Method and nozzle arrangement for variable-width lubrication of rolling nip of rolling stand

A rolling mill and nozzle technology, applied in the field of lubricating rolls, can solve problems such as the weakening of sufficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

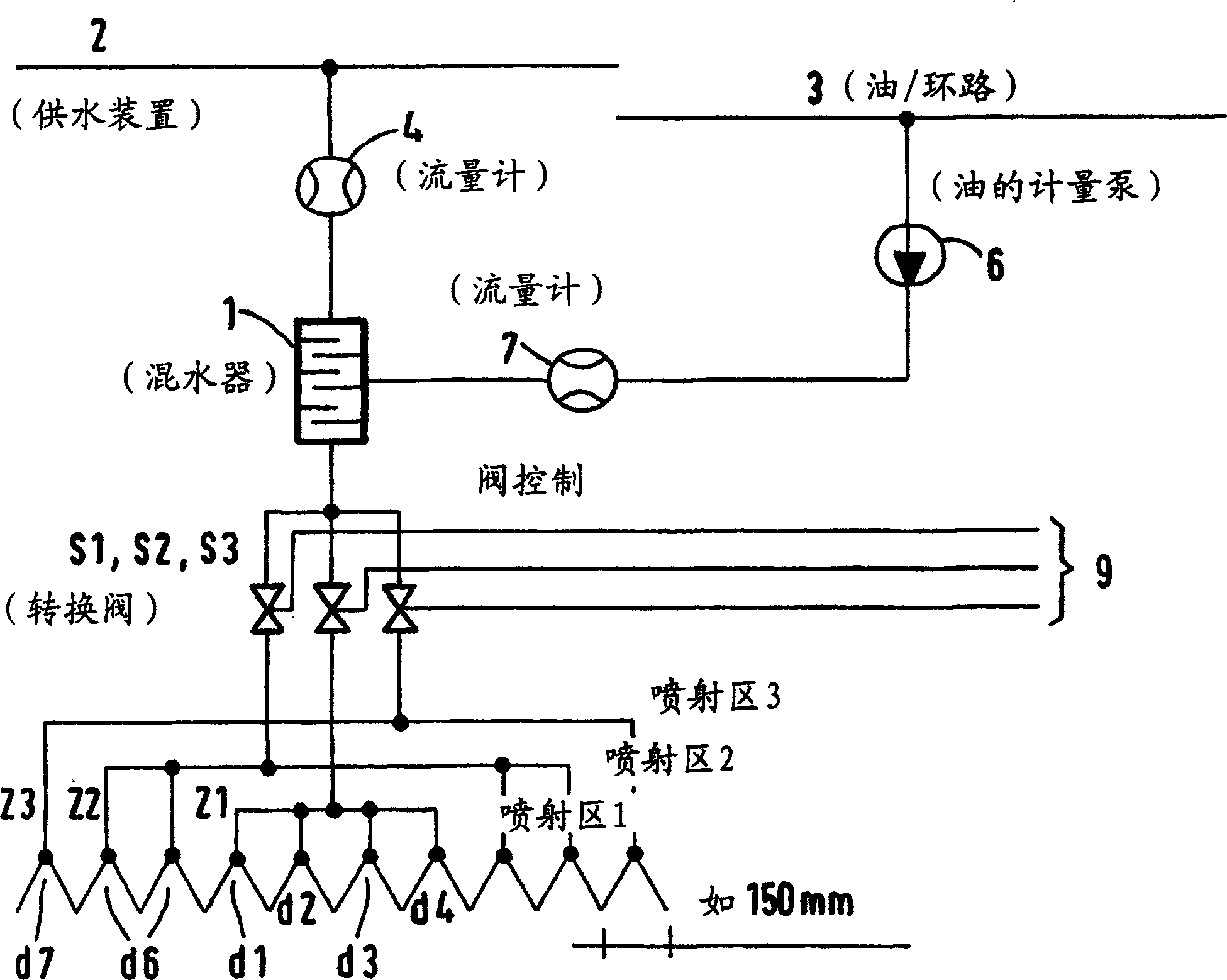

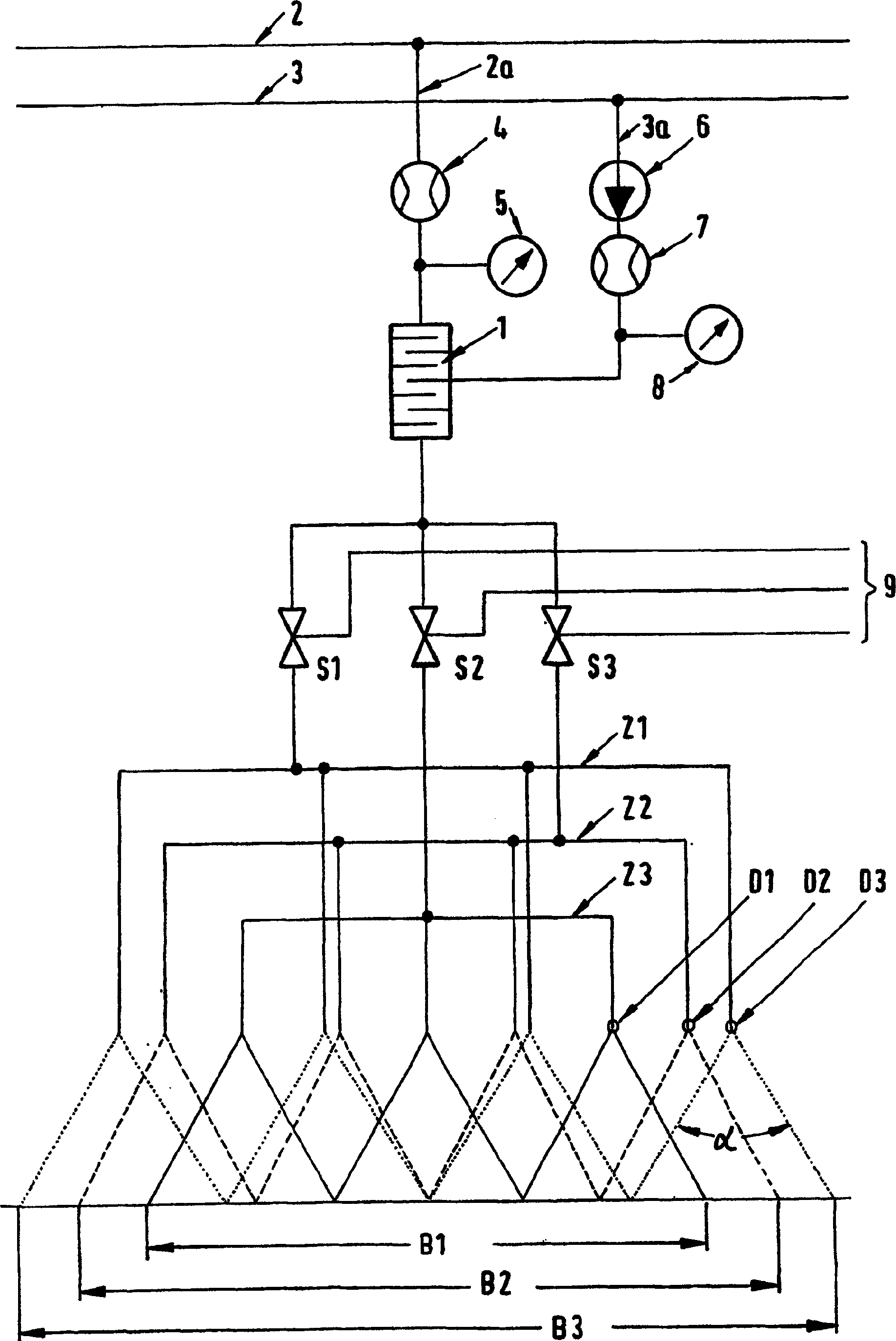

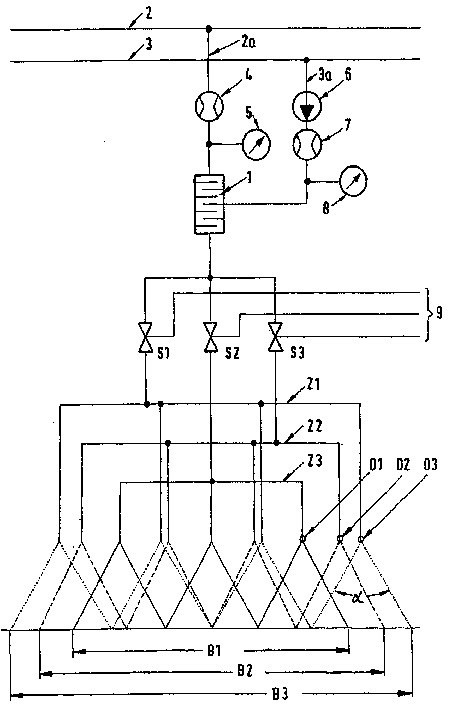

[0029] figure 1 A device for lubricating rolls or roll gaps with adjustable width in a rolling mill (not shown) according to the prior art is shown with a water supply 2 and an oil line 3 . Both substances are supplied to the device under pressure. Reference numerals 4 and 7 denote flow meters for water and oil, respectively. Mark 6 represents a metering pump for dispensing a small amount of emulsified oil. Reference 1 denotes a water mixer known per se, in which water and oil are intimately mixed with each other. S1-S3 designate three switching valves which are switched individually, for example by means of compressed air 9 . Each switching valve S1-S3 is connected to an injection zone Z1-Z3 respectively.

[0030] In the example shown, spray zone Z1 is equipped with four nozzles d1-d4. Spray zone Z2 is equipped with four switchable nozzles d6, while spray zone Z3 is also equipped with two further nozzles d7.

[0031] if now as figure 1 The spray zone Z1 shown is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com