Nano water ion cluster generator

An ion group and generator technology, applied in electrical components and other directions, can solve the problems of large device size, low refrigeration efficiency, and reduced release amount, and achieve the effects of increased bonding strength, increased release amount, and increased release amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

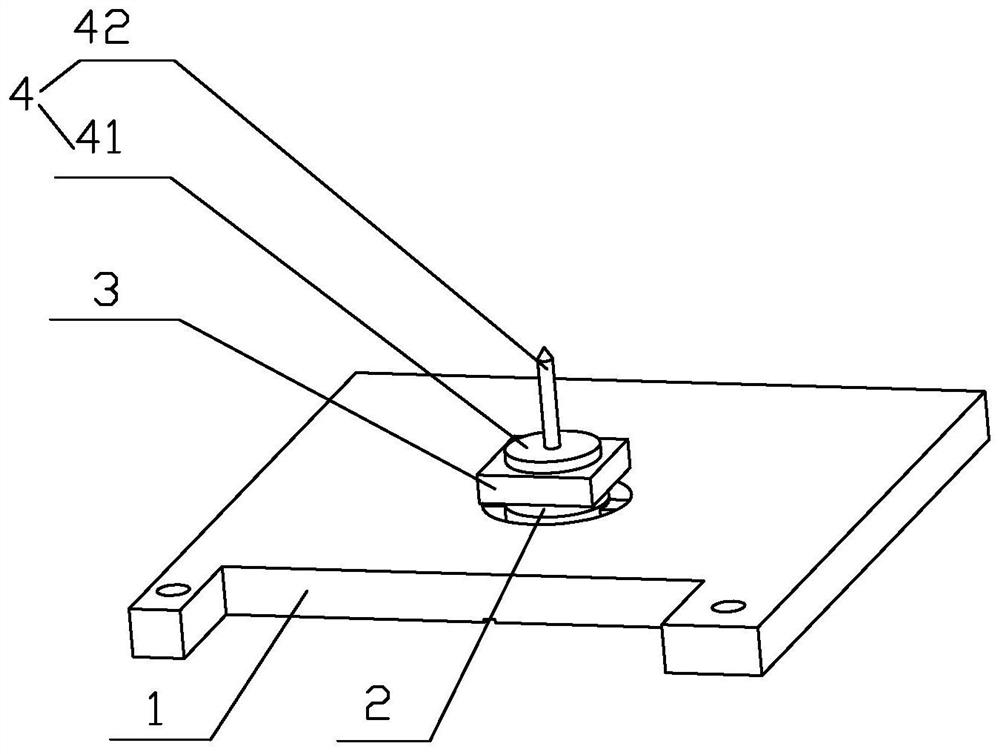

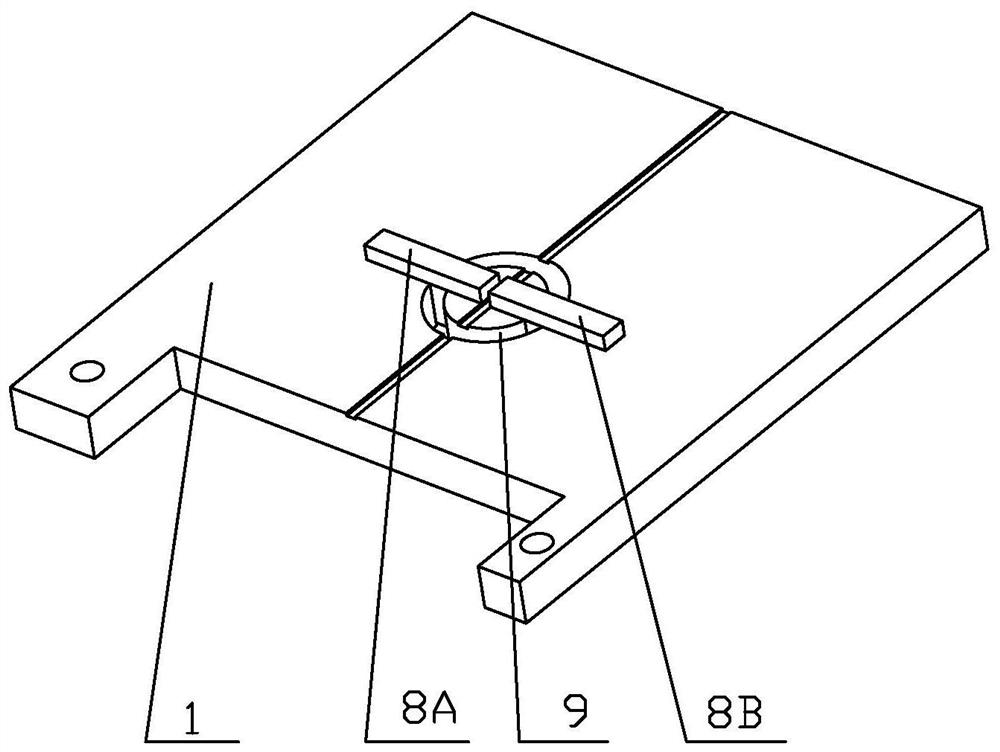

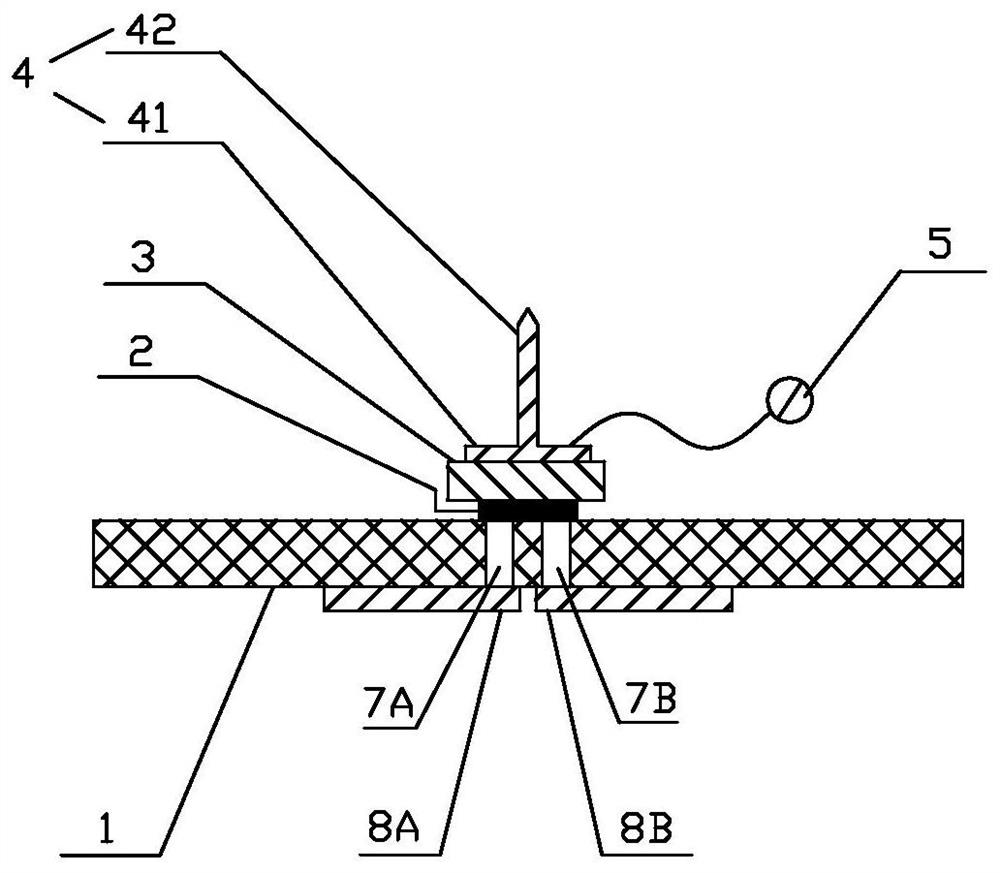

[0045] see Figure 1-3 , a nanometer water ion group generator according to an embodiment of the present invention, its main components include: a heat absorbing member 2, an N-type semiconductor crystal grain 7A, a P-type semiconductor crystal grain 7B, a heat sink 8, a blocking member 3, and a high-voltage power supply 5 and substrate 1.

[0046] As a further description of this embodiment, at least one pair of P / N type semiconductor crystal grains 7, the paired P / N type semiconductor crystal grains 7 are composed of P type semiconductor crystal grains 7B and N type semiconductor crystal grains 7A, the P One end of the / N-type semiconductor crystal grain 7 is a cooling end, which is used to obtain a temperature lower than the environment under the action of the thermoelectric effect, that is, cooling capacity; the other end of the P / N-type semiconductor crystal grain 7 is a heating end, which is used for In order to obtain the temperature higher than the environment under t...

Embodiment 2

