Blocking device for drainage gas recovery of horizontal well velocity string

A technology of velocity pipe string drainage and horizontal well, which can be used in earth-moving drilling, wellbore/well components, sealing/packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

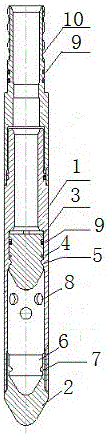

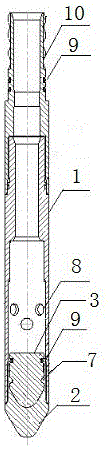

[0019] In order to solve the problem of air leakage and shedding caused by the plug scraping the tubing wall in the inclined well section during the running operation of the velocity string, this embodiment provides a figure 1 with figure 2 The shown plugging device for horizontal well velocity pipe string drainage and gas production includes a cylindrical shell 1, the bottom end of which is threaded to connect the guide head 2, and the shell 1 is provided with a plurality of sieve holes 8, and the inner cavity A plug 3 is provided, and the outer wall of the plug 3 is connected with the inner wall of the housing 1 by a pin 4. The outer wall of the plug 3 is provided with two slots 5, and the two slots 5 are symmetrical about the axial centerline of the plug 3. ;

[0020] Such as figure 1 As shown, the top of the guide head 2 is provided with a pocket 6, the opening of the pocket 6 is upward, the bottom surface is in contact with the top surface of the guide head 2, the pock...

Embodiment 2

[0026] On the basis of Embodiment 1, in order to facilitate machining and installation of various components, the housing 1 is composed of an upper half and a lower half connected by screws.

Embodiment 3

[0028] On the basis of Example 1, such as figure 1 with figure 2 As shown, in order to avoid the occurrence of plugging air leakage and ensure its tightness, the outer wall of the upper half of the housing 1 and the outer wall of the plug 3 are all provided with annular grooves, and O is sleeved in the annular grooves. Type sealing ring 9.

[0029] Three progressively deeper grooves 10 are opened on the upper outer wall of the housing 1 . After the plug is assembled as a whole, the velocity string is rolled to three progressively deeper grooves 10 in sequence by means of a rolling tool. The upper part of the plug adopts the groove design, and the connection between the whole body and the velocity string is adopted to ensure that the connection between the plug and the velocity string is firm and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com