Ultrathin metal lithium foil production device and method

A technology of ultra-thin metal and production equipment, which is applied in the direction of electrode manufacturing, electrical components, battery electrodes, etc., can solve the problems of limited space for specific capacity development, achieve the effect of improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

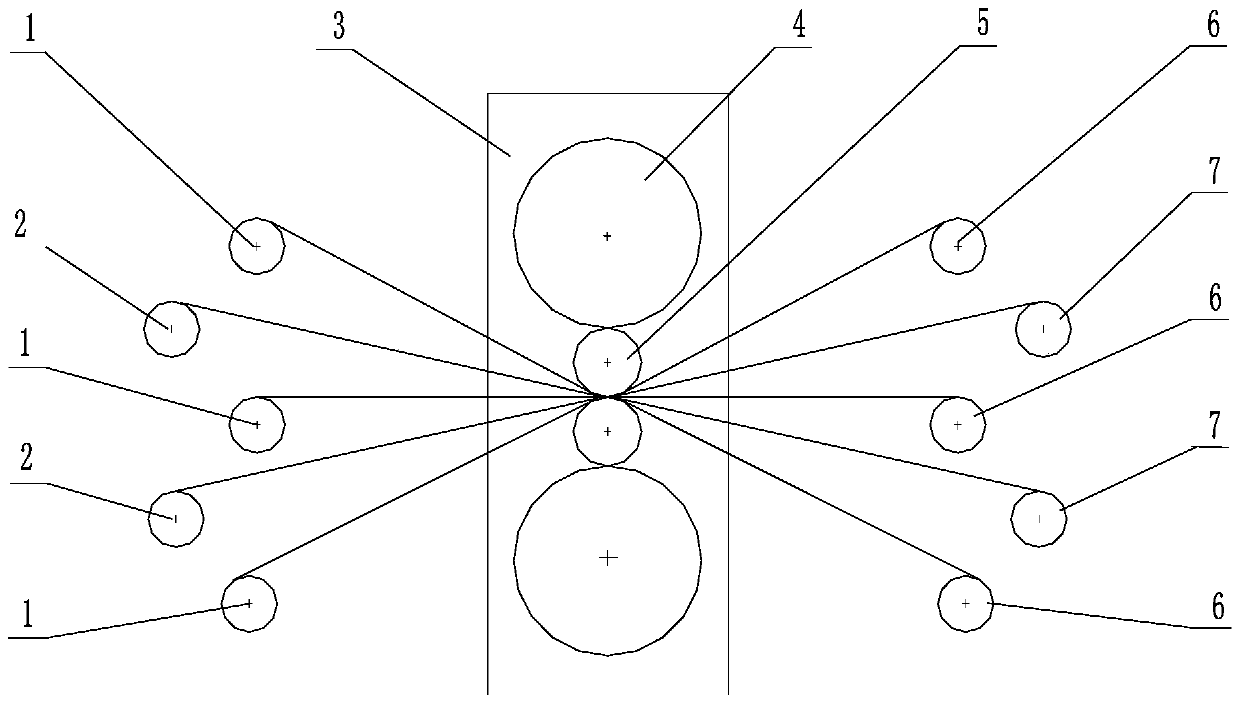

[0014] see figure 1 , an ultra-thin metal lithium foil production device, comprising a rolling mill 3, at least two lithium foil strip unwinding devices 2 are arranged in front of the rolling mill 3, above and below each lithium foil strip unwinding device 2 Each is provided with a lining film strip unwinding device 1; at least two lithium foil strip winding devices 7 are arranged behind the rolling mill 3, and above and below each lithium foil strip winding device 7 are respectively provided A liner tape take-up device 6 .

[0015] In this embodiment, an unwinding tension control device I is provided behind the lithium foil tape unwinding device 2 , and a winding tension control device I is provided in front of the lithium foil tape rewinding device 7 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com