Stainless steel composite plate for petroleum and natural gas conveying pipeline and preparing method of stainless steel composite plate

A technology for oil and natural gas and transportation pipelines, which is applied in the field of stainless steel clad plates for oil and natural gas transportation pipes and its preparation, can solve the problems of low rolling power, cracks, differences in thermal expansion coefficients, etc. The effect of improving finish rolling temperature and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

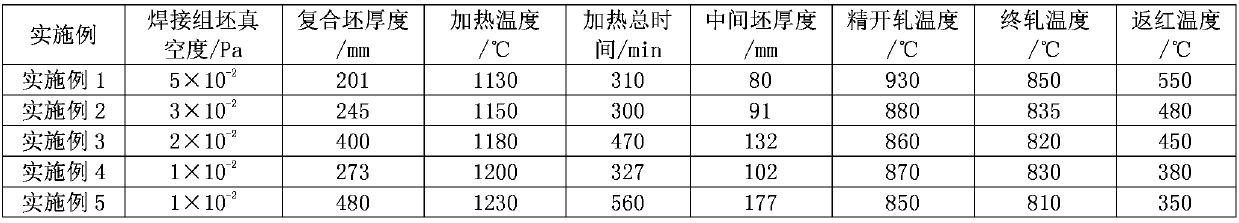

[0038] The preparation method of the stainless steel clad plate for the oil and gas transmission pipeline of Examples 1-5, the specific process parameters of each embodiment are shown in Table 3, and specifically include the following steps:

[0039] (1) Blank preparation: According to the variety and specification of the finished composite board, prepare the base material and cladding material blank, and polish the surface of the base material and cladding material blank to be compounded, remove the rust layer and oxide layer on the surface of the blank, and make the surface completely exposing fresh metal;

[0040](2) Release agent brushing: Apply release agent to the non-composite surface of the cladding material to ensure that the release agent is evenly brushed on the surface of the cladding material, and then dry the release agent;

[0041] (3) Composite billet preparation: Spot-weld the seal on the periphery of one of the base materials to be compounded. The height of t...

