Special economical pressure regulating valve for welding heat-insulating gas cylinder

A technology of hot gas cylinder and pressure regulating valve, applied in valve details, safety valve, balance valve, etc., can solve the problems of short service life of diaphragm, poor sealing effect, slow pressurization speed, etc. Longevity guarantee and deformation reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

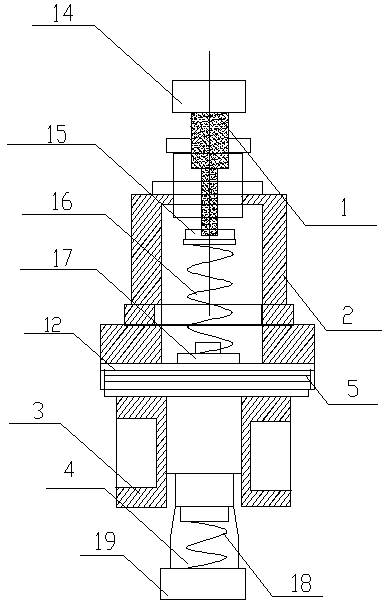

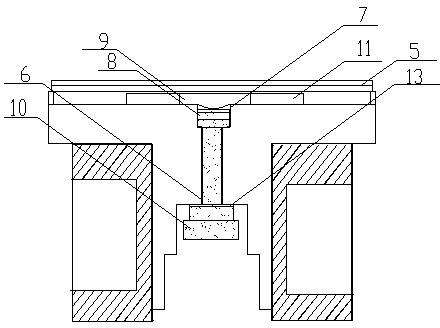

[0017] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0018] Such as figure 1 and figure 2 As shown, this embodiment provides an economical pressure regulating valve for welding insulated gas cylinders, including a regulator 1, a valve cover 2, a valve body 3 and a valve seat 4, the regulator 1 runs through the valve cover 2, and the valve cover 2 and the valve body 3 are fitted through their own threads, the valve seat 4 is screwed into the bottom of the valve body 3, and the middle part of the top surface of the valve body 3 is provided with a protruding limiting platform boundary 11, so The top surface of the valve body 3 is provided with a diaphragm 5, and the middle part of the valve body 3 is provided with a val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com