Improved automatic lubricant cleaning device for hub forging die

A lubricant and mold technology, which is applied in the field of graphite lubricant cleaning devices, can solve the problems of high temperature of forging molds, difficult cleaning, and high labor intensity of workers, and achieve the effects of reducing production intensity, improving labor efficiency, and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

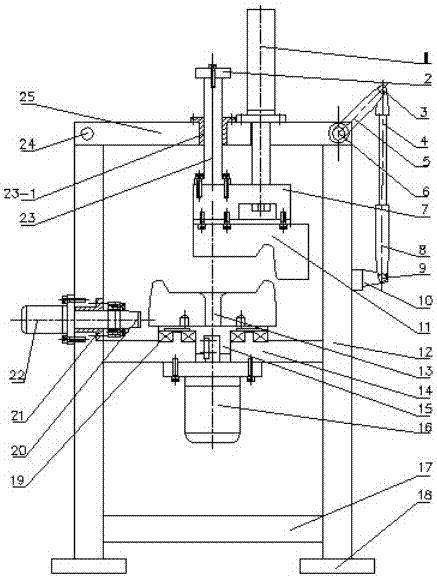

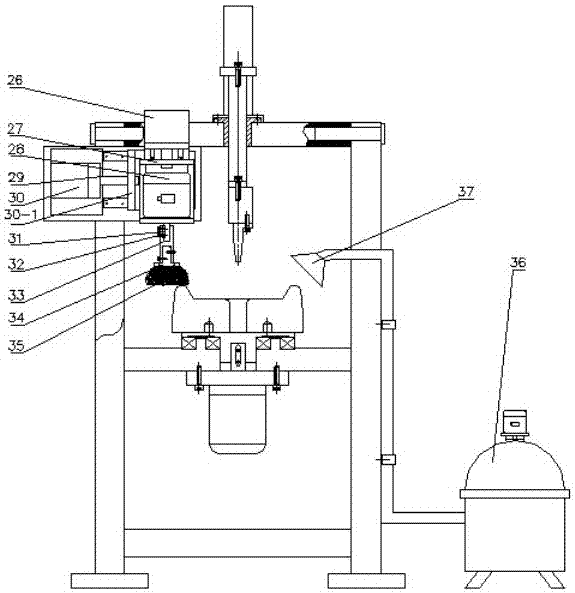

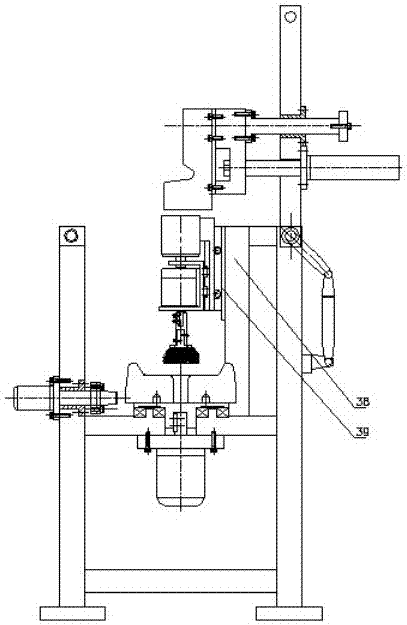

[0017] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Improved automatic lubricant cleaning device for hub forging die. It consists of lifting hydraulic cylinder 1, limit block 2, hinge A3, hydraulic piston rod 4, fixed connecting rod 5, hinge shaft 6, connecting plate 7, hydraulic cylinder 8, hinge B9, hydraulic cylinder fixing seat 10, lubricant cleaning scraper 11. Main frame 12, bracket beam 14, mold support tray 15, servo motor 16, foundation beam 17, base 18, rolling bearing 19, left lubricant cleaning scraper 20, bolt A21, left hydraulic cylinder assembly 22, guide post 23 , guide sleeve 23-1, plug-in lock pin 24, lift hydraulic cylinder support beam 25, brush lift hydraulic cylinder 26, lift bracket 27, brush servo motor 28, linear guide rail 29, translation hydraulic cylinder 30, connection key 21, bolt B32, connecting sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com