Method for producing ultra-thin metal lithium strip

A technology of ultra-thin metals and production methods, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of limited space for specific capacity development, achieve the effect of improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

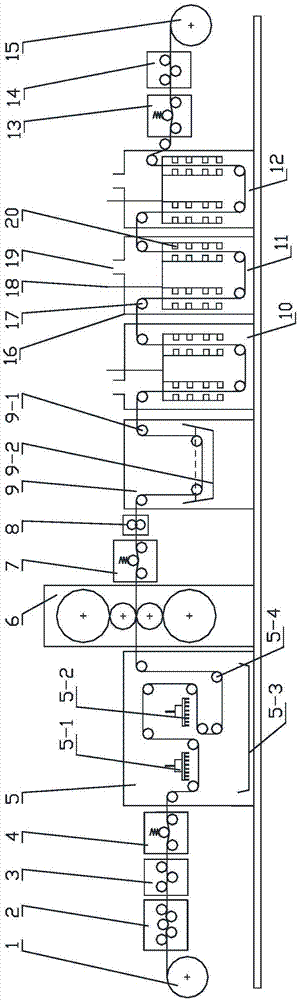

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see figure 1 , a kind of production method of ultra-thin metal lithium strip, adopts the following steps: 1) coating lubricant on the base material surface, the base material surface is processed, to avoid sticking with roll when rolling. The thickness of the substrate may be 0.1 mm.

[0019] 2) Rolling.

[0020] 3) trimming.

[0021] 4) Clean the oil on the surface of the lithium belt.

[0022] 5) Air-dry the lithium strip and remove surface impurities to obtain an ultra-thin metal lithium strip.

[0023] The above-mentioned production method has relatively strict requirements on the relative humidity of the environment, preferably below 1%. After rolling, the lithium strip is cleaned and dried to ensure that the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com