Method for lubricating and cooling rollers and metal strips on rolling in particular on cold rolling of metal strips

A technology of metal strips and counter rolls, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

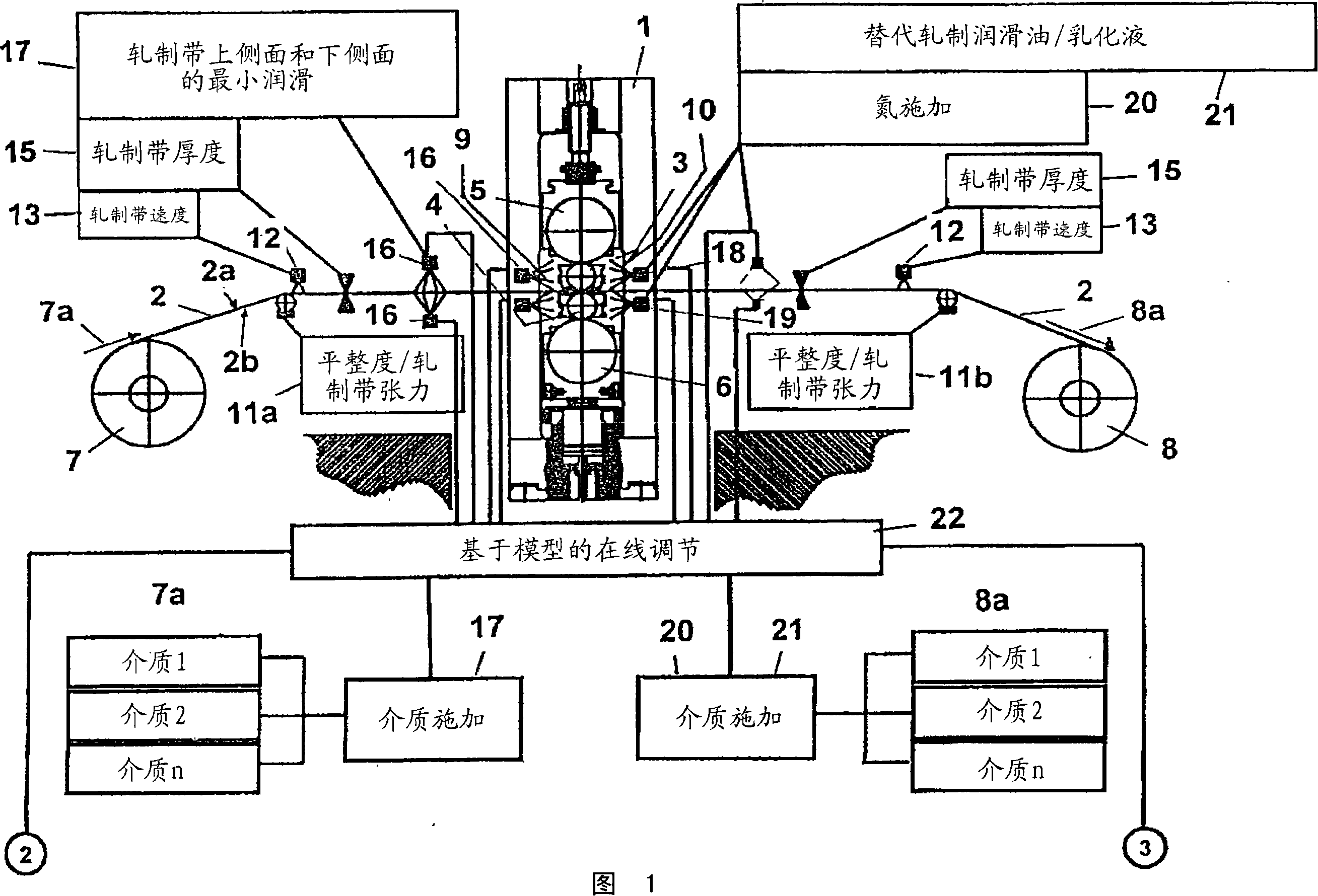

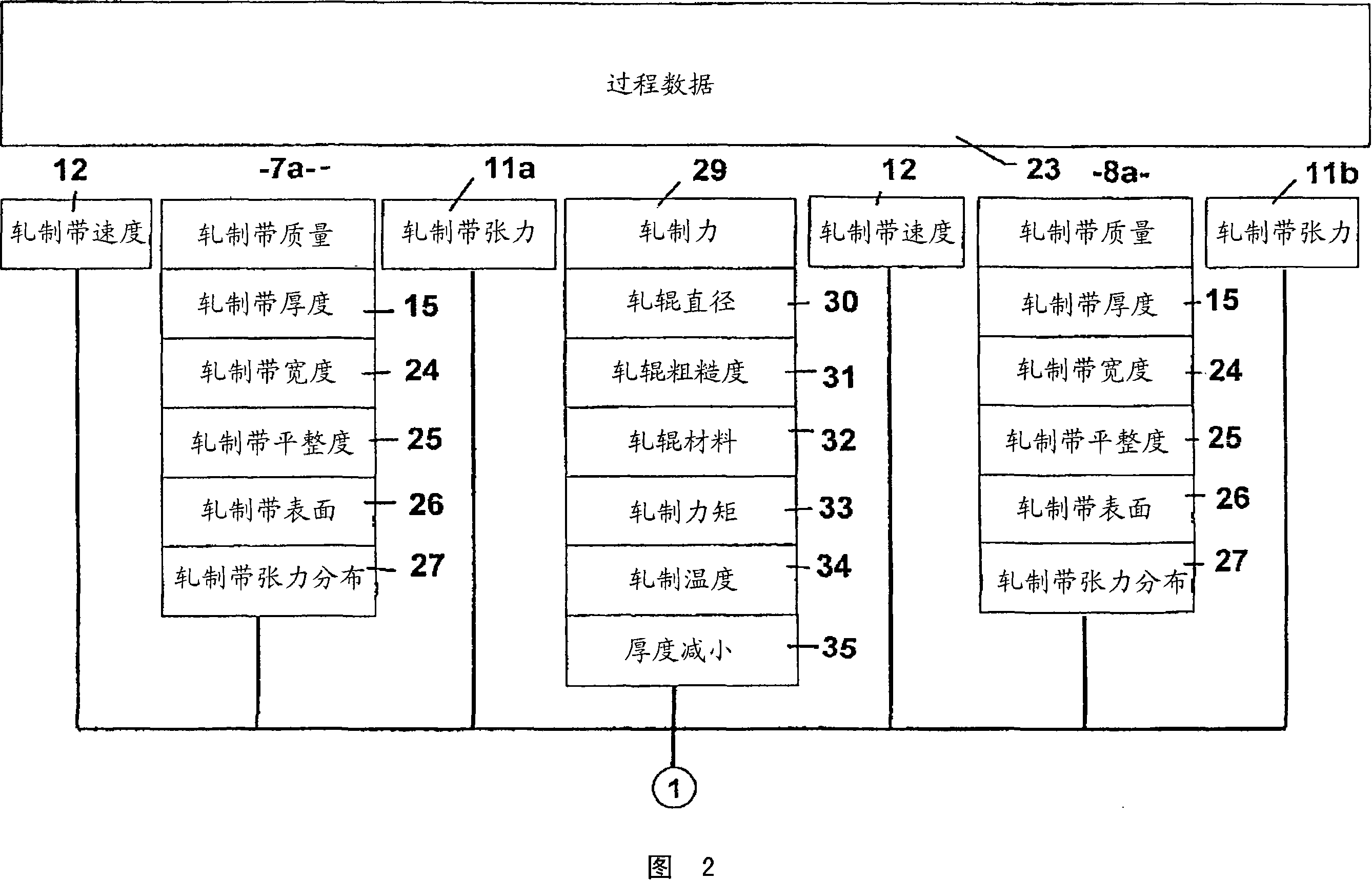

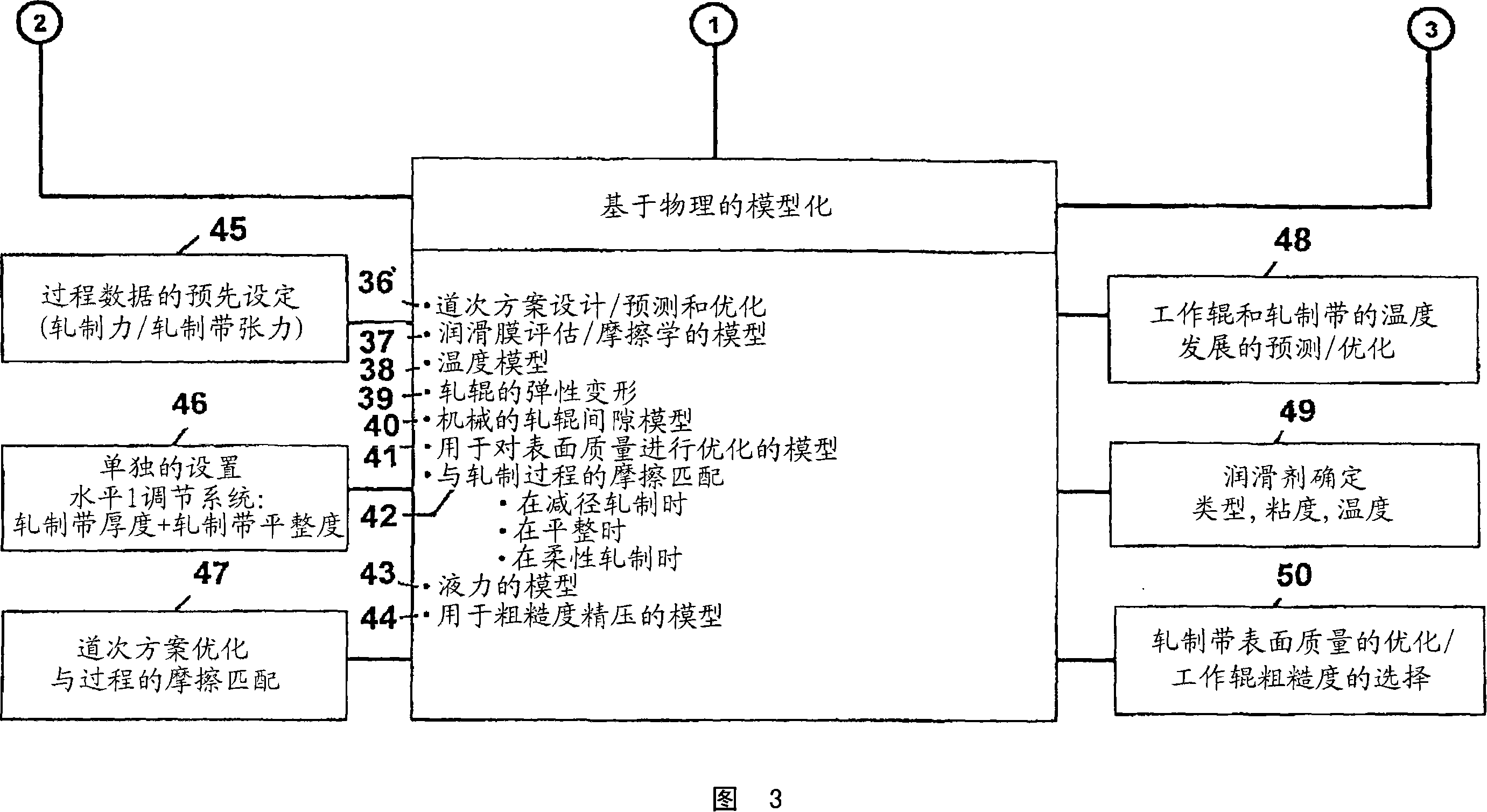

[0051] A rolling stand 1 ( FIG. 1 ) for a metal strip 2 (for example made of heavy or light metals of different alloys) has upper and lower work rolls 3 , 4 which are supported on backup rolls 5 in chocks , Between 6. Figure 1 shows a four-high rolling mill stand. The described application can be applied to all types of rolling stands, such as six-high rolling stands, twenty-high rolling stands, two-high rolling stands and the like. The metal strip 2 is guided from the uncoiling station 7 on the inlet side 7a to the winding station 8 on the outlet side 8a. On the inlet side 7a, a pure lubricant 9 is applied as a chemical component by spraying, and on the outlet side 8a, a coolant 10 is applied by spraying. The lubricant 9 and the coolant 10 consist of lubricating, scrubbing and inertizing materials or gases and also form combinations of these materials or gases and are fed to the lower side 2a of the rolling strip and to the rolling mill. Take it on side 2b. Emulsions with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com