Ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and method

A technology of process equipment and elongation rate, used in metal processing equipment, workpiece lubrication devices, workpiece cleaning devices, etc., can solve the problems of high production dust, environmental pollution, low elongation rate of steel plates, etc. The effect of surface and product comprehensive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

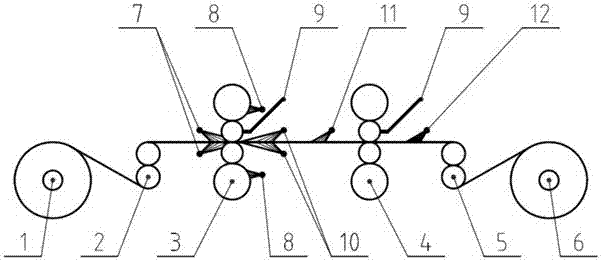

[0036] In order to overcome the problems of low elongation, low hardness, many surface defects, and environmental pollution caused by production dust in the existing ultra-thin tinplate raw plate production process, such as figure 1 As shown, this embodiment provides a wet leveling process equipment for ultra-thin tin-plated raw plate with large elongation, including uncoiler 1, entrance tension roller 2, No.1 rolling mill 3, No.2 rolling mill 4, and exit tension roll arranged in sequence. Roller 5 and coiler 6, the No. 1 rolling mill 3 is equipped with a leveling liquid system 7 at the entrance end, which is characterized in that: the leveling liquid system 7 uses an emulsion with a concentration of 0.5% to 1.5% as the leveling liquid, No. The exit ends of 1 rolling mill 3 and No. 2 rolling mill 4 are respectively provided with anti-splash devices 9 installed on the stands.

[0037] The working process of ultra-thin tin-plated raw plate large elongation wet leveling process e...

Embodiment 2

[0043]On the basis of Example 1, such as figure 1 As shown, the two anti-splash devices 9 are located on the sides of the work rolls on No.1 rolling mill 3 and No.2 rolling mill 4. The anti-splash devices 9 are welded by two steel plates, one of which is set horizontally, and the other The steel plates are arranged obliquely, and the angle between the two steel plates forms an obtuse angle with the opening facing upwards and is fixedly installed on the frame.

[0044] The anti-splash device 9 is installed on the upper side of the strip steel at the exit of No. 1 rolling mill 3 and No. 2 rolling mill 4. It is used to prevent the leveling liquid splashed by the rolling roll from falling on the steel plate. The area from the centerline of the upper work roll to the centerline of the lower work roll at the exit of No.1 rolling mill 3 and No.2 rolling mill 4 is shown.

Embodiment 3

[0046] On the basis of Example 1, the ultra-thin tinplate raw plate large elongation wet leveling process equipment also includes an lye washing device 8, the lye washing device 8 includes an lye tank, a centrifugal pump and a heat conduction oil heater, and the heat conduction oil heater The circulation pipeline is connected with the lye tank, the lye tank is connected with the centrifugal pump, and the centrifugal pump is connected with the spray beam, and the spray nozzle on the spray beam is directly facing the upper and lower surfaces of the steel strip at the exit end of No.1 rolling mill 3.

[0047] The lye washing device 8 is used to clean the residual emulsion on the surface of the flat rolled steel strip, and is mainly composed of an lye tank, a centrifugal pump and a heat transfer oil heater. The lye washing device 8 is installed on the outside of the No. 1 rolling mill 3 outlet facing the upper and lower back-up rolls, and is used for real-time washing of the residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com