Sensible heat recovering system and method of tail gas of converter with afterburning

A converter tail gas and sensible heat recovery technology, which is applied to furnaces, waste heat treatment, furnace components, etc., can solve the problems of heavy maintenance and repair work, short service life of vaporization flue, and heavy maintenance and replacement work. The effect of reducing alternating thermal stress, occupying a small area, and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

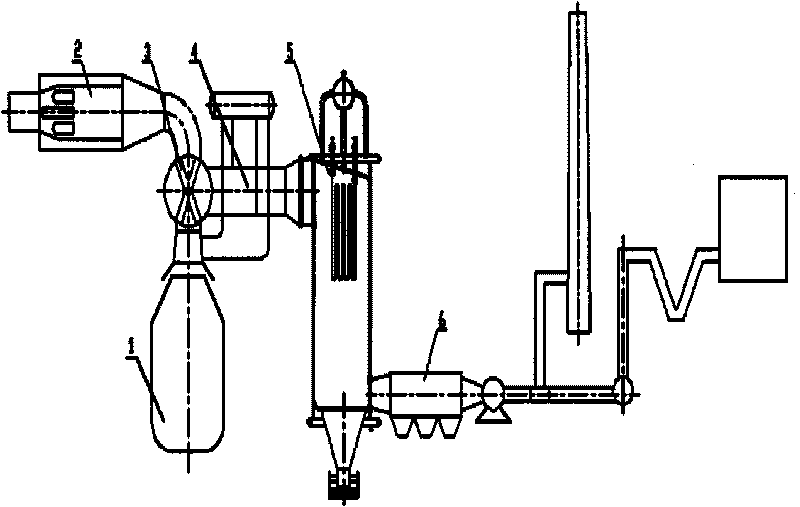

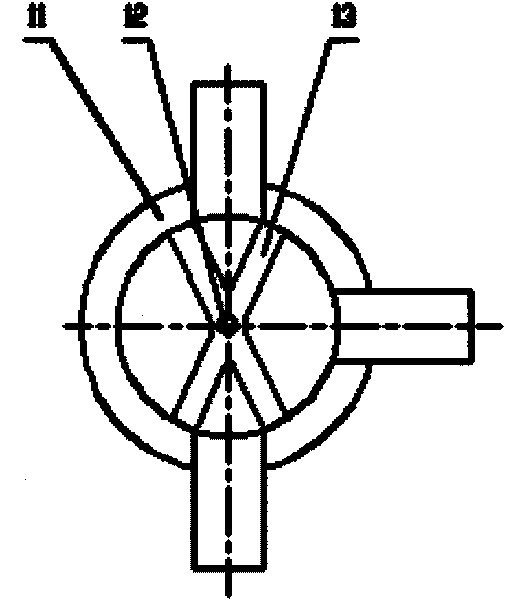

[0031] figure 1 It is a schematic general diagram of a converter tail gas sensible heat recovery system and method with supplementary combustion involved in the present invention. The system includes a converter 1, a vaporization flue 4, a cooling device 5 connected to the vaporization flue, an exhaust dust removal, recovery and discharge system 6, a supplementary combustion chamber 2 and a water-cooled three-way valve 3, the two of the water-cooled three-way valve The two inlets are respectively connected with the supplementary combustion combustion chamber and the outlet of the converter tail gas, and the outlet of the water-cooled three-way valve is connected with the vaporization flue. The post-combustion combustion chamber 2 adopts a regenerative channel burner.

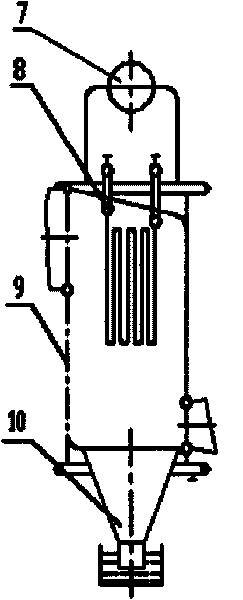

[0032] The post-combustion combustion chamber 2 adopts a regenerative channel burner; the cooling device 5 adopts a waste heat boiler, which is composed of a drum 7 , a steam superheater 8 , a membrane water wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com