Low-temperature liquefaction system for dual cycle of mixed working medium

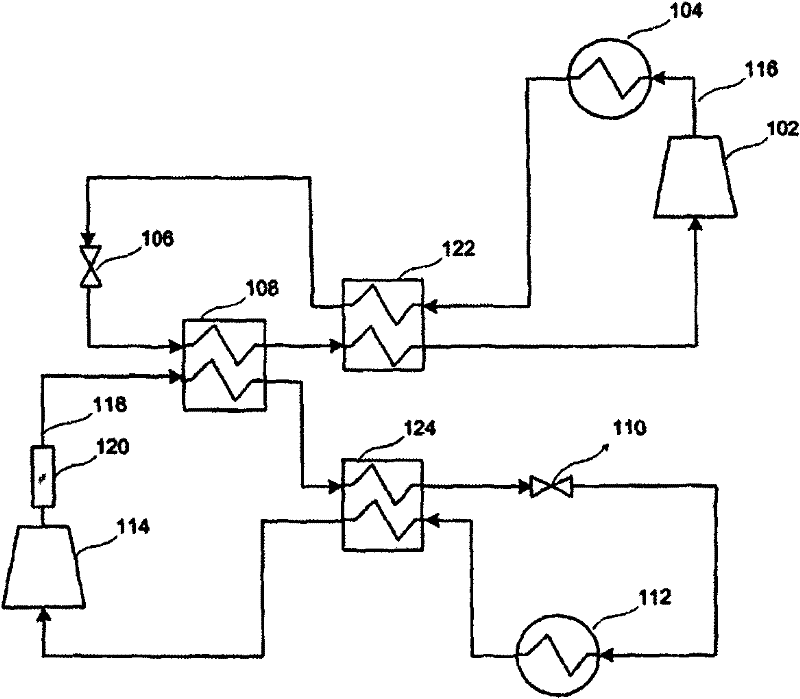

A mixed working medium and double cycle technology, which is applied in refrigeration and liquefaction, compressors with cascading work, lighting and heating equipment, etc., can solve the problems of multiple cycle structure equipment, unreasonable temperature load distribution, complex structure, etc. , to achieve the effect of improving system safety, avoiding heat transfer temperature difference, and making the system simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The air is liquefied by using the low-temperature liquefaction system with mixed working medium double circulation provided by the present invention.

