Patents

Literature

31results about How to "Uniform ink output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inkjet head

ActiveUS20120206540A1Reduce resistanceReduce in mechanical compliancePrintingElectrical and Electronics engineeringElectrode

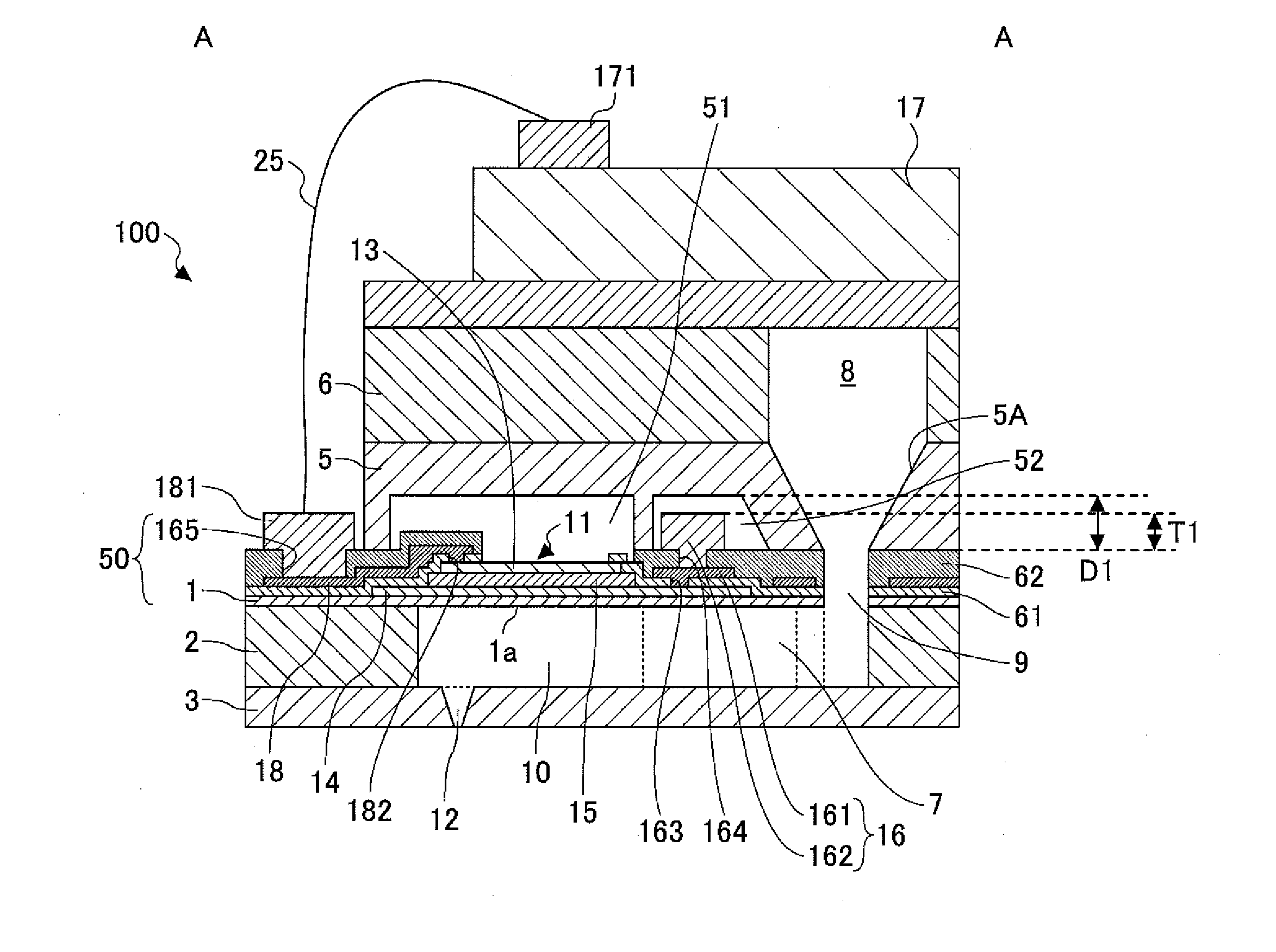

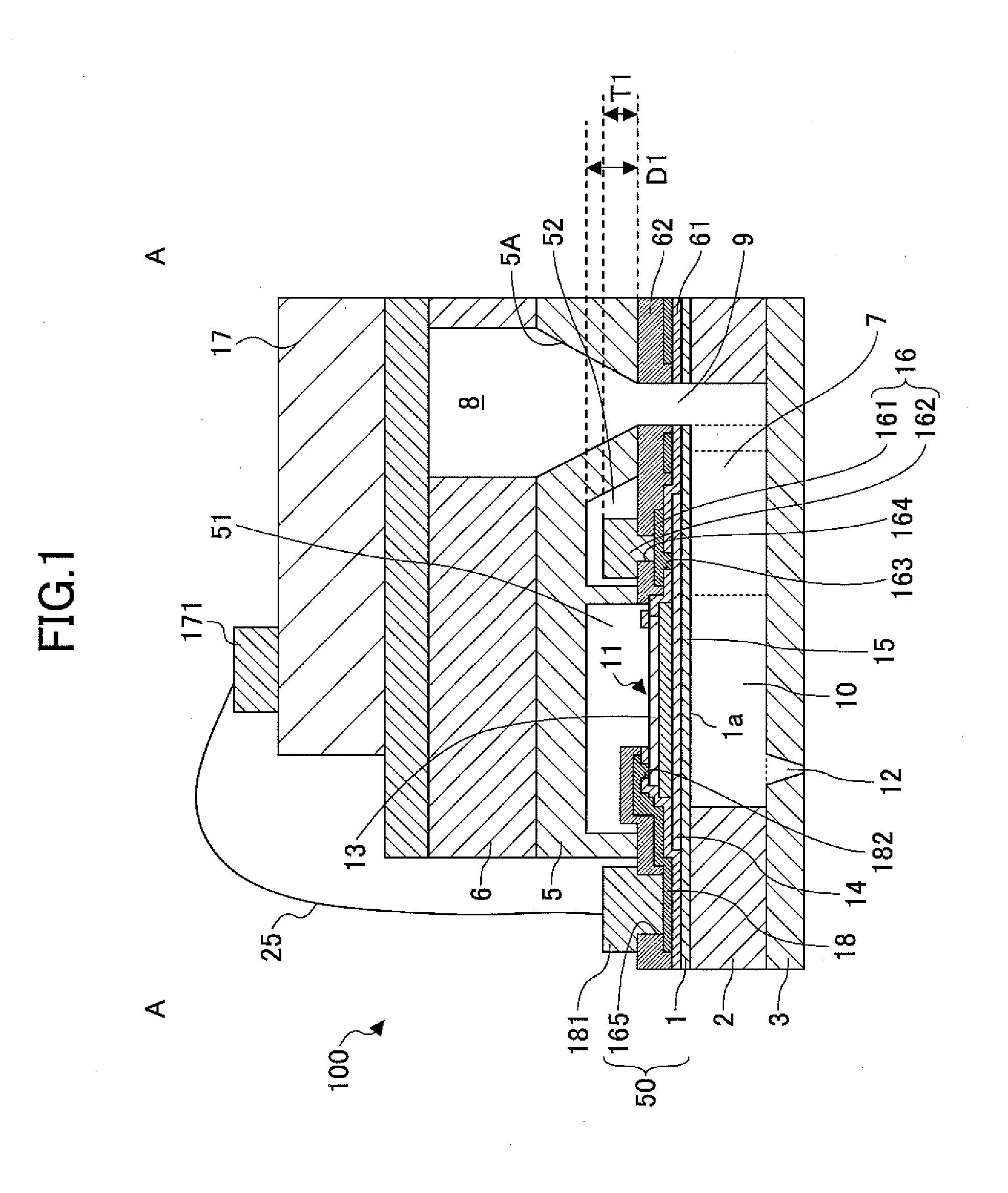

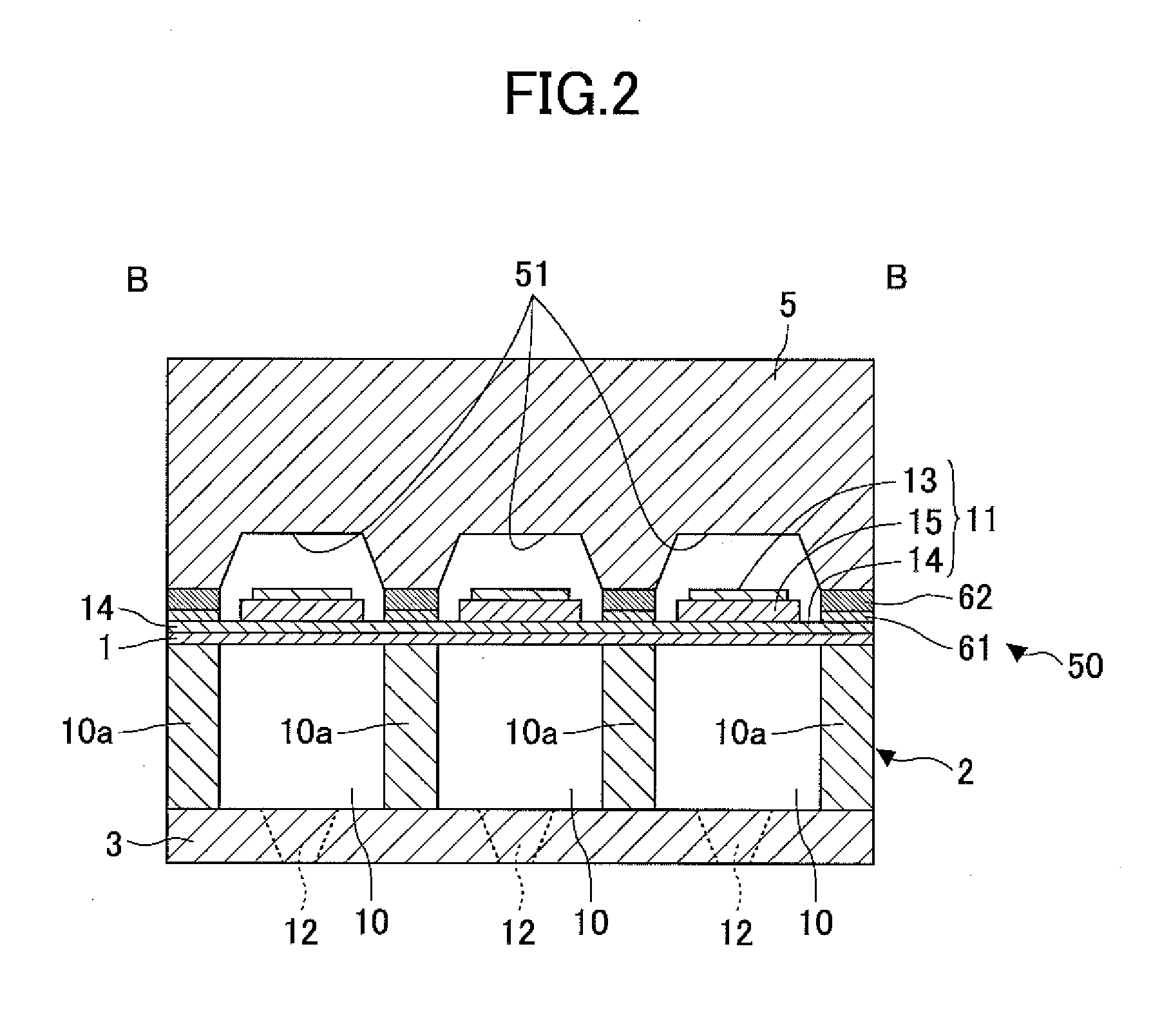

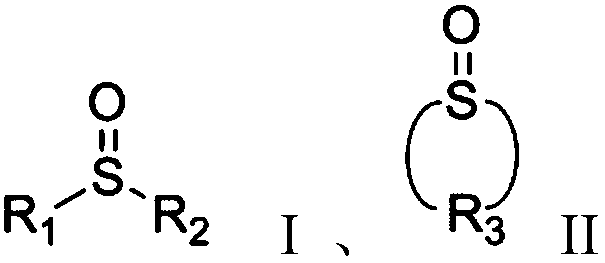

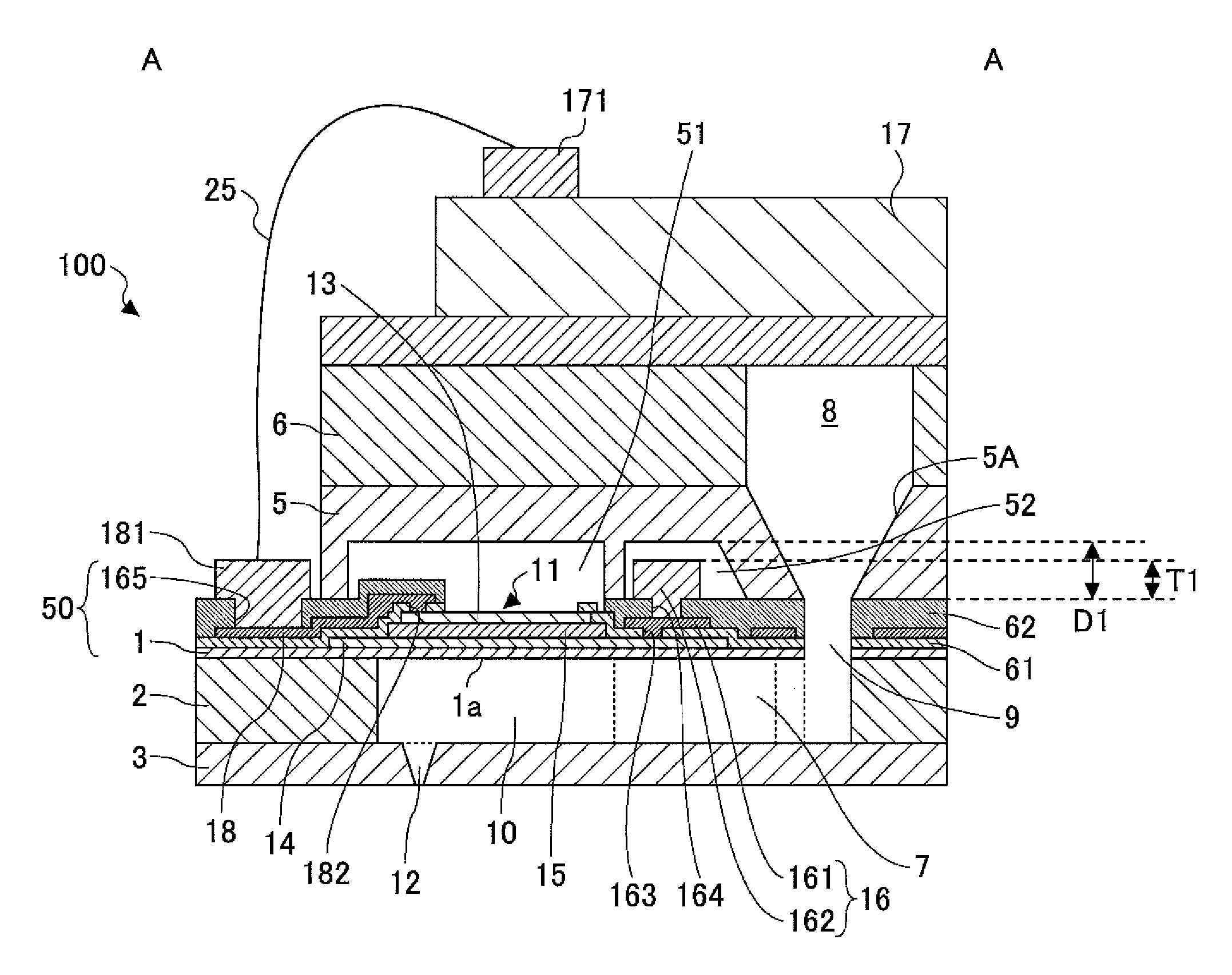

