Isoworking medium and same working medium gas compression acting device

A technology for gas compression and work, applied in compressors, steam engine installations, irreversible cycle compressors, etc., can solve the problems of high cost and ineffective use of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

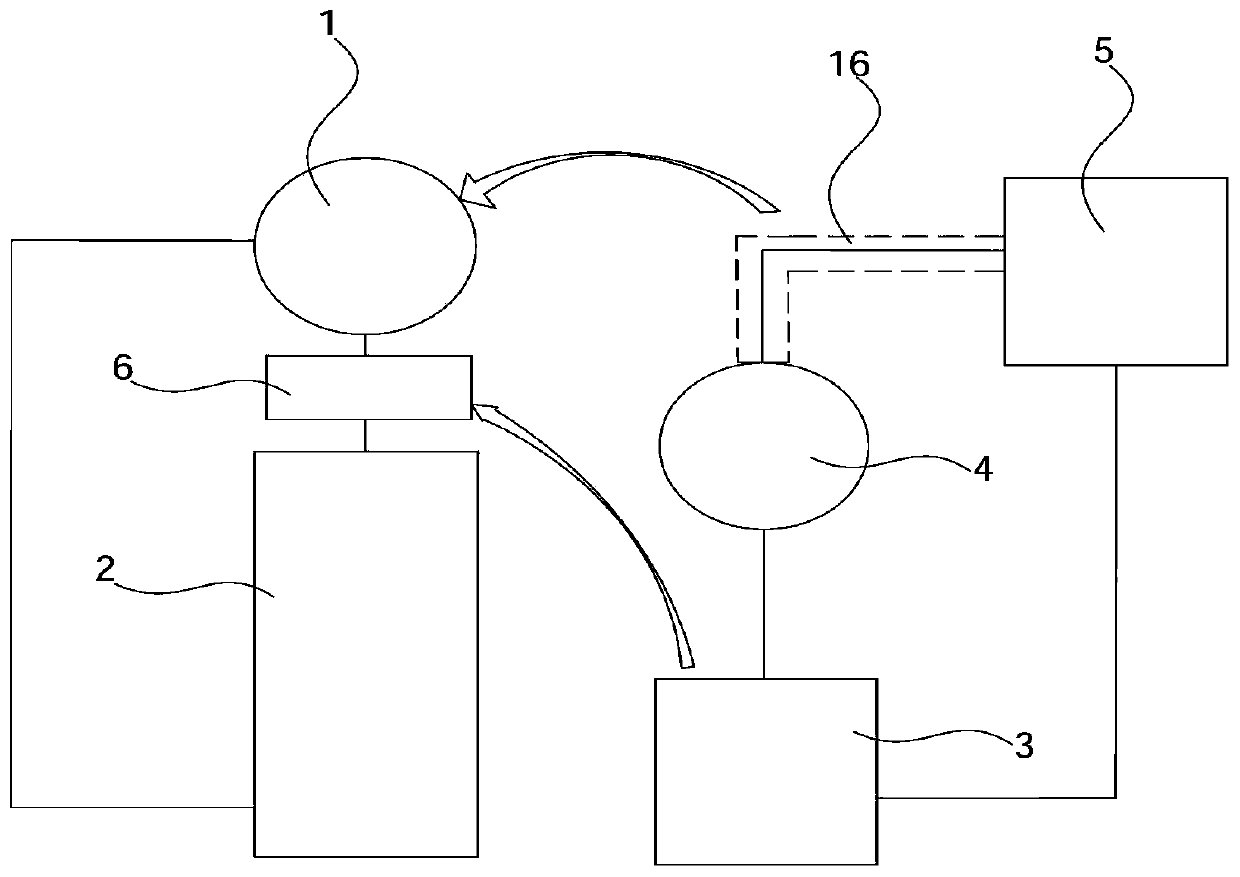

[0042] Embodiment 1, a kind of working device for compressing heterogeneous gas, such as figure 1 As shown, it includes a work system and a refrigeration system. The work system includes a first work device, a first condenser 6 connected to the outlet of the first work device, and a first evaporator 1 connected to the outlet of the first condenser 6. Refrigeration The system includes a compressor 4, a second condenser 5 connected to the outlet of the compressor 4, and a second evaporator 3 connected to the outlet of the second condenser 5, the outlet of the first evaporator 1 is connected to the inlet of the first work device The outlet of the second evaporator 3 is connected with the inlet of the compressor 4 , and a heating zone 16 is formed between the outlet of the compressor 4 and the second condenser 5 .

[0043] The work system is a carbon dioxide work system, and the refrigeration system is an R404A refrigeration system.

[0044] The work system can also use R23, R508...

