Ultra-low temperature freezer, refrigeration system and vacuum apparatus

An ultra-low temperature refrigeration and refrigerant technology, applied in the field of refrigeration systems, vacuum devices, and ultra-low temperature refrigeration devices, can solve the problems of insufficient buffer tank capacity, reduced cooling efficiency, prolonged cooling time, etc., to prevent gas refrigerant from staying in the buffer tank. The effect of reducing cooling efficiency and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

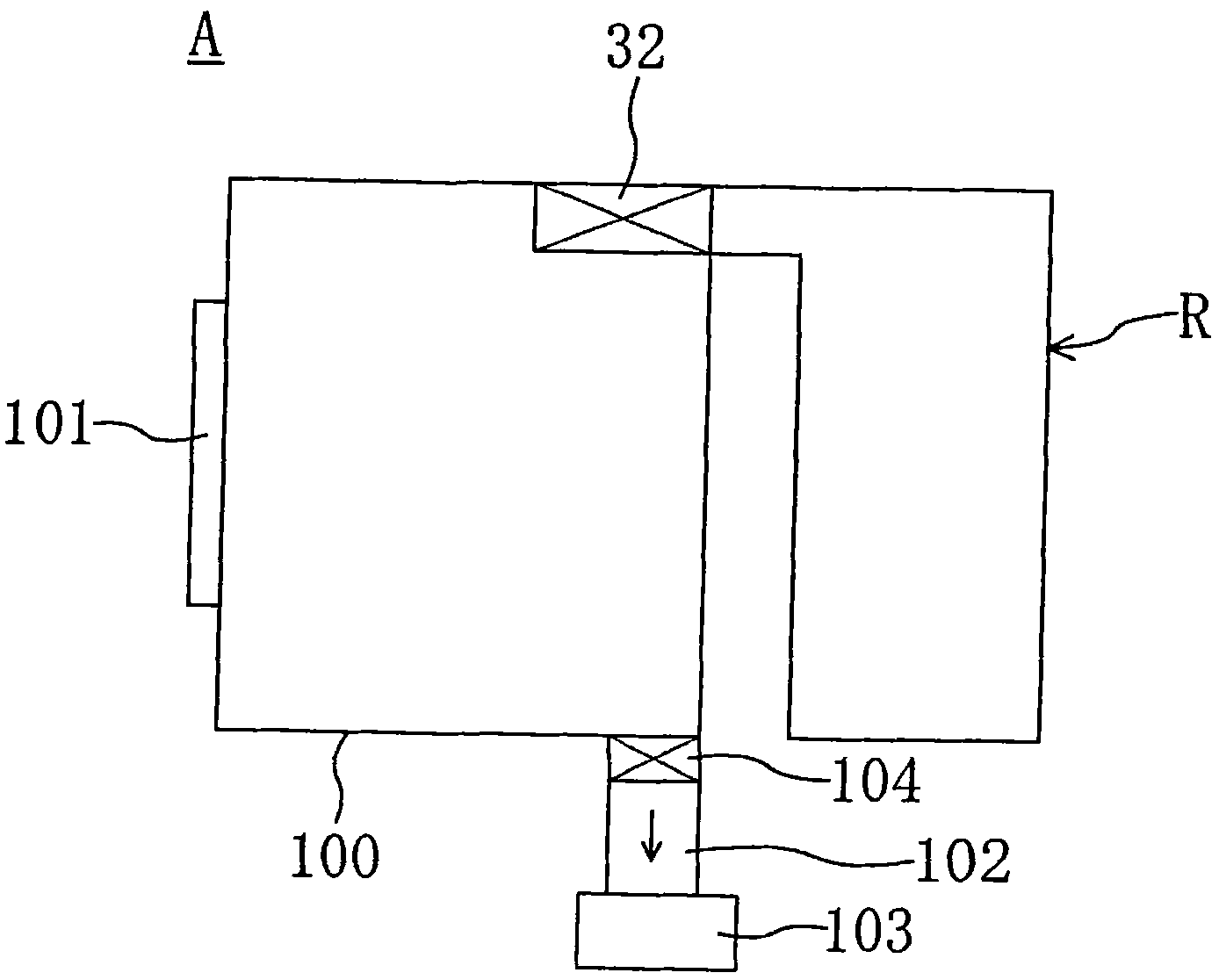

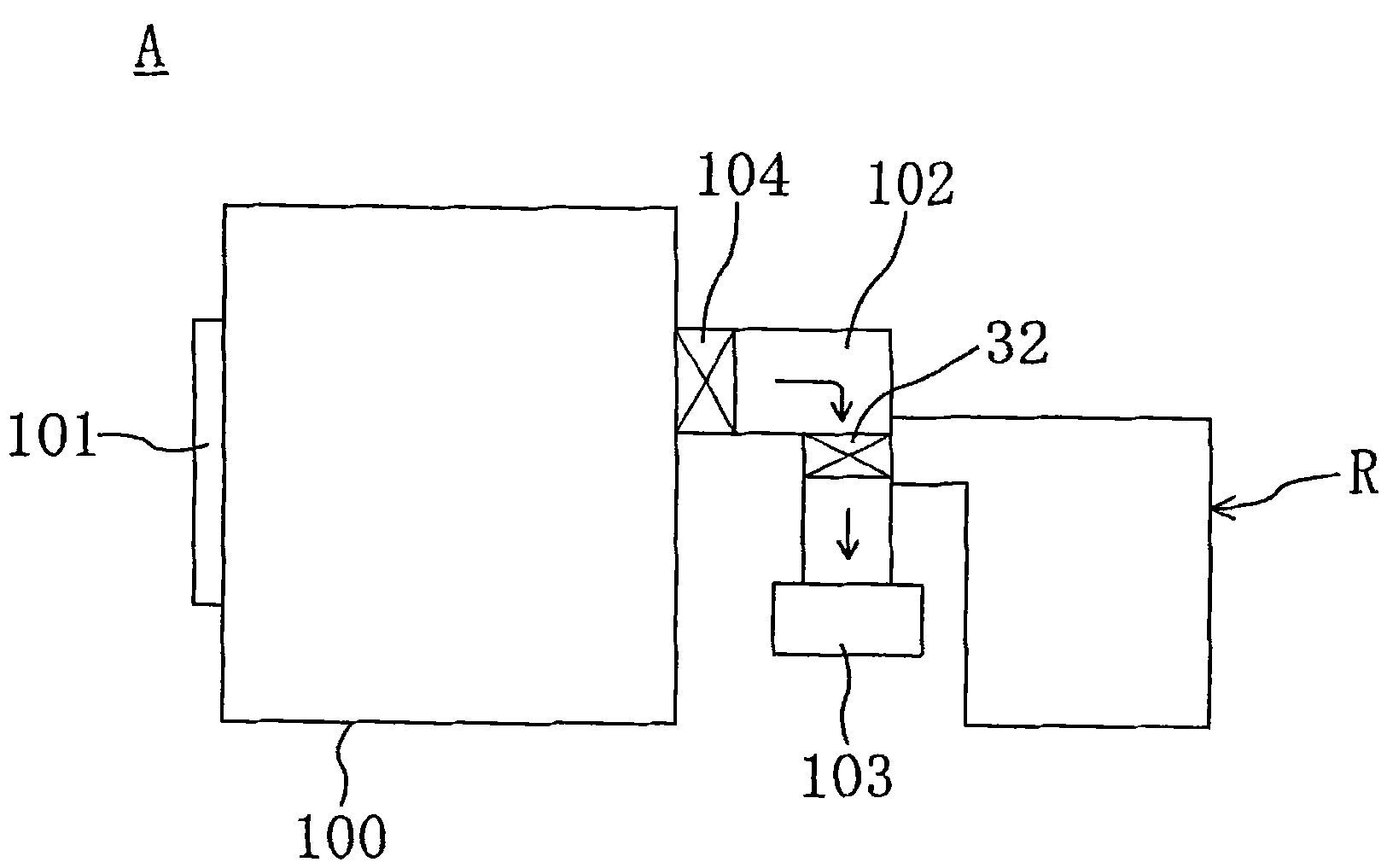

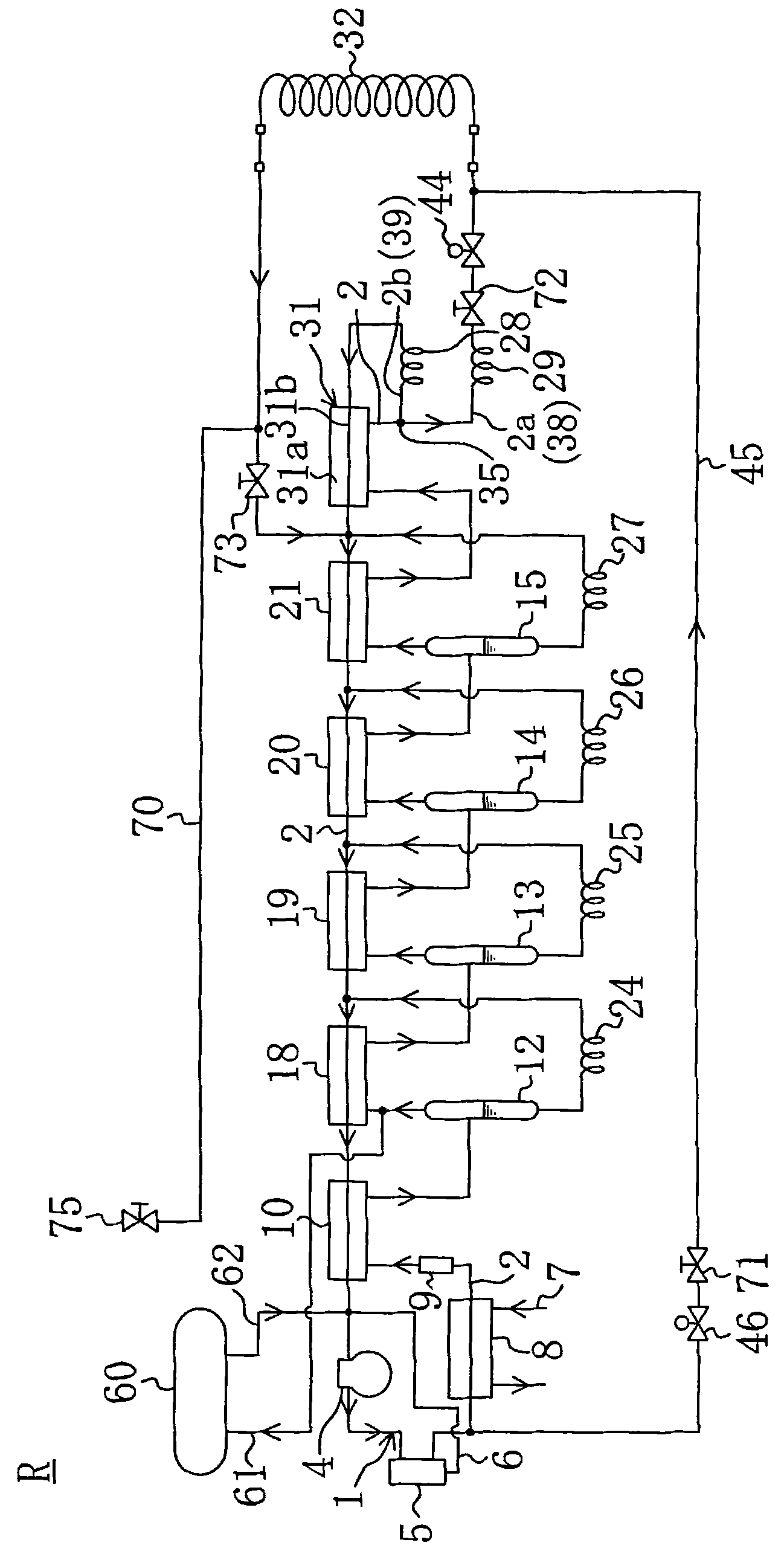

[0187] figure 1 , is a layout plane schematically showing the vacuum film forming apparatus A of the vacuum film forming apparatus according to the embodiment of the present invention. Figure 1 example. 100 is a vacuum container in which a substrate (not shown) (also referred to as a wafer) is deposited in a vacuum state. On the vacuum vessel 100, an entrance (not shown) opened and closed by the opening and closing door 101 is provided. With the opening and closing door 101 opened, the substrate to be filmed is sent into the vacuum vessel 100, or the film-forming substrate The