Plunger

A plunger and jacket technology, applied in the field of gas production tools, can solve the problems that the plunger cannot slide freely, it is difficult to adapt to deep wells or ultra-deep wells, etc., and achieve the effect of increasing the scope of use and improving the effect of drainage and gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

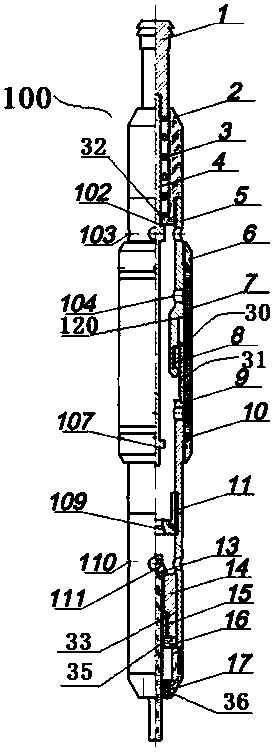

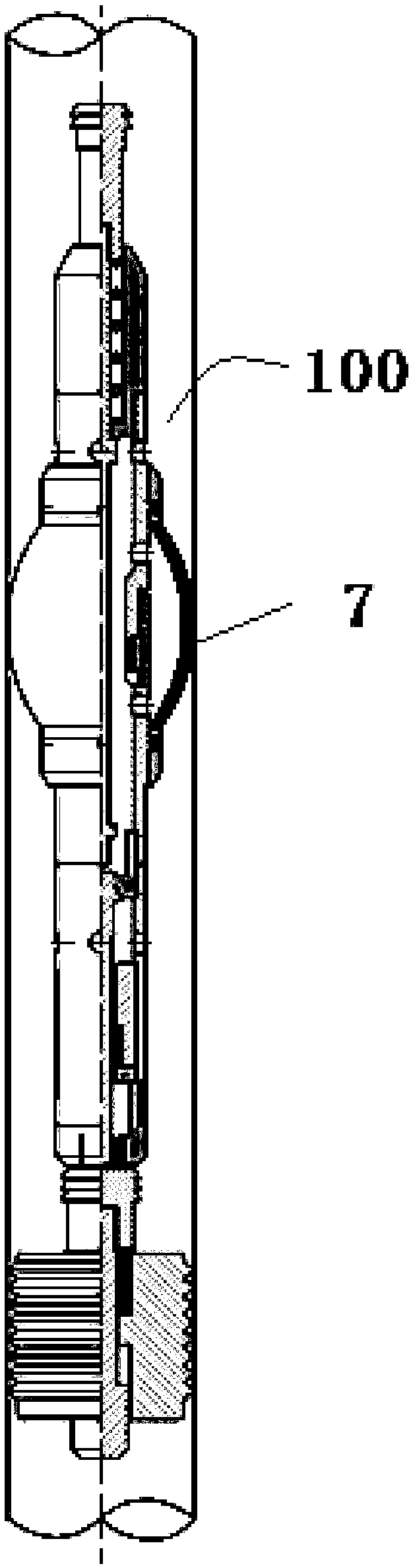

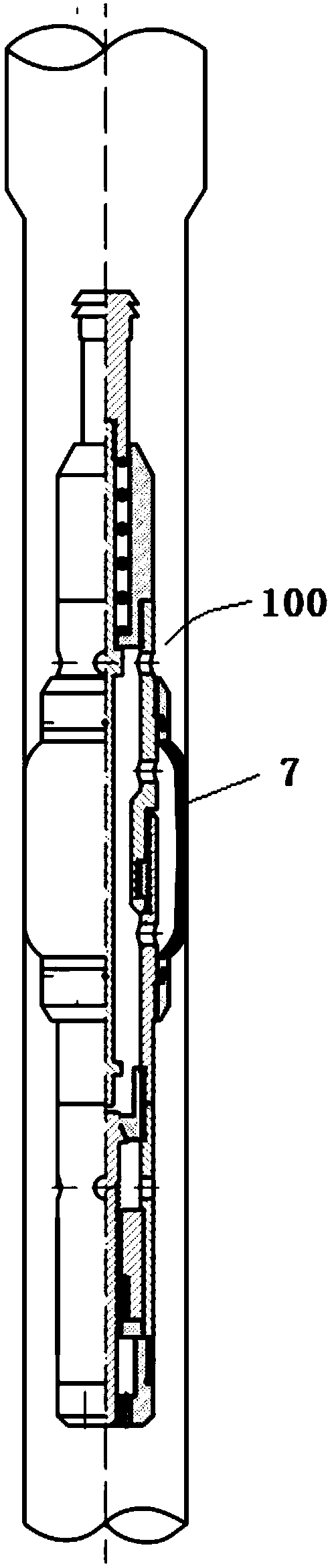

[0033] figure 1 A plunger 100 according to the invention is shown. Such as figure 1 As shown, the plunger 100 includes a fishing neck 1 , an upper casing 5 , a lower casing 9 and a cartridge assembly 30 . Wherein, the salvage neck 1 is columnar. The upper casing 5 is cylindrical, arranged at the lower end of the fishing neck 1, and can move axially relative to the fishing neck 1. A first communication hole 103 communicating with the inside and outside is provided on the wall of the upper casing 5 . The lower jacket 9 is cylindrical and is arranged on the lower end of the upper jacket 5 , and its inner cavity communicates with the inner cavity of the upper jacket 5 . Furthermore, the lower casing 9 is configured to be able to move relative to the upper casing 5 in the axial direction. A second communication hole 110 is provided on the wall of the lower outer casing 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com