Embodiment 2

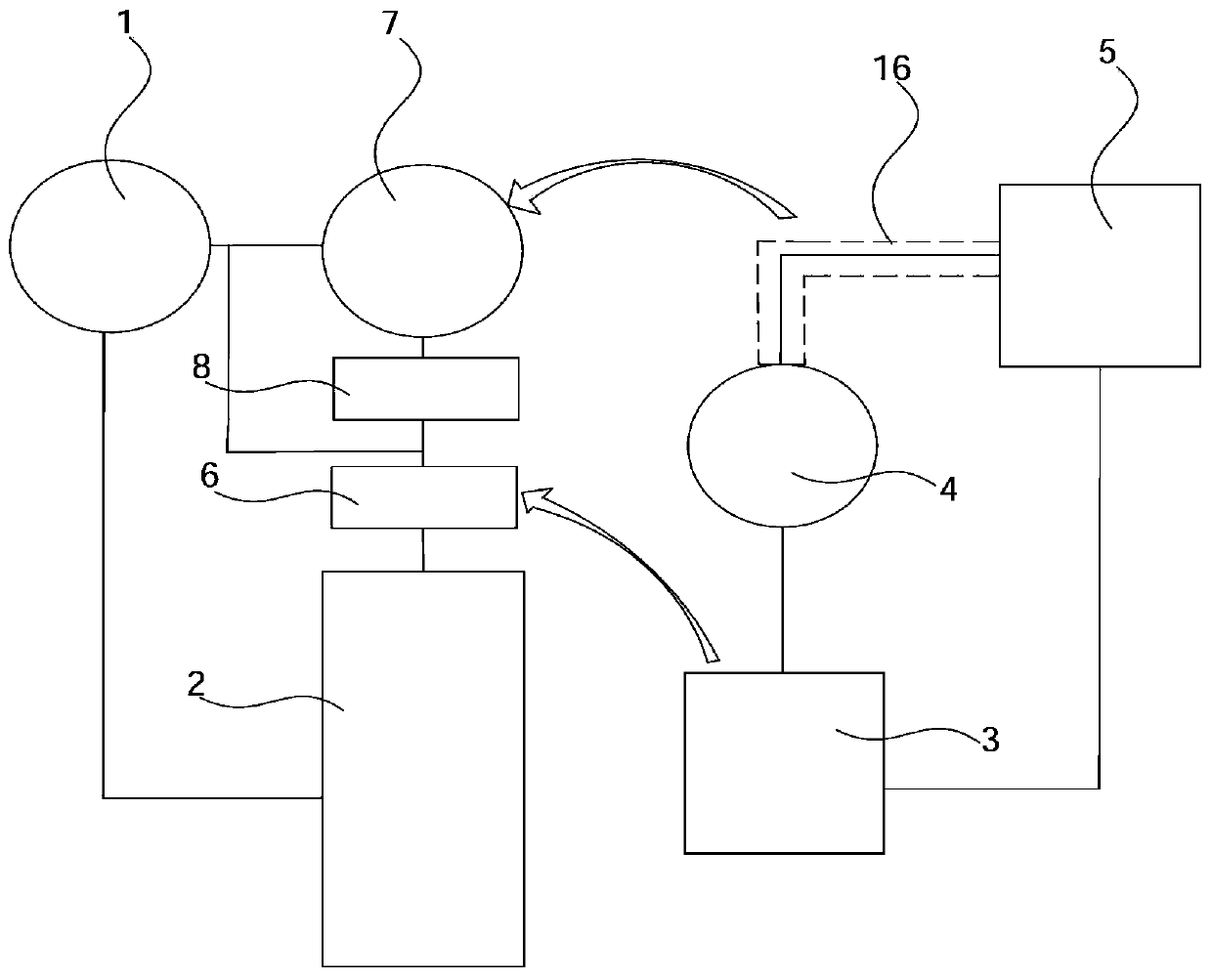

[0051] Embodiment 2, a heterogeneous gas compression work device, its structure is basically the same as that of Embodiment 1, the difference is that, as figure 2 As shown, the work system also includes a third evaporator 7 and a second work assembly 8, the first evaporator 1 is a low-pressure evaporator, the third evaporator 7 is a high-pressure evaporator, and the outlet of the third evaporator 7 It is connected with the second working component 8, the outlet of the second working component 8 is connected with the first working component 2, the first working component 2 is a low-voltage working component, and the second working component 8 is a high-voltage working component.

[0052] When the external cooling water demand reaches the set value, part of the liquid CO2 is sent from the first evaporator 1 to the third evaporator 7, where it is cooled by the external environment and the exhaust end of the compressor 4 connected to it. The heat of condensation of the system is ...

