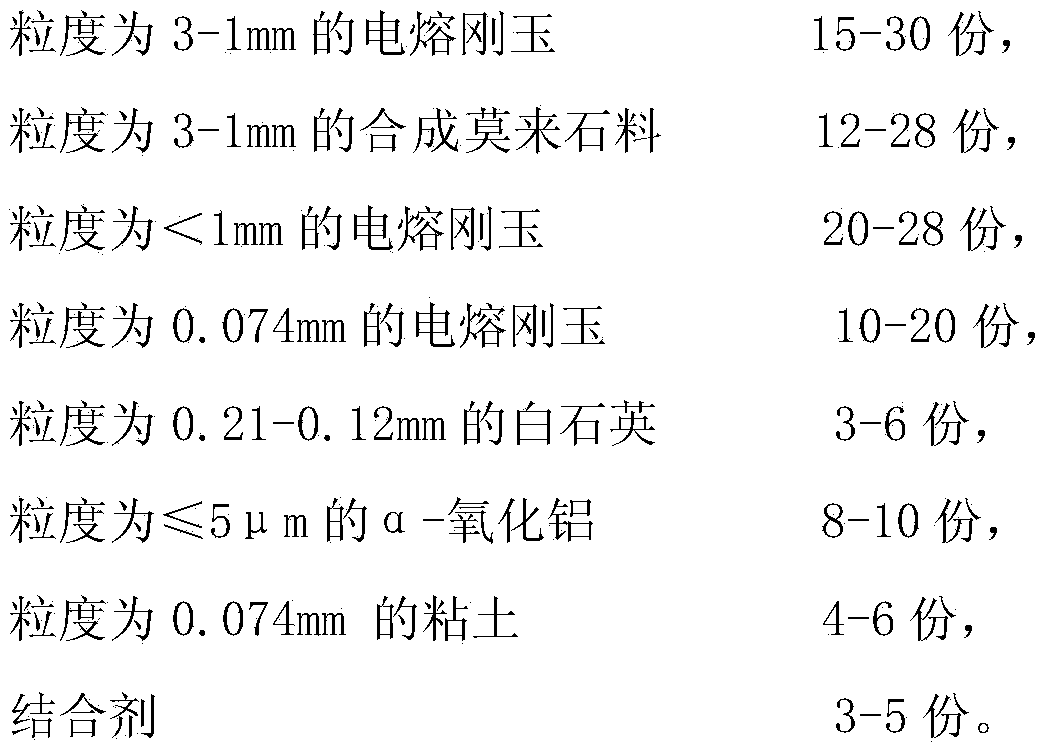

[0027] The anti-corrosion mullite brick described in this embodiment consists of the following raw materials in parts by weight:

[0028] 15 parts of fused corundum with a particle size of 3-1 mm, 28 parts of synthetic mullite with a particle size of 3-1 mm, 20 parts of fused corundum with a particle size of <1 mm, 20 parts of fused corundum with a particle size of 0.074 mm, and a particle size of 0.21 - 3 parts of white quartz with a particle size of 0.12mm, 10 parts of α-alumina with a particle size of ≤5μm, 4 parts of clay with a particle size of 0.074mm, and 3.5 parts of binder pulp.

[0029] The preparation steps of anti-corrosion mullite brick are as follows:

[0030] Fused corundum with a particle size of 0.074mm, white quartz with a particle size of 0.21-0.12mm, α-alumina with a particle size of ≤5μm, and clay with a particle size of 0.074mm are pre-mixed together and mixed in a double-screw mixer. Prepare for 10 minutes to fully mix the fine powder and disperse the f...

example 1

[0032] Example 1 detection data: Al 2 o 3 Content 83.46%, Fe 2 o 3 Content 0.54%; load softening start temperature above 1700℃; porosity 12.2%; bulk density 3.07g / cm 3 ; Compressive strength 125MPa; Linear change rate (1450℃*3h) 0.1%.

Embodiment 2

[0034] The anti-corrosion mullite brick for blast furnace described in this embodiment is composed of the following raw materials in parts by weight:

[0035] 22 parts of fused corundum with a particle size of 3‐1mm, 21 parts of synthetic mullite with a particle size of 3‐1mm, 23 parts of fused corundum with a particle size of 1‐0mm, 15 parts of fused corundum with a particle size of 0.074mm, and a particle size of 5 parts of 0.21-0.12mm white quartz, 9 parts of high-temperature alumina with a particle size of ≤5μm, 5 parts of clay with a particle size of 0.074mm, and 4.5 parts of binder pulp.

[0036] The preparation steps of anti-corrosion mullite brick are as follows:

[0037] Fused corundum with a particle size of 0.074mm, white quartz with a particle size of 0.21-0.12mm, α-alumina with a particle size of ≤5μm, and clay with a particle size of 0.074mm are pre-mixed together and mixed in a double-screw mixer. Prepare for 15 minutes to fully mix the fine powder and disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com