Apparatus and method for rolling metal

A metal and metal sheet technology, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems of excessive debris, reducing the surface finish of the sheet, and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

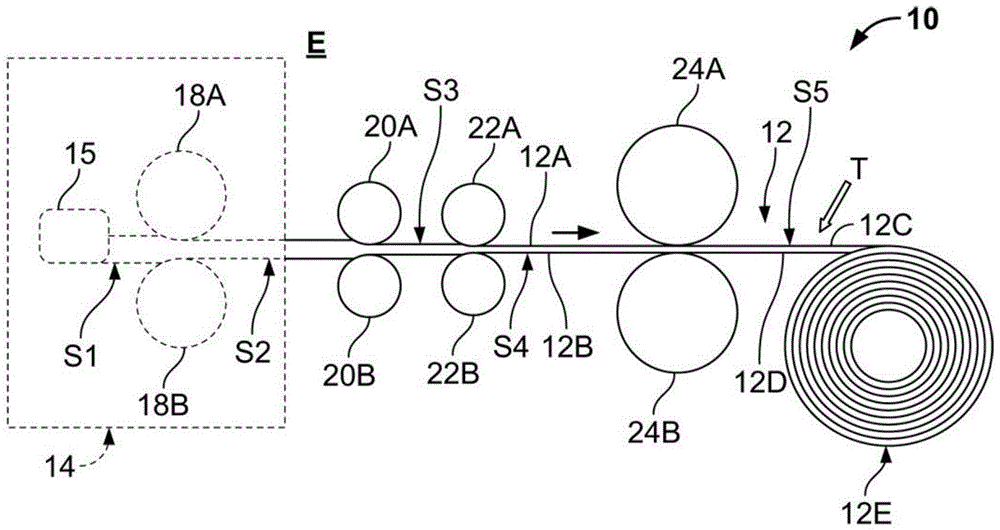

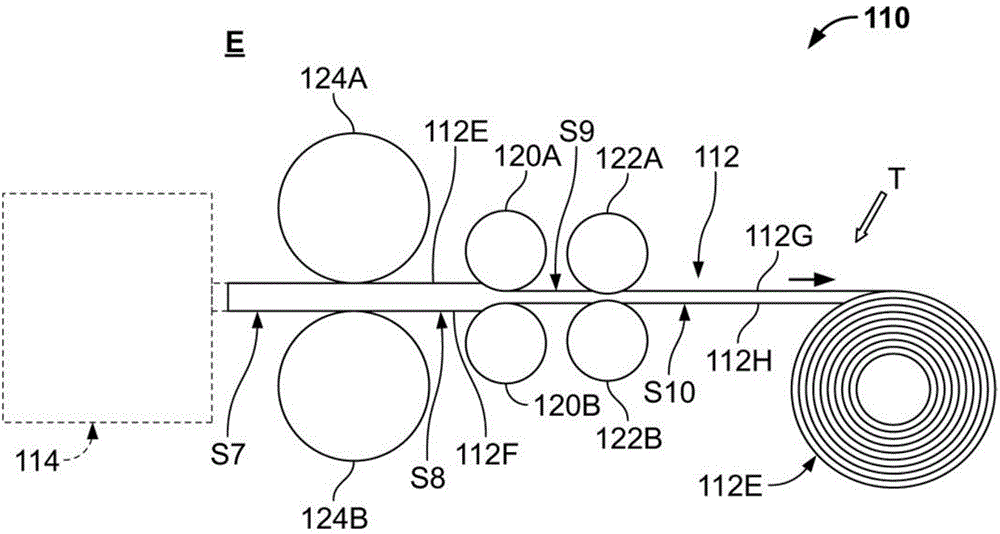

Embodiment Construction

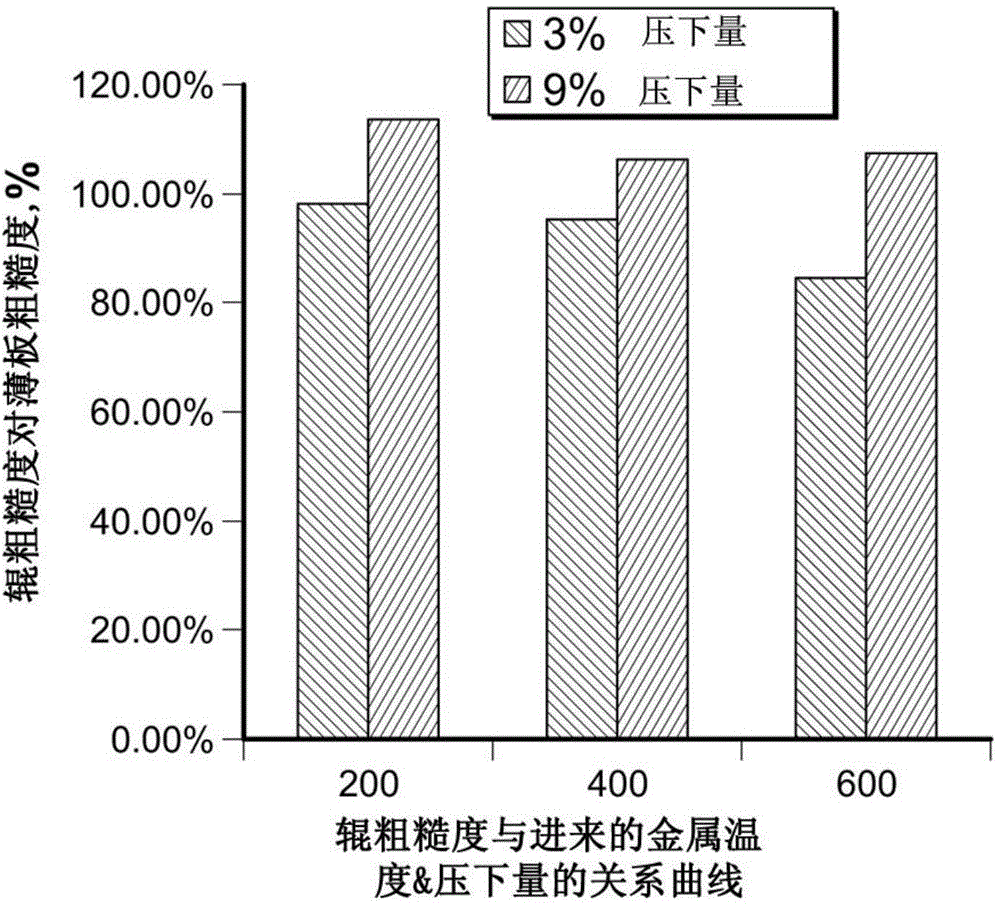

[0082] Aspects of the present disclosure include the recognition that surface texturing occurs when the sheet to be textured is heated, for example, between 250-970°F to reduce rolling pressure and increase transfer; texturing can It is used to repair or improve damage to the surface and subcutaneous surface of the sheet or caused by upstream processes (such as cracks, scratches, cracks and dents adversely affected by conventional cold texturing), which results in Improvement of surface quality by eliminating surface features or patterns incoming to a casting or rolling process; texturing can be applied as an intermediate step in rolling, followed by subsequent rolling passes in subsequent stages Improves and facilitates subsequent steps in the rolling process, such as compression rolling by heating or cooling rolls; the "rough" texture imparted by textured rolls with a "rough" surface can be used to repair surface defects, preparing for further Processed sheet and production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com