Preparation method and brazing method of aluminum alloy brazing composite board capable of being subjected to aging strengthening

A technology of aluminum alloy plate and composite plate, which is applied in the direction of metal rolling, etc., can solve the problems of poor material uniformity, large temperature difference between the head and tail of hot-rolled coils, and low strength, so as to achieve increased strength, high finish rolling temperature, and composite layer uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

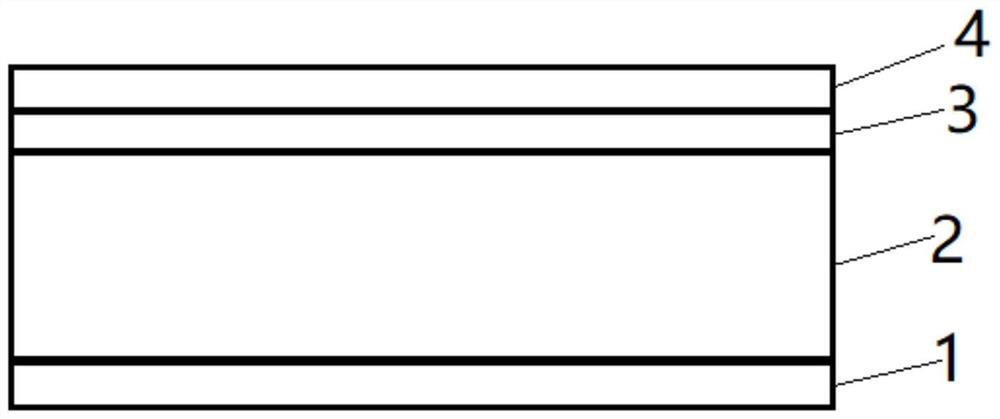

[0035] A method for preparing an age-strengthened aluminum alloy brazing composite plate, comprising the following steps:

[0036] S1. Lay up the first aluminum alloy plate, the second aluminum alloy plate, the third aluminum alloy plate and the fourth aluminum alloy plate in sequence, heat the prefabricated composite slab at 500°C for 3 hours, and pass through (1 +4) The hot rolling machine performs hot rough rolling to obtain a rough billet with a thickness of 30-35mm;

[0037] Among them, the first aluminum alloy plate and the third aluminum alloy plate are both made of 3-series aluminum alloy, and the fourth aluminum alloy plate is made of 4-series aluminum alloy; the composition of the second aluminum alloy plate is: 0.65wt% Si, 0.3wt%Fe, 0.25wt%Cu, 0.04wt%Mn, 1.1wt%Mg, 0.04wt%Zn, 0.04wt%Ti, the balance is Al and unavoidable impurities; the first aluminum alloy plate, the second aluminum alloy The thickness ratio of the plate, the third aluminum alloy plate and the fourt...

Embodiment 2

[0047] A method for preparing an age-strengthened aluminum alloy brazing composite plate, comprising the following steps:

[0048] S1. Lay up the first aluminum alloy plate, the second aluminum alloy plate, the third aluminum alloy plate and the fourth aluminum alloy plate in sequence, heat the prefabricated composite slab at 500°C for 2 hours, and pass through (1 +4) The hot rolling machine performs hot rough rolling to obtain a rough billet with a thickness of 32mm;

[0049] Among them, the first aluminum alloy plate and the third aluminum alloy plate are both made of 3-series aluminum alloy, and the fourth aluminum alloy plate is made of 4-series aluminum alloy; the composition of the second aluminum alloy plate is: 0.65wt% Si, 0.3wt%Fe, 0.25wt%Cu, 0.04wt%Mn, 1.1wt%Mg, 0.04wt%Zn, 0.04wt%Ti, the balance is Al and unavoidable impurities; the first aluminum alloy plate, the second aluminum alloy The thickness ratio of the plate, the third aluminum alloy plate and the fourth a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com