Embodiment 1

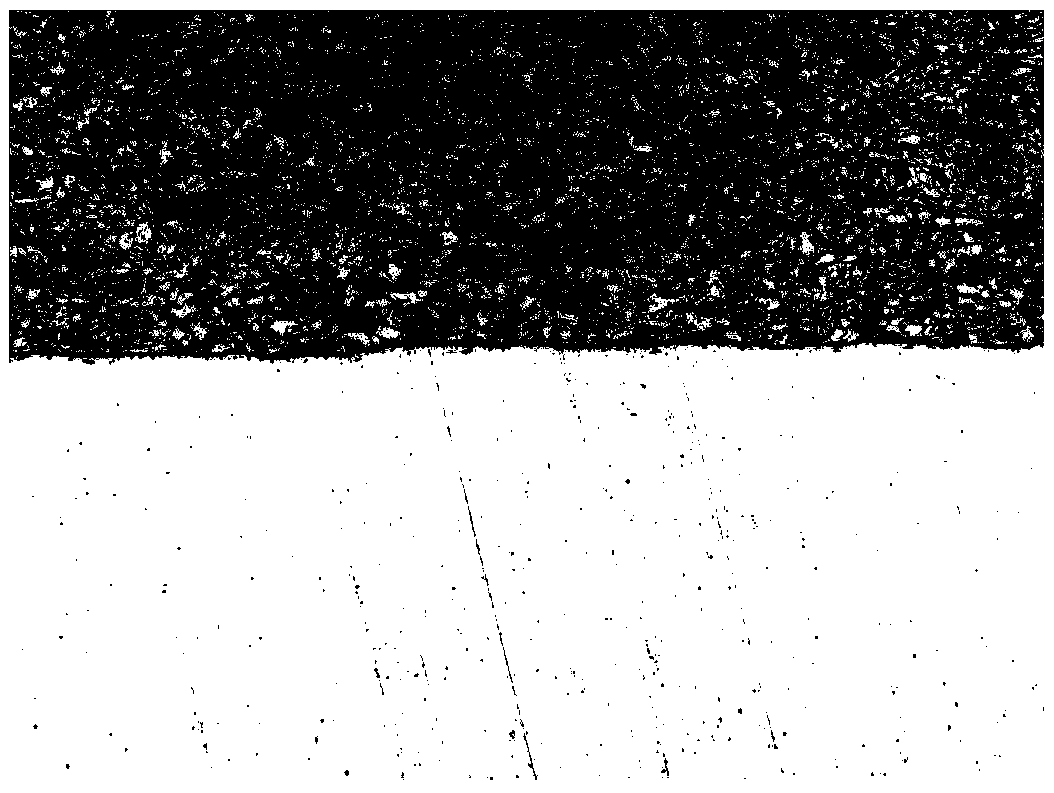

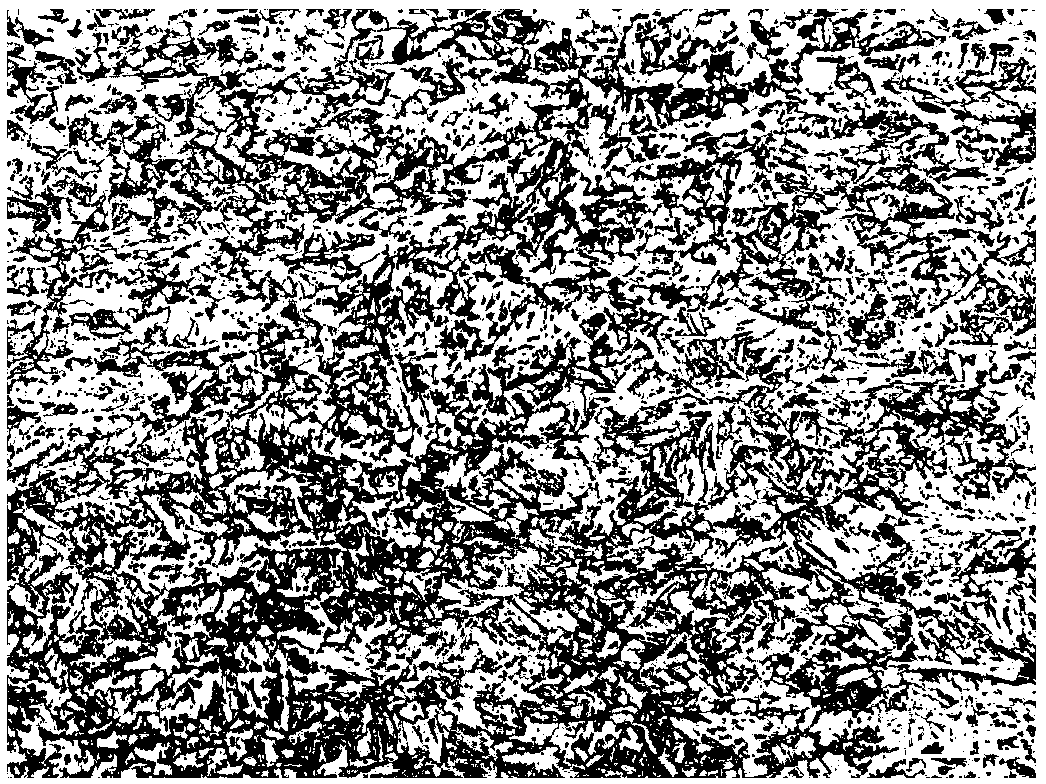

[0050] The structural and performance parameters of the composite boards in Examples 1-5 are specifically shown in Table 4. The composite boards have excellent tensile, impact, bending, shear strength and intergranular corrosion resistance. figure 1 and figure 2 It is a photo of the composite interface microstructure of the composite plate in Example 1 and the microstructure of the base material. It can be seen from the figure that the composite plate achieves good metallurgical bonding, and the structure of the base material is bainite + proeutectoid ferrite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com