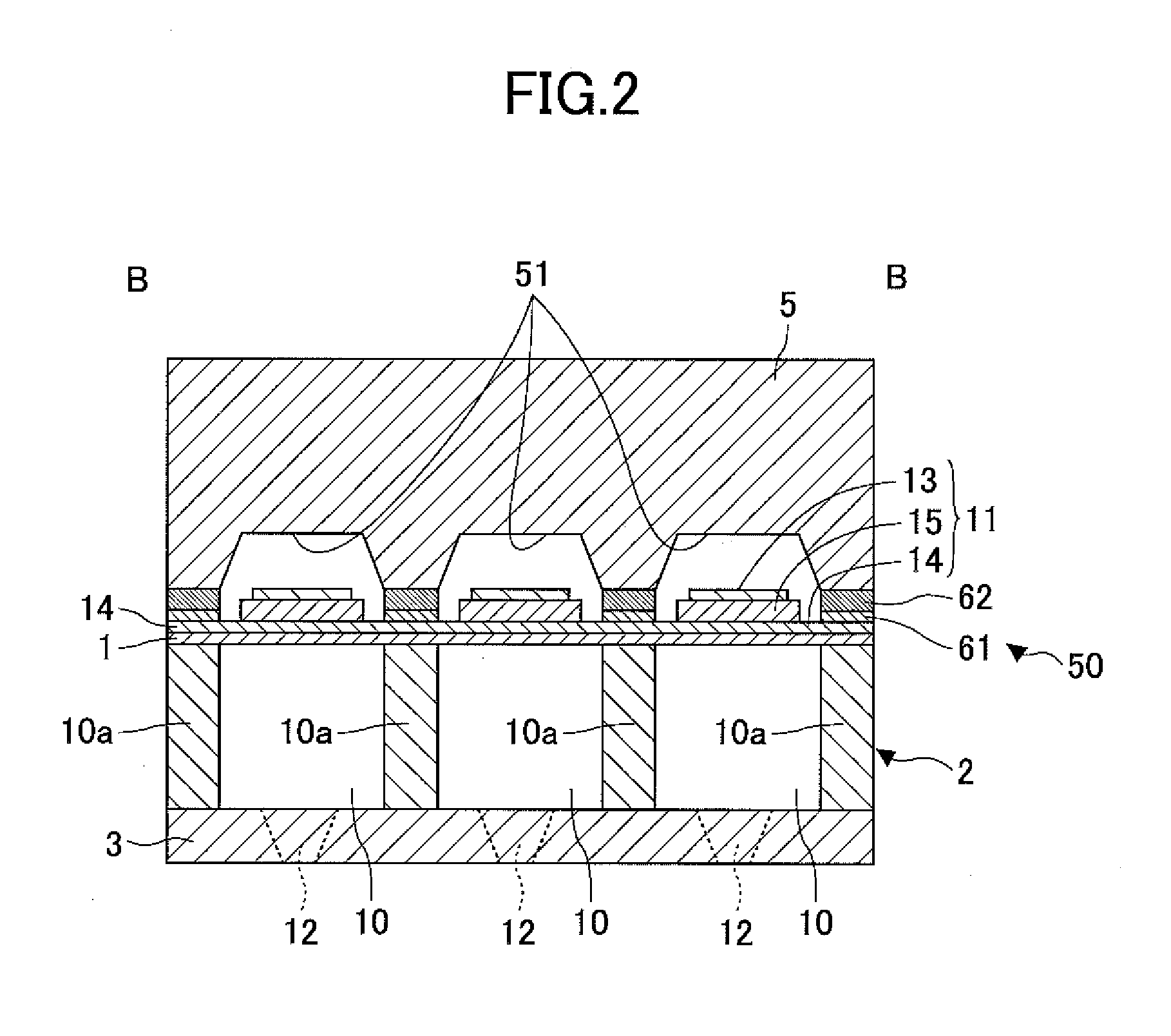

Disclosed is an inkjet head including a channel substrate; a multi-interconnect structure formed on the channel substrate, including a vibration layer, plural piezoelectric elements each including a first electrode, a piezoelectric layer and a second electrode, and a common electrode interconnect electrically connected to the first electrode including a first common electrode interconnect and a second common electrode interconnect which has a thickness thicker than that of the first common electrode interconnect; and a support substrate bonded to the channel substrate through the multi-interconnect structure, the support substrate being provided with a first concave portion at a surface facing the channel substrate at an area corresponding to the second common electrode interconnect to accommodate the second common electrode interconnect.

Owner:RICOH KK

White board pen ink and its making process

The white board pen ink has the recipe comprising pigment 3.5-5.0 %, uncapping agent 1.0-5.0 %, alcohol 48.0-71.0 %, propanol 15.0-25.0 %, erasing agent 5.0-10.0 %, resin 3.5-5.0 %, and dispersant 1.0-2.0 %. Its making process includes the following steps: mixing all the materials via stirring, grinding for 20-30 hr to reach pigment granularity of D50=120-200 nm, and discharging. The white board pen ink has fluent writing and high storage stability, is suitable for writing on white board, glass, plastic product, etc, and may be fitted to various kinds of pens.

Owner:苏州三威纳米科技有限公司

Ink for white board marker and method for manufacturing same

The invention discloses a white-board pen ink and preparing method, which comprises the following parts: 3.5-5.0% dye,1.0-5.0% decapping agent,48.0-71.0% alcohol,15.0-25.0% propanol,5.0- 10.0% erasable agent,3.5-5.0% resin and 1.0-2.0% dispersant. the preparing method comprises the following steps: adding alcohol and propanol in the predispersing stove; stirring to add decapping agent, erasable agent, resin and dispersant until dissolving evenly; adding dye; stirring completely; grinding for 20-30h until the grain size D50 of dye particle reaches 120-200nm; discharging.

Owner:苏州三威纳米科技有限公司

Water-based nano pigment-type gel pen ink and preparation method thereof

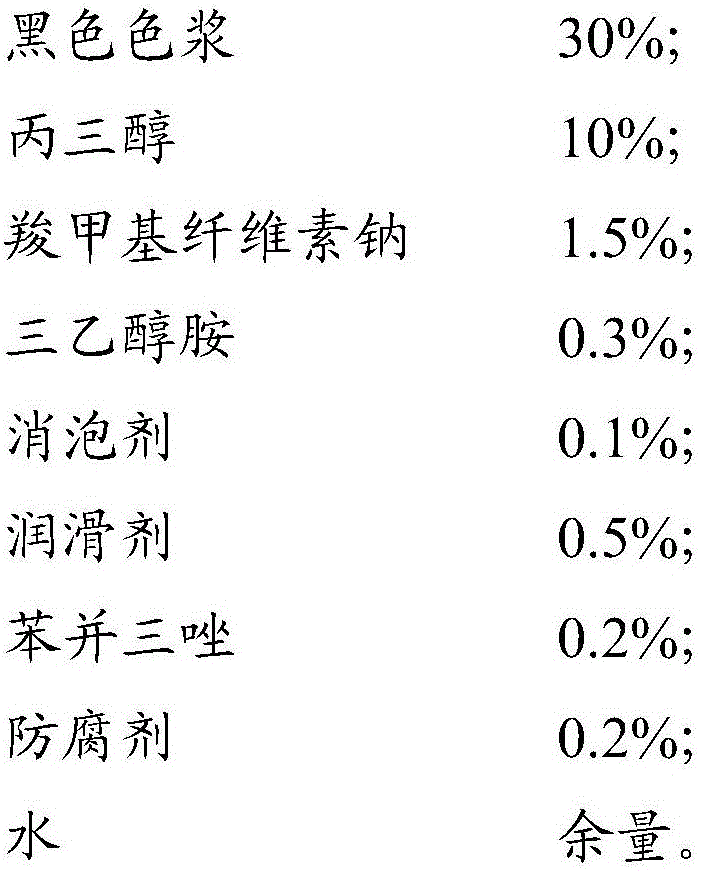

The invention relates to a water-based nano pigment-type gel pen ink and a preparation method thereof. The water-based nano pigment-type gel pen ink comprises the following components in percentage by weight: 20-40% of resin-free nano color paste, 10-30% of humectant, 0.1-3% of thickener, 0.2-3% of pH regulator, 0.05-0.5% of defoaming agent, 0.1-3% of lubricant, 0.2-2% of rust inhibitor, 0.2-2% of preservative and the balance of deionized water. The average particle size of the resin-free nano color paste is 100-250nm. The preparation method comprises the following steps: sufficiently stirring and uniformly mixing the components, and defoaming. By using the resin-free nano color paste, the ink has the advantages of favorable stability, proper viscosity, uniform particle fineness, smooth writing and uniform ink release without floating. The ink has the characteristics of bright color, light fastness, high water resistance and high stable quality after long-term storage, and can not have the phenomenon of stratification, precipitating deterioration or the like. The sand mill is used for grinding, so that the particle size of the pigment particles reaches nano scale. The preparation method is simple to operate and reasonable in technique.

Owner:SHANTOU WANHUI IND CO LTD

Waterproof type neutral ink with pigment in Nano level for pen, and preparation method

This invention provides a method for producing nanoscale pigment waterproof neutral pen ink, which comprises: nanoscale stock solution 40 wt. %, thickener 40-50 wt. %, and diluter 10-20 wt. %. The average particle size of the pigment is 100-200 nm. The method comprises: adding nanoscale stock solution into a blending pot, adding diluter under stirring, stirring for another 30-90 min, adding thickener, then stirring for 1-3 h, terminating stirring, and discharging. The ink has such advantages as good color, stable quality, fluent writing, high fatigue resistance, no demixing, separation or precipitation after a long-time storage, high solarization resistance, high waterproof performance, no toxicity, high production and usage safety, and no pollution. The ink can be widely used for metal ballpoint pen, polypropylene pen and plastic pen.

Owner:苏州三威纳米科技有限公司

Quantum dot ink and quantum dot light emitting diode preparation method

InactiveCN109021700ASpread evenlyStable spreadingMaterial nanotechnologyInksOrganic solventQuantum dot

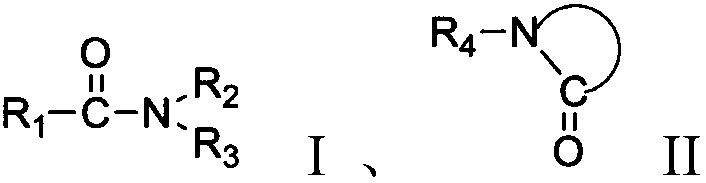

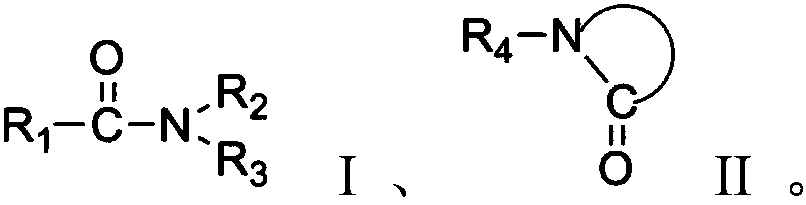

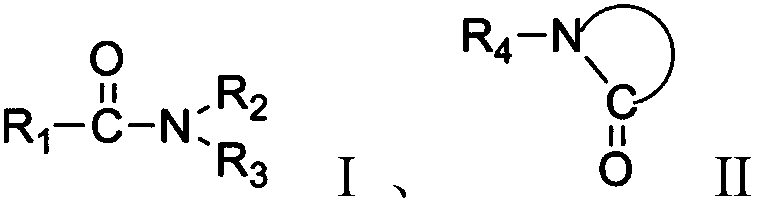

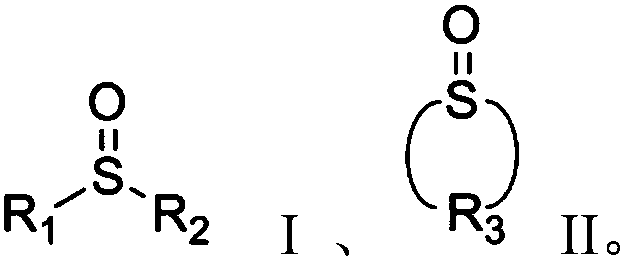

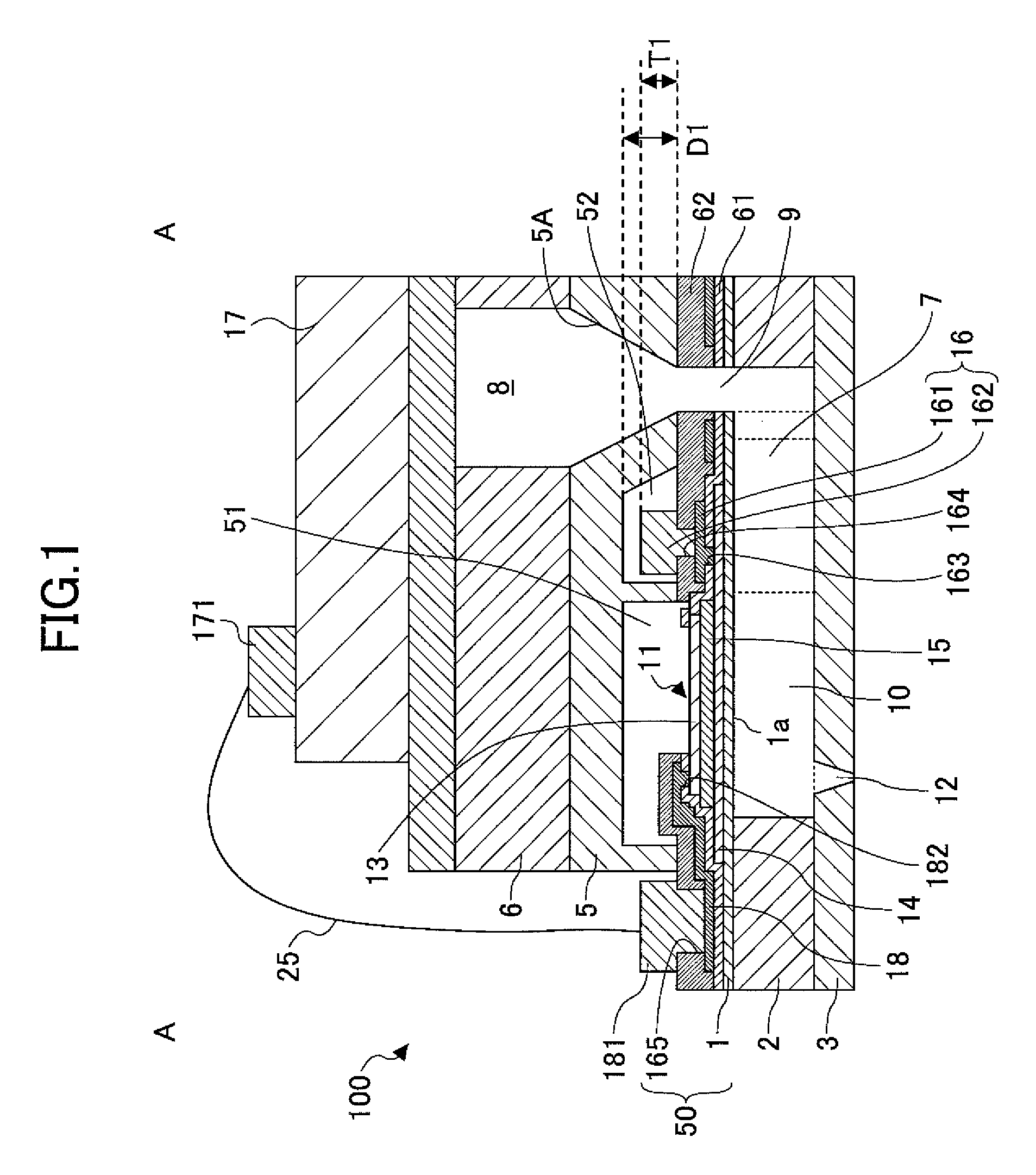

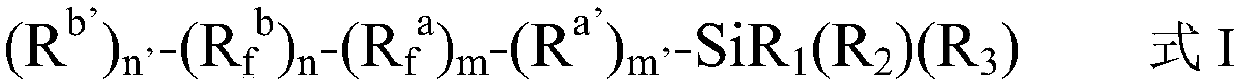

The invention provides a quantum dot ink and a quantum dot light emitting diode preparation method. The quantum dot ink comprises at least a quantum dot material and at least an amide-based organic solvent, wherein the molecular structure formula of the amide-based organic solvent is represented by a structural general formula I or / and II defined in the specification, the R<1>-R<3> contained in the structural general formula I are the same or different, and are any one group selected from C1-30 aliphatic and aromatic groups, or one of the R<2> and the R<3> is H, the other of the R<2> and the R<3> is the same as or different from the R <1>, and is any one group selected from C1-30 aliphatic and aromatic groups, and the R<4> contained in the structural general formula II is any one group selected from C1-30 aliphatic and aromatic groups. The quantum dot light emitting diode preparation method comprises: preparing a quantum dot light emitting layer by using the quantum dot ink through anink jet printing method.

Owner:TCL CORPORATION

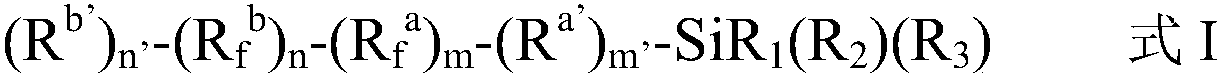

Printing ink using inorganic nanometer material and preparation method and application thereof

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing silane organic solvent, wherein the structure of the fluorine-containing silane organic solvent is shown in a formula I, namely (Rb')n'-(Rfb)n-(Rfa)m-(Ra')m'-SiR1(R2)(R3); in the formula I, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Rb' is independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine), I (iodine), sulphonate, sulfonyl ester, and methoxyl; Ra' is selected from aliphatic group with C1 to C30, aromatic group, sulphonate, sulfonyl ester, and methoxyl; R1, R2 and R3 are independently selected from H, hydroxyl or substituted hydroxyl, and aryl or substituted aryl; the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:SHENZHEN TCL IND RES INST

Inorganic nanometer material printing ink, preparation method and applications thereof

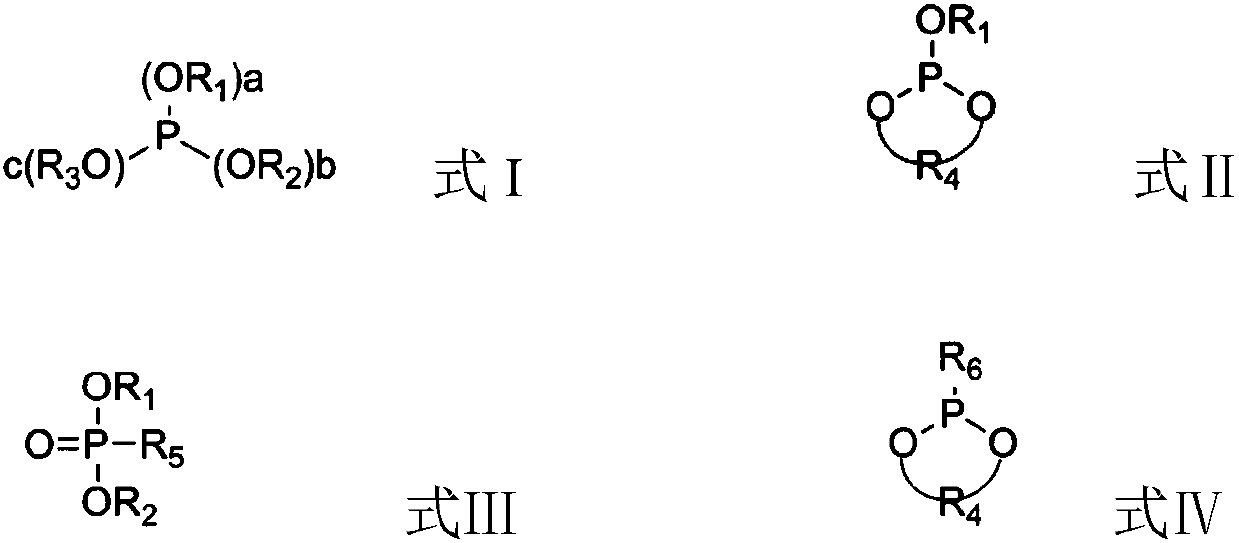

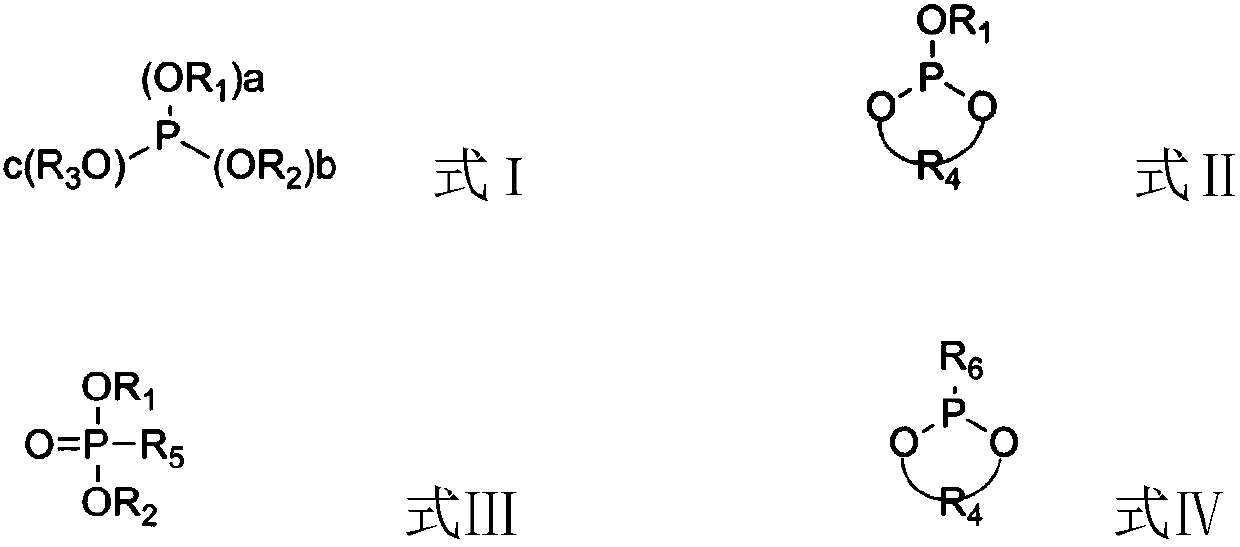

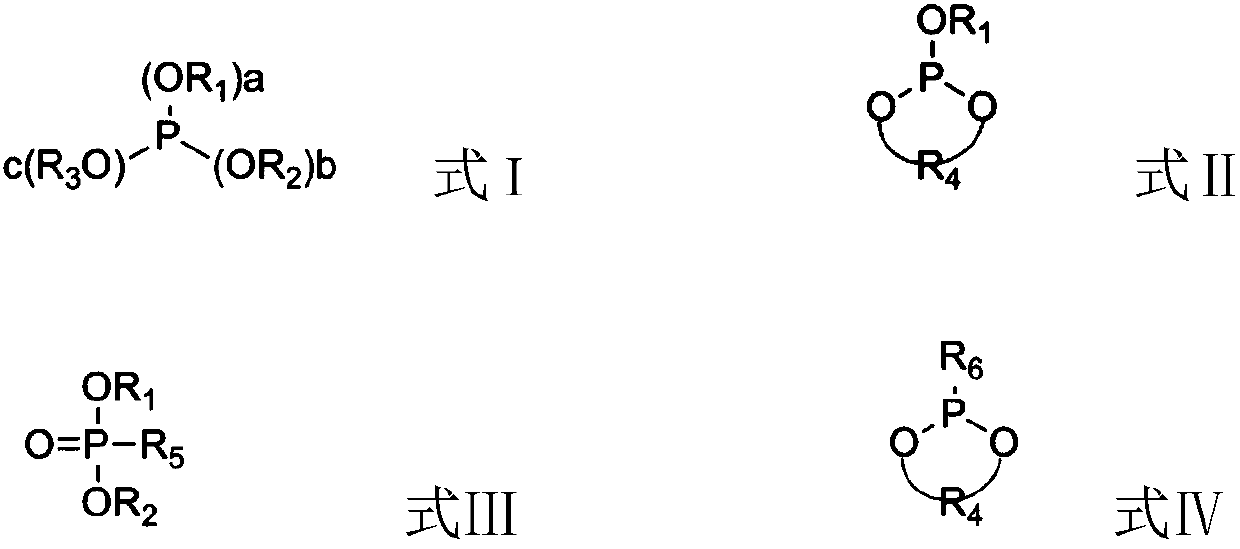

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a phosphite-based organic solvent, the phosphite-based organic solvent has a structure represented by any one of structure formulas I, II, III and IV, and in the formulas I, II, III and IV, R1, R2 and R3 are independently selected from H and C1-30 aliphatic groups or aromatic groups, at most one of R1, R2 and R3 is H, R4 is selected from a C1-30 aliphatic group or aromatic group, R5 is selected from H, hydrocarbonyl and a hydrocarbonyl derivative, R6 is selected from H, hydrocarbonyl and a hydrocarbyl derivative, a, b and care individually selected from an integer of 0-3, and the sum of a, b and c is 3.

Owner:TCL CORPORATION

Waterproof neutral ink with nanometer level pigment and its prepn

The waterproof neutral ink with nanometer level pigment consists of nanometer level material liquid 40 wt%, thickener 40-50 wt% and diluent 10-20 wt%, and has average size of 100-200 nm. The preparation process includes the following steps: setting the nanometer level material liquid in the compounding pot, adding the diluent while stirring, and stirring for further 30-90 min, adding the thickener, stirring for further 1-3 hr, and discharging. The neutral ink has bright color, stable quality, writing fluency and other advantages, and may be filled into different kinds of pens.

Owner:苏州三威纳米科技有限公司

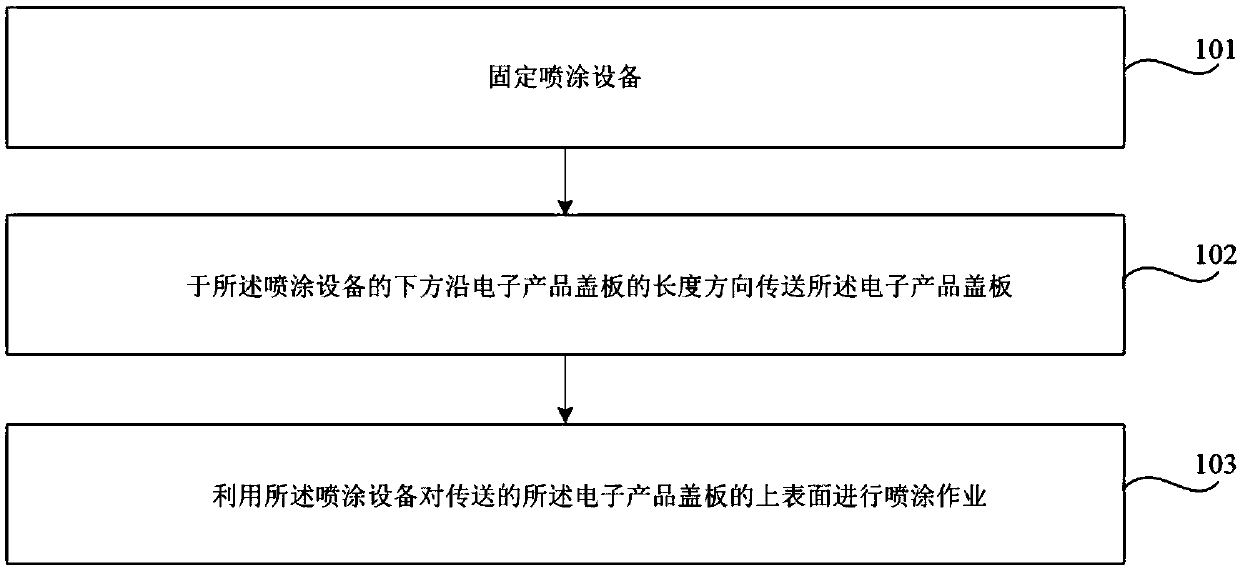

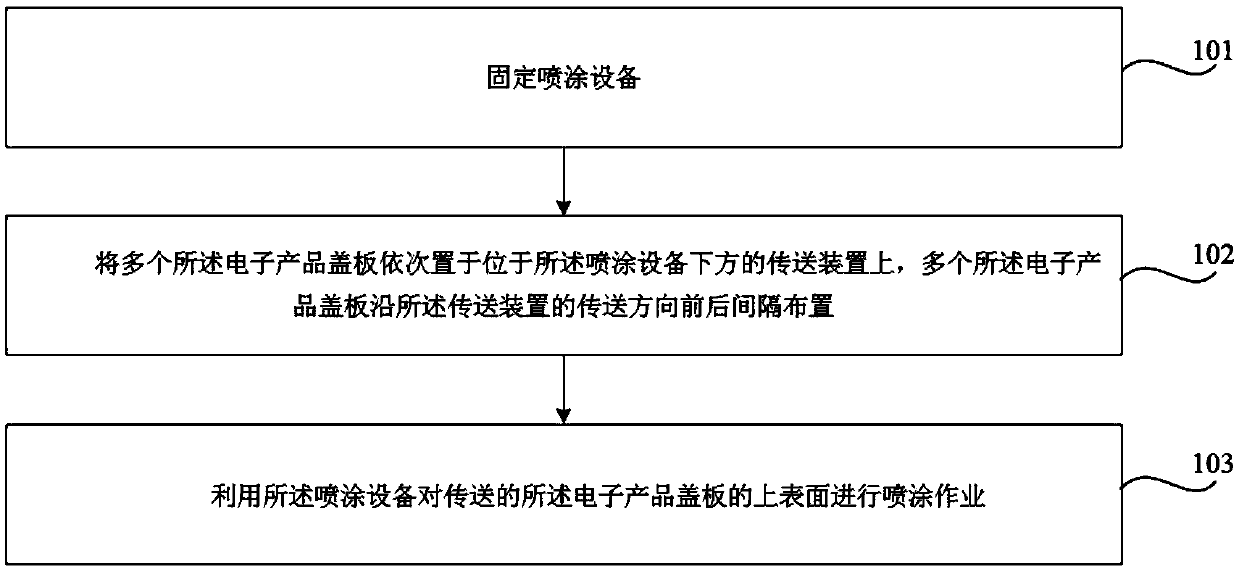

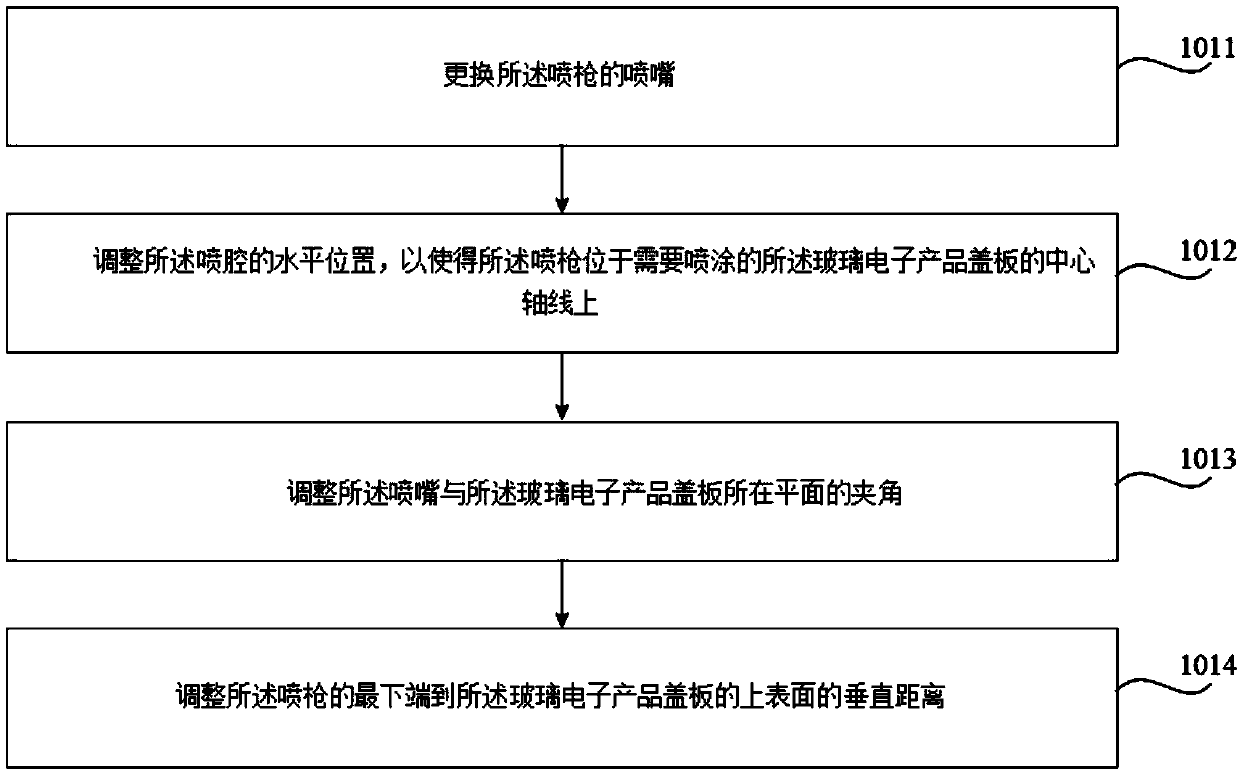

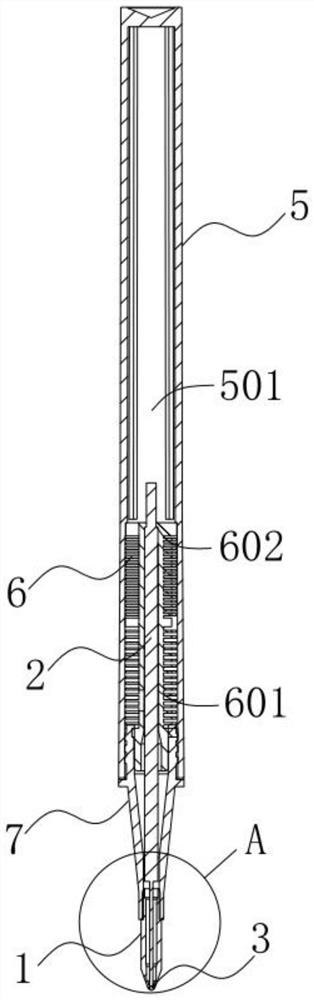

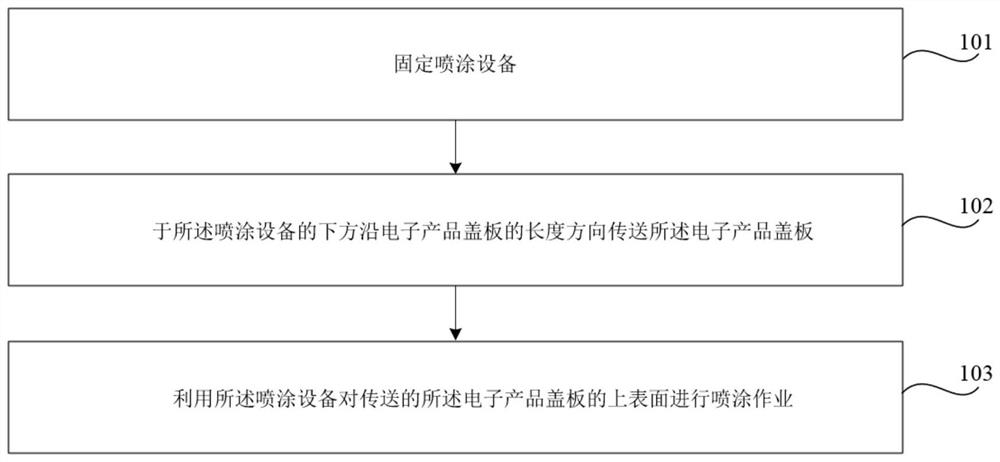

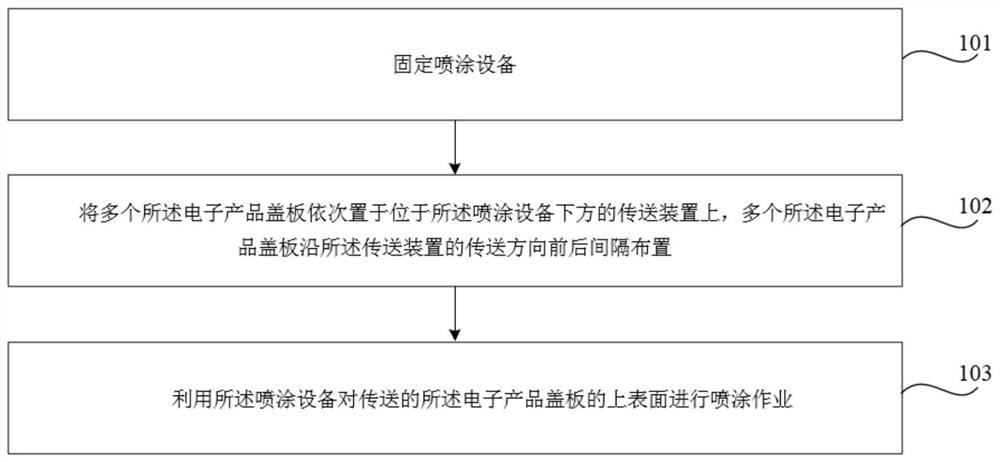

