Laser engraving processing method and device for ultra-soft printing roller

A technology of laser engraving and processing method, which is applied in printing, printing plate preparation, etc., can solve the problems of rough printing pattern, low definition, poor screen printing quality, etc., and achieve clear printing effect, controllable volume and exquisite pattern Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

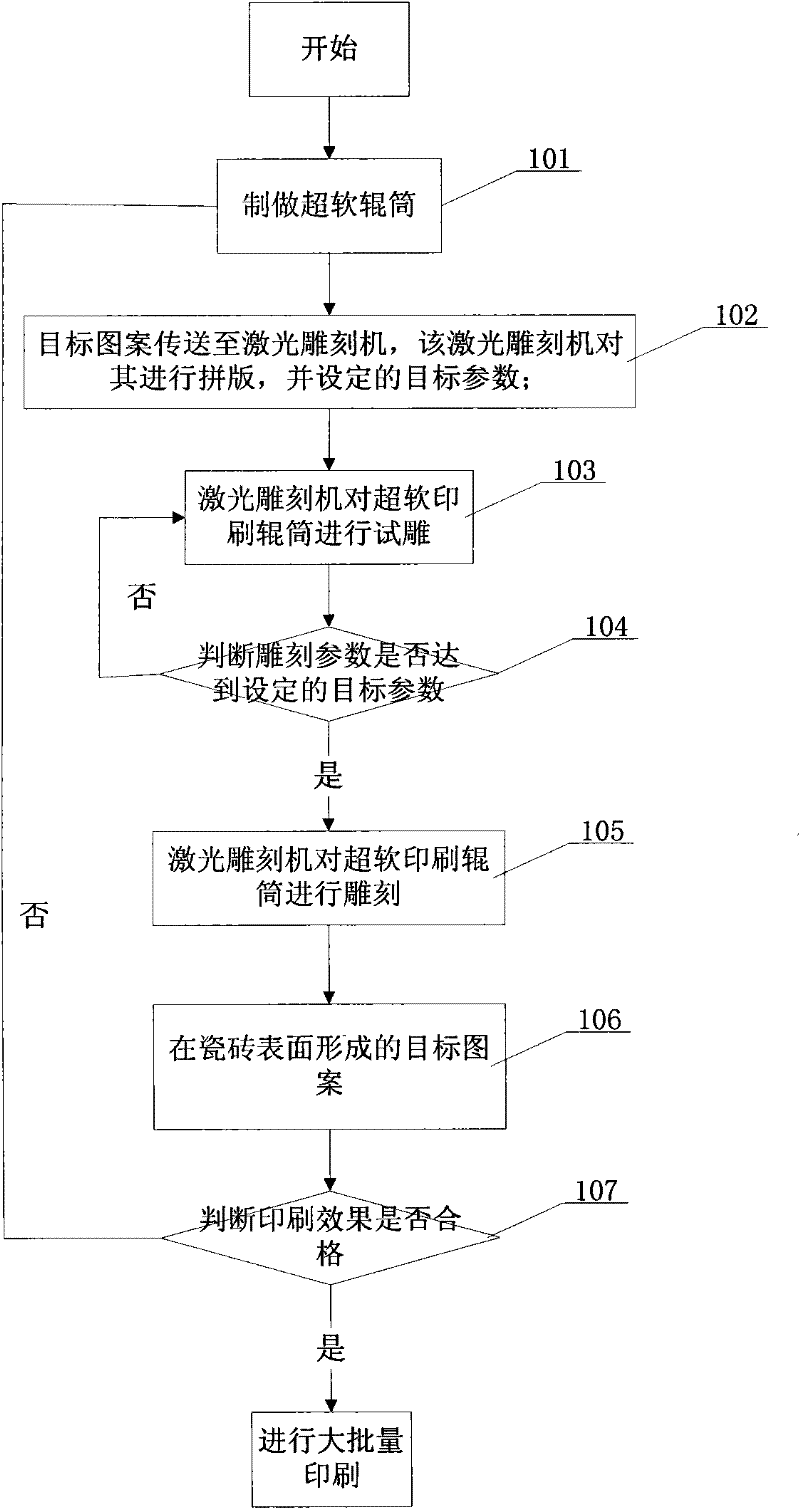

[0031] like figure 1 Shown, a kind of laser engraving processing method of supersoft printing cylinder is characterized in that, comprises the following steps:

[0032] 1) Silicone is processed to make a super soft printing roller suitable for ceramic tile printing and laser engraving;

[0033] 2) The PC transmits the target pattern to the laser engraving machine, and the laser engraving machine performs imposition of the target pattern and sets the target parameters for laser engraving;

[0034] 3) The laser engraving machine conducts test engraving on the ultra-soft printing roller;

[0035] 4) The laser engraving machine judges whether the engraving parameters reach the set target parameters, if yes, execute step 5), if no, return to step 3);

[0036] 5) The laser engraving machine engraves the ultra-soft printing roller, and forms a complete and smooth printing cell on the silicone surface of the ultra-soft printing roller after engraving;

[0037] 6) Fill glaze in thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com