substrate is taken out from the vacuum vessel 100. At the connecting part of the communication pipe 102 and the vacuum container 100, a switching slide valve 104 is provided to make the two communicate or cut off by opening and closing. When the opening and closing door 101 is closed and the slide valve 104 is opened, the vacuum pump 103 The operation brings the inside of the vacuum container 100 int...

Embodiment approach 2

[0215] Image 6 represents Embodiment 2 of the present invention (and, in each of the following embodiments, the same as Figure 1 to Figure 5 The same parts are marked with the same symbols and their detailed descriptions are omitted). In Embodiment 1, the sub-refrigerant circuit 39 is positioned lower than the main refrigerant circuit 38 , and more liquid refrigerant flows into the secondary side 31 b of the subcooler 31 than into the cryocoil 32 . In this regard, in this embodiment, when the sub-refrigerant circuit 39 and the main refrigerant circuit 38 are at the same height, the cross-sectional area of the sub-refrigerant circuit 39 is made larger than that of the main refrigerant circuit 38 .

[0216] That is, in this embodiment, different from Embodiment 1, the collective part 35a of the branch pipe 35, the main side branch pipe 35b and the main refrigerant pipe 2a connected thereto, the secondary side branch pipe 35c of the branch pipe 35 and the branch pipe 35c con...

Embodiment approach 3

[0223] Figure 7 and Figure 8 Embodiment 3 is shown, and is a combination of technical matters of Embodiment 1 and Embodiment 2. That is, in this embodiment, as in Embodiment 1 above, the main side branch pipe 35b and the secondary side branch pipe 35c of the branch pipe 35, the secondary side branch pipe 35c is arranged so as to be located at a position below the main side branch pipe 35b along an approximately vertical direction. The sub-side branch pipe 35c and the sub-refrigerant pipe 2b connected thereto are disposed in parallel vertically, and are arranged at a height lower than the main-side branch pipe 35b and the main refrigerant pipe 2a connected thereto. Meanwhile, in Embodiment 2, the main refrigerant pipe 2a connected to the main side branch pipe 35b of the branch pipe 35 uses a pipeline having a smaller diameter than the sub refrigerant pipe 2b connected to the sub side branch pipe 35c, and the cross section of the sub refrigerant circuit 39 The area is larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com