[0067] The difference with embodiment 1 is: see Figure 4 , what this embodiment adopts is the ionizer II6, and the ionizer II6 is a water-absorbing material, and the water-absorbing material is made of a porous medium, and the porous medium is made of a fiber molded body, or a plurality of organic and / or inorganic fibers, so The water-absorbing material is used to absorb, accumulate or accumulate the cold, condensed water or moisture in the air 11 with high relative humidity, and at the same time form a multi-channel discharge path.

[0068] In this embodiment, the ionizer II6 is thermally coupled to the barrier 3 to absorb or accumulate cold, condensed water, or moisture in the air 11 with high relative humidity on the barrier 3, while reducing the The temperature of the ionization part II6 is to further form an air environment with high relative humidity in and around the ionization part II6.

[0069] The end of the ionizer II6 away from the barrier 33 is an ionization end...

Embodiment 3

[0072] The difference with embodiment 1 is: as Figure 5 As shown, there is a specified distance between the ionizer II6 and the barrier member 33, so that condensed water or high relative humidity air 11 is sufficiently formed between the ionizer II6 and the barrier member 3 to absorb , accumulating or accumulating condensed water on the barrier 3 or moisture in the air 11 with high relative humidity.

[0073] The high-voltage power supply 5 is electrically coupled to the ionizer II 6 through wires.

[0074] see Figure 8 , In addition, in order to support and fix the ionizing part II6, the ionizing part II6 is connected with a fixing part 12, and the fixing part 12 can be connected to the substrate 1 to achieve the effect of supporting and fixing the ionizing part II6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com