UV-curing ink and method for preparing masking plate by using ink

A mask plate and ink technology, applied in the direction of ink, photomechanical processing originals, applications, etc., can solve the problems of high cost, hindering the improvement and development of mask plate making process, expensive and other problems, and achieve neat and clean edges Defect, effective preparation route, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A UV curable ink comprising:

[0032] (1) Polyurethane acrylate, accounting for 32% of the total mass percentage;

[0033] (2) α-hydroxycyclohexylbenzophenone, accounting for 8% of the total mass percentage;

[0034] (3) Tripropylene glycol diacrylate, accounting for 45% of the total mass percentage;

[0035] (4) black pigment, accounting for 13% of the total mass percentage;

[0036] (5) Additives, accounting for 2% of the total mass.

[0037] The additives include dispersants, defoamers, photosensitizers and light stabilizers, wherein the dispersant is alkylphenol polyoxyethylene ether, the defoamer is polydimethylsiloxane, and the photosensitizer is 2-hydroxy-2-methyl Base-1-propyl-1-acetone and light stabilizer are alkyl disulfides.

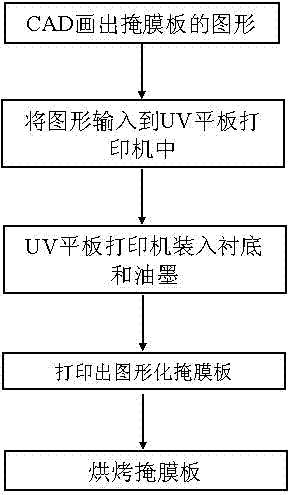

[0038] A method for preparing a mask:

[0039] Put the plexiglass substrate into the neutral ECB-868 cleaning agent to clean, then dry, put the UV ink into the UV flat-panel inkjet printer, turn on the UV flat-panel inkjet printer...

Embodiment 2

[0042] According to the preparation method of embodiment 1, the UV ink composition is changed to:

[0043] (1) Polyether acrylate resin, accounting for 30% of the total mass percentage;

[0044] (2) Isopropylthioxanthone, accounting for 6% of the total mass percentage;

[0045] (3) Trimethylolpropane triacrylate, accounting for 46% of the total mass percentage;

[0046] (4) black pigment, accounting for 15% of the total mass percentage;

[0047] (5) Additives, accounting for 3% of the total mass;

[0048] The dispersant is polyoxyethylene alkyl amide, the defoamer is polyoxypropylene glyceryl ether, the photosensitizer is 1-hydroxy-cyclohexyl-phenyl ketone, and the light stabilizer is silver chloride.

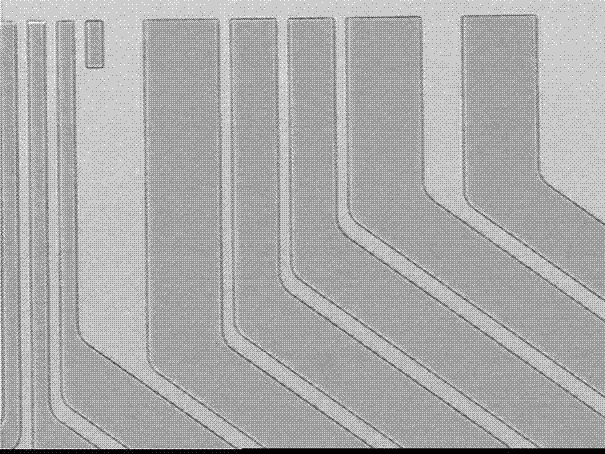

[0049] The plexiglass substrate in Example 1 was replaced by a polyimide film flexible substrate to prepare a mask for the flexible substrate. The micrographs of the Figure 5 As shown in the figure, it can be seen from the figure that the edges of the inkjet printed mask ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com