Four-pass rolling method for aluminum foil with thickness being 0.005 mm

A technology of aluminum foil and foil rolling, which is applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of not being able to obtain ultra-thin aluminum foil products, and achieve the effects of improving efficiency, reducing fuel consumption, and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

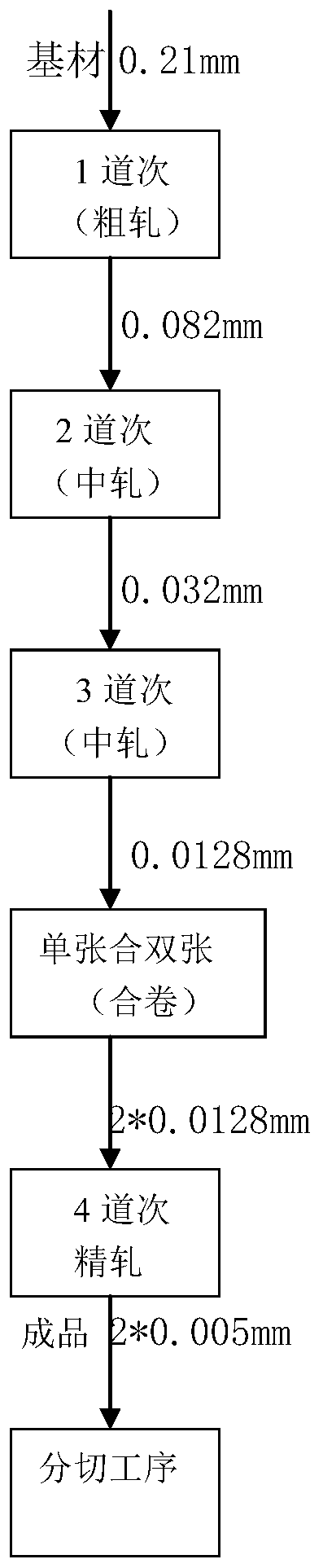

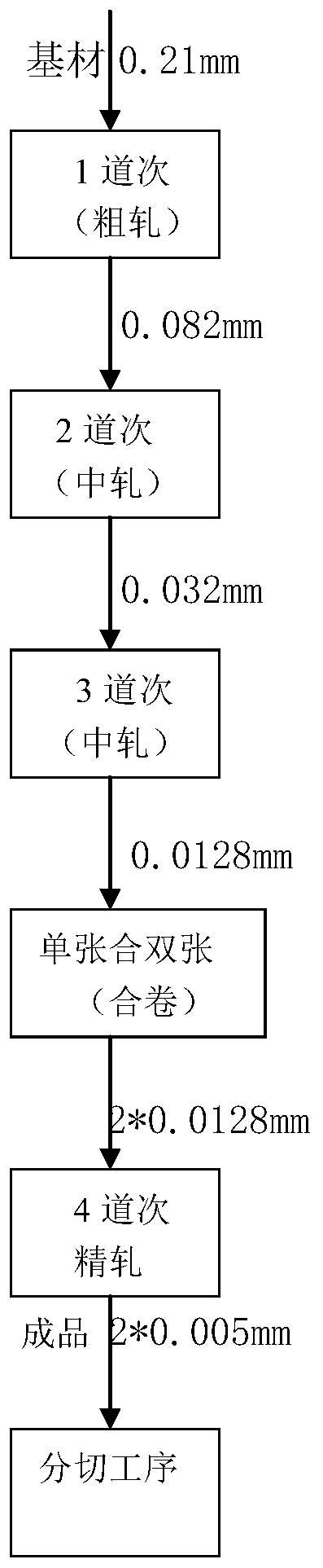

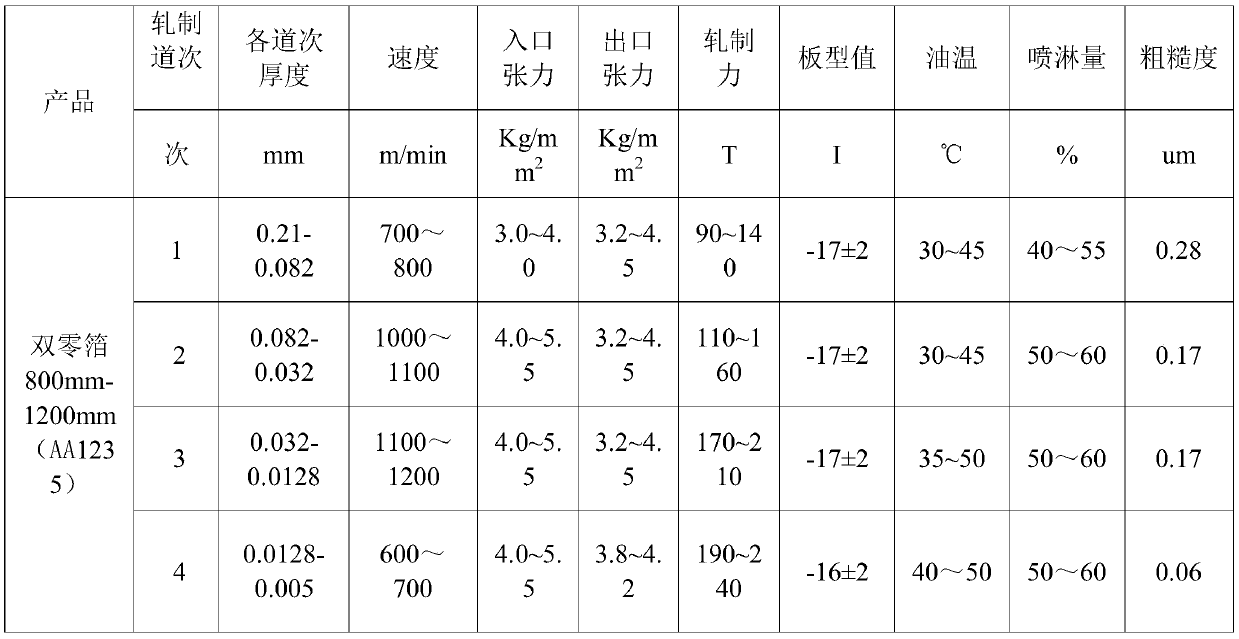

[0033] Foil rolling 4-pass foil rolling preparation process of the present invention: 0.21mm-0.082mm-0.032mm-0.0128mm-coil 2*0.0128*2*0.005mm.

[0034] The above average reduction in each pass is about 60%, the foil rolling speed is 700-800m / min for the first pass, 1000-1100m / min for the second pass, 1100-1200m / min for the third pass, and 1100-1200m / min for the third pass. The four passes are 600-700m / min. The thickness of the aluminum foil at the first entrance is 0.21mm, and the alloy grade is AA1235.

[0035] The 4-pass rolling method of 0.005mm thick aluminum foil comprises the following steps:

[0036] 1), base material

[0037] A billet with a thickness of 0.21m is used, and the alloy is AA1235;

[0038] 2), the first pass of foil rolling

[0039] The base material with a thickness of 0.21mm enters the 4-roller rolling of the rough rolling mill (it is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com