Embodiment 3

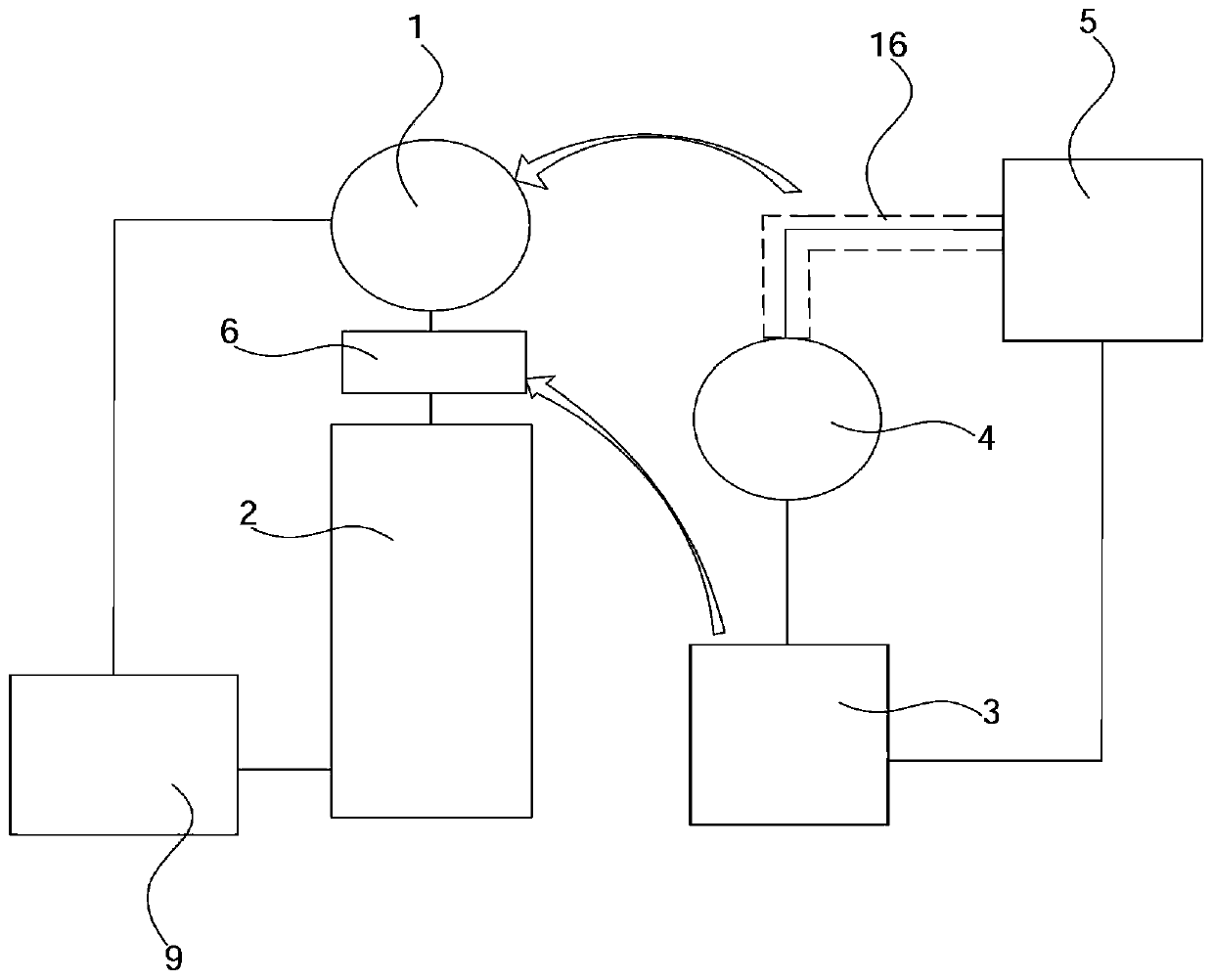

[0057] Embodiment three, a kind of homogeneous gas compression acting device, such as image 3 As shown, it includes a work system and a refrigeration system, and the work system and the refrigeration system use the same working fluid. The work system includes a first work assembly 2, a first condenser 6 connected to the outlet of the first work assembly 2, and a first condenser 6 connected liquefaction / desublimation working medium pool 9 and the first evaporator 1 connected to the outlet of the liquefaction / desublimation working medium pool 9, the outlet of the first evaporator 1 is connected to the first work assembly 2, and the refrigeration system includes a compressor Machine 4, the second condenser 5 that links to each other with the outlet of compressor 4 and the second evaporator 3 that links to each other with the outlet of second condenser 5, the outlet of second evaporator 3 links to each other with the inlet of compressor 4, working assembly It is electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com