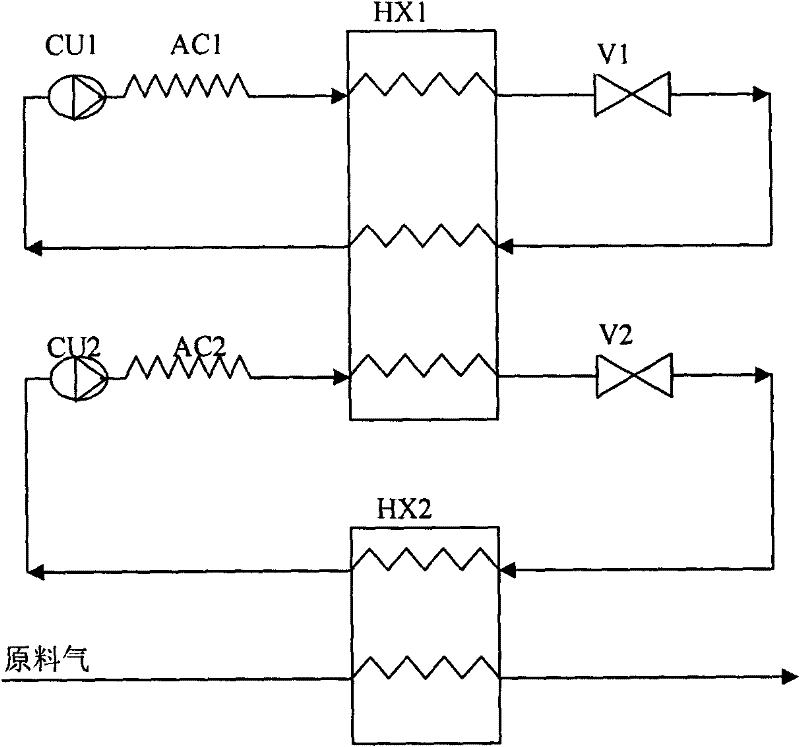

[0032] The mixed refrigerant used in the first refrigeration cycle of this embodiment 1 is composed of nitrogen, methane, ethane, propane and butane, and the mixed refrigerant is compressed by the first compressor CU1 to high temperature and high pressure , enter the first condenser AC1 to cool to normal temperature, then enter the main heat exchanger HX1 to be gradually cooled, and then enter the first throttling valve V1 through the pipeline to throttle and cool down, becoming a low-temperature and low-pressure refrigerant, and then the low-temperature and low-pressure refrigerant enters The main heat exchanger HX1 cools the high-pressure mixed refrigerant and serves as the circulating working medium in the second refrigeration cycle. After rewarming itself, it enters the compressor to complete a refrigeration cycle (th...

Embodiment 2

[0036] Example 2: Coalbed methane (or natural gas) is liquefied by using the low-temperature liquefaction system provided by the present invention using mixed working fluid double circulation.

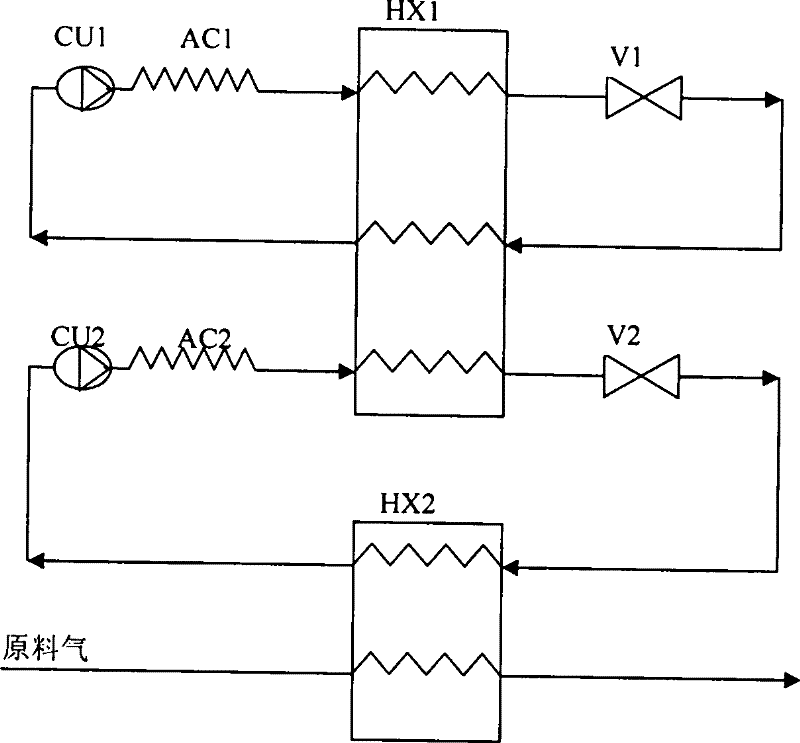

[0037] like figure 2 As shown in the low-temperature liquefaction system using mixed working medium double cycle, the connection mode of the first refrigeration cycle and the second refrigeration cycle is the same as that of embodiment 1; in this embodiment 2, the first refrigeration cycle uses the mixed refrigerant as nitrogen , methane mixed refrigerant (mixed refrigerant composed of any two or any three of nitrogen, methane, ethane, propane and butane is acceptable)

[0038] The coalbed methane after simple dedusting treatment enters the distributed heat exchanger HX2, and is cooled and liquefied by the low-temperature two-phase working fluid in the distributed heat exchanger HX2, and the liquefied coalbed methane / natural gas finally passes through the outlet of the distributed hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com