Ultrathin glass-organic film composite cover plate based on roll-to-roll process and manufacturing method thereof

A technology of ultra-thin glass and manufacturing methods, applied in chemical instruments and methods, glass/slag layered products, lamination auxiliary operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

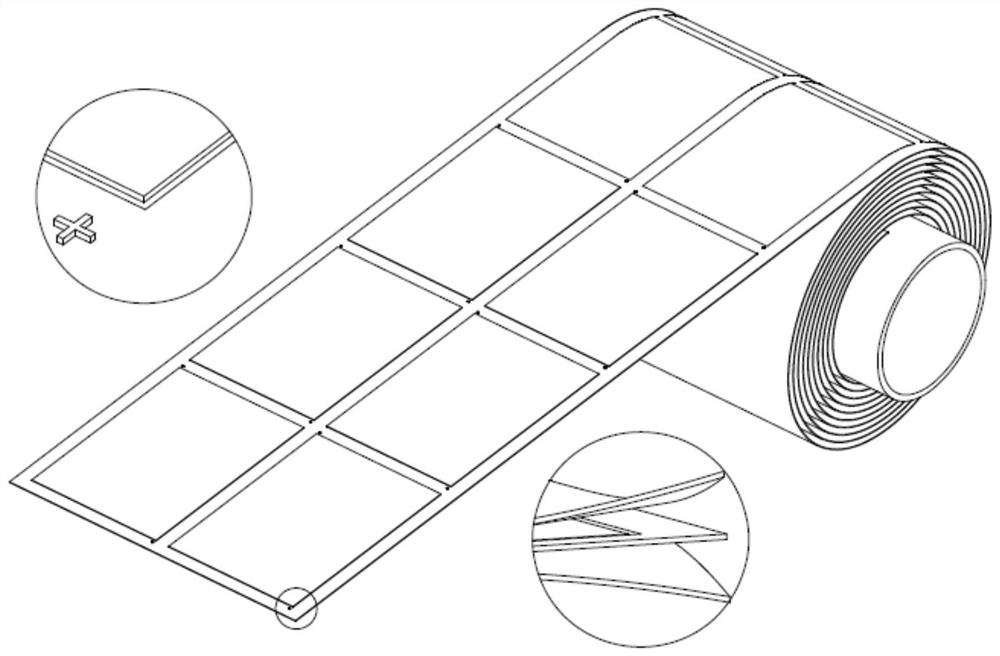

[0096] The ultra-thin glass-organic film composite cover plate that present embodiment makes is as figure 2 As shown, its preparation steps are as follows.

[0097] 1) Use a 100um PET silicone protective film roll with a roll diameter of 8 inches (the roll diameter must be greater than UTG and the stiffness after bending along the roll is less than its peeling force with the silicone), the silicone protection The film consists of a PET support layer with a thickness of 100um, an adhesive layer of silica gel formed on its surface from bottom to top, and a PET thickness balance medium layer with a thickness of 50um on the surface of the adhesive layer. The coil is baked in a tunnel oven at 150°C 1 hour;

[0098] 2) Use a laser cutting machine to cut the PET thickness balance medium layer with a thickness of 50um on the upper layer according to the shape of the UTG to be coated, with a length and width tolerance of +100um to form multiple ultra-thin glass storage grooves, and a...

Embodiment 2

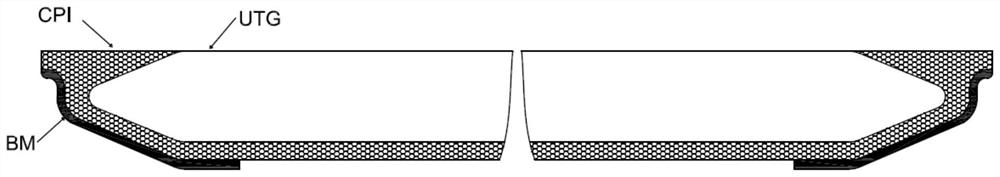

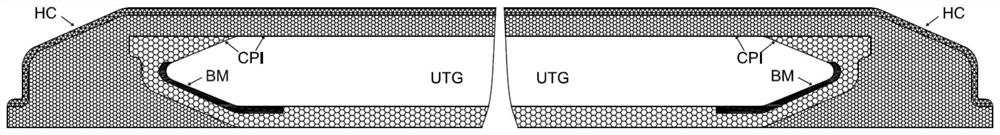

[0110] The ultra-thin glass-organic film composite cover plate that present embodiment makes is as image 3 As shown, its preparation steps are as follows.

[0111] 1) Use a 100um thick PET coil as a support and bake it in a tunnel oven at 150°C for 1 hour, then clean it, and after corona treatment, atomize and spray a layer of acrylic UV debonding adhesive layer on its surface as a bonding layer and Curing, the UTG with a thickness of 50um is neatly attached to the surface of the above-mentioned UV debonding adhesive layer and covered with a 50um PET thickness balance medium layer before winding;

[0112] 2) Use a laser to cut the upper 50um-thick PET thickness balance medium layer along the edge of the UTG (the size tolerance is +50um) and cut out the alignment marks. After cleaning with cleaning agent, high-pressure DI water cleaning and drying, cover with non-adhesive PE protective film, use 8-inch roll core to harvest rolls;

[0113] 3) Remove the PE protective film on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com