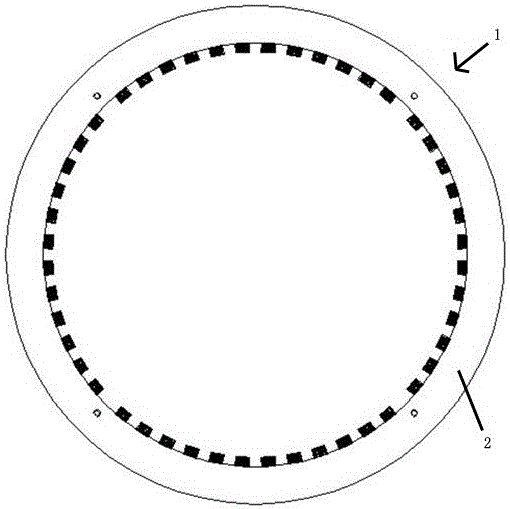

Ultra-thin side circuit conductive ring

A conductive ring and circuit technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem that the thickness of the conductive ring cannot be reached, and achieve the effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

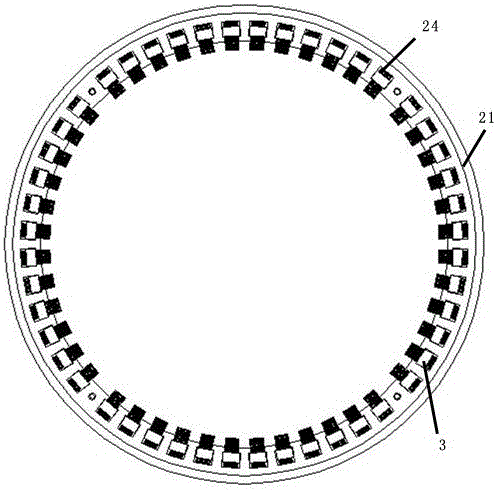

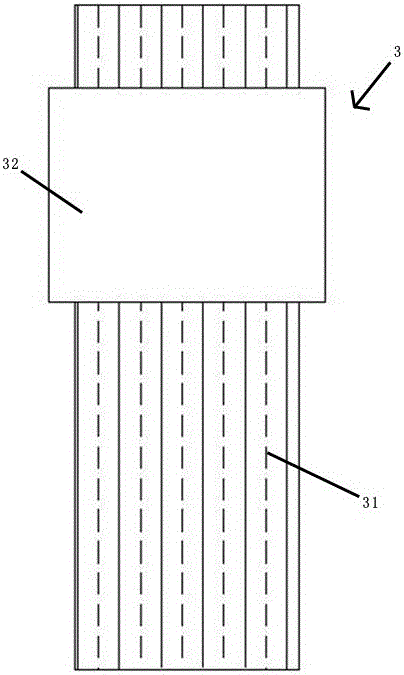

[0027] The annular outer cover (2) includes a front outer cover (21) and a rear outer cover (22), and a fixing member is provided on the inner circumference of the front outer cover (21) or the rear outer cover (22), and the fixing The part is the fixing groove (24), the copper sleeve (32) is placed behind the fixing groove (24), the front outer cover (21) and the rear outer cover (22) are closed and locked, and the conductive fiber bundle (31) is It is fixed on the annular outer cover (2) by the conductive sleeve.

Embodiment 2

[0029] Such as figure 2 and Figure 5 As shown, the annular outer cover (2) includes a front outer cover (21), a fixing ring (23) and a rear outer cover (22), such as Figure 4 The shown fixing ring (23) is evenly distributed with fixing pieces, the fixing piece is a fixing groove (24), the copper sleeve (32) is placed behind the fixing groove (24), and the fixing ring is placed on the front outer cover ( 21) Between the rear outer cover (22), softly lock the front outer cover and the rear outer cover, and the conductive fiber bundle (31) is fixed on the annular outer cover through the conductive sleeve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com