A method and device for gas recovery with plunger gas lift with velocity string and drainage

A velocity pipe string drainage and velocity pipe string technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem that the wellbore fluid cannot be completely eliminated, and achieves low cost, simple method and improved effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

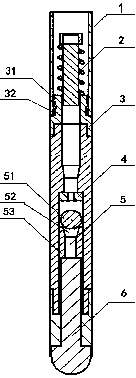

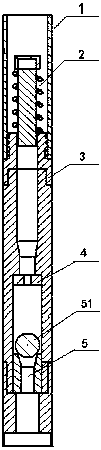

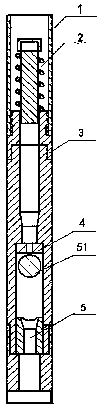

[0031] In order to overcome the problem that the existing tools cannot eliminate the accumulation of liquid about 150m below the adapter, and reduce the effect of the plunger gas lift drainage gas recovery and gas well production, the present invention provides: figure 1 Shown is a speed pipe string matching plunger gas lift drainage gas recovery method and device. The present invention solves the problem that the velocity pipe string drainage gas recovery or plunger gas lift drainage gas recovery technology alone cannot completely eliminate the wellbore fluid accumulation, and This method can solve the problem of drainage and gas recovery during the entire life cycle of a gas well from production to abandonment. The method is simple, fast, and low in cost. It does not require a riser speed string, and due to the increase in the depth of the plunger, the use of plungers can be improved. The drainage and gas recovery effect of gas lift.

[0032] A method for gas-lifting drainage an...

Embodiment 2

[0048] On the basis of Example 1, in this example, the step is to use the coiled tubing 1 with a diameter of 38.1 mm as the velocity string drainage gas production.

[0049] In the fifth step, when the gas production volume of the gas well is less than 2000m 3 / d, put a φ28mm ball plug 7 inside the speed column on the ground.

[0050] In the third step, the coiled tubing 1 is run into the wellbore by the coiled tubing operating machine and passed through the downhole tool until it runs to 8 m above the middle of the gas layer.

[0051] A speed pipe string supporting plunger gas lift drainage gas recovery device, comprising a buffer 2, a receiver 3, a spherical one-way valve 5 and a plug 6, the buffer 2, a receiver 3, a spherical one-way valve 5 and The plugs 6 are connected sequentially from top to bottom. The above-mentioned integrated devices are all preset to the bottom end of the coiled tubing 1; wherein the buffer 2 is internally locked and connected to the receiver 3, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com