Coal blending method of 7.63m coke oven during starting work

A technology of coal blending and coke oven, which is applied in the field of coking and can solve the problems of lack of research on reasonable coal blending schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

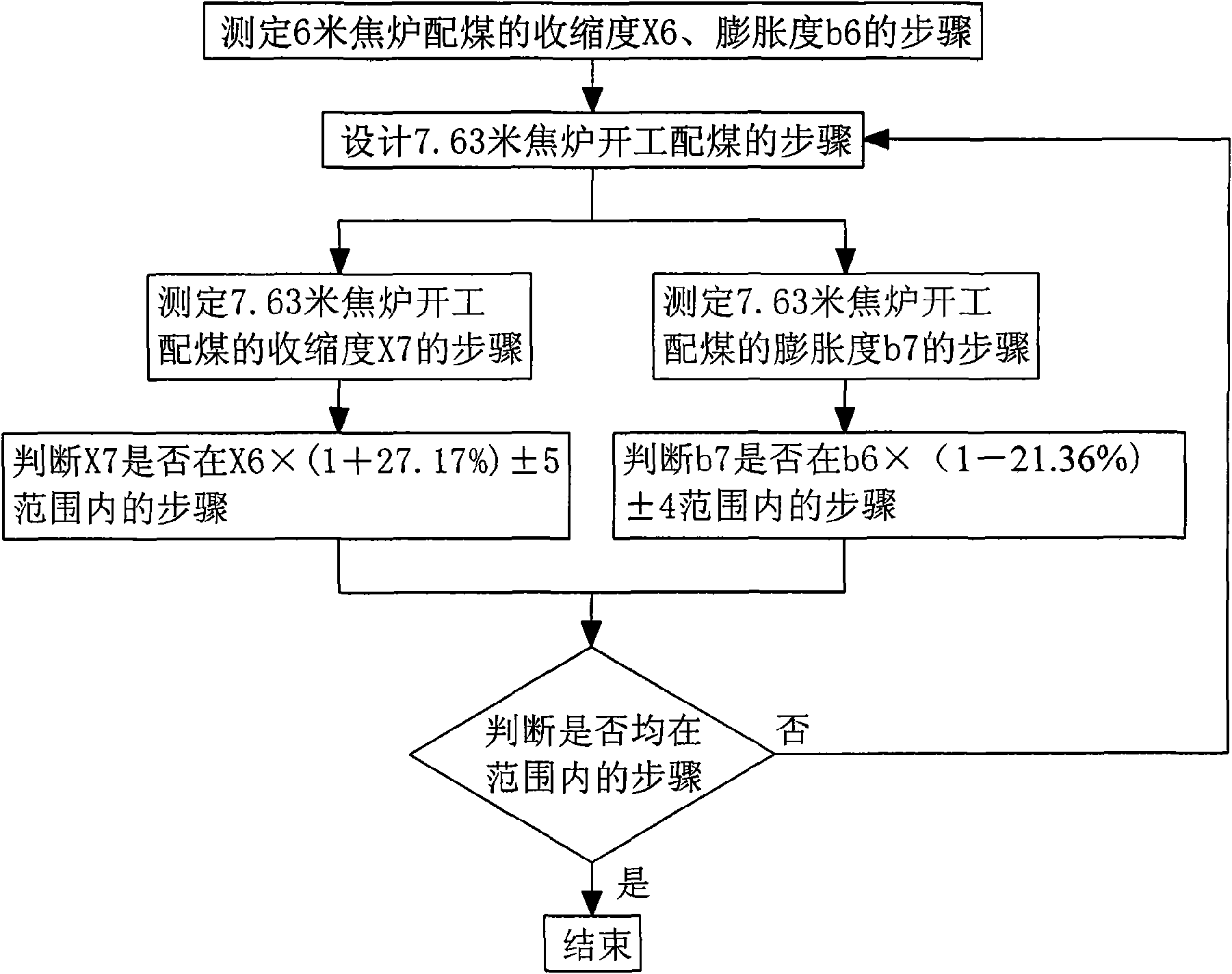

[0028] Such as figure 1 Shown 7.63 meters coke oven start-up coal blending method, it comprises the following steps:

[0029] Step (1), measure X 6 , b 6 steps; the X 6 Shrinkage of coal blending for 6m coke oven, b 6 The expansion degree of coal blending for 6m coke oven;

[0030] Step (1.1), the step of measuring the degree of shrinkage and the degree of expansion of each 6-meter coke oven coal blending over two months;

[0031] Step (1.2), the step of calculating the average value, get X 6 and b 6 .

[0032] According to the coal blending designed by the previous 6-meter coke oven coal blending institute, a small sample was made, and X was determined. 6 , b 6 It can be determined in the laboratory by using the method specified in GBT 479-2000 "Measurement Method for Colloidal Layer Index of Bituminous Coal" or GBT 5450-1997 "Aoa Dilatometer Test for Bituminous Coal". Step (1) can also directly use the test data of the 6-meter coke oven coal blending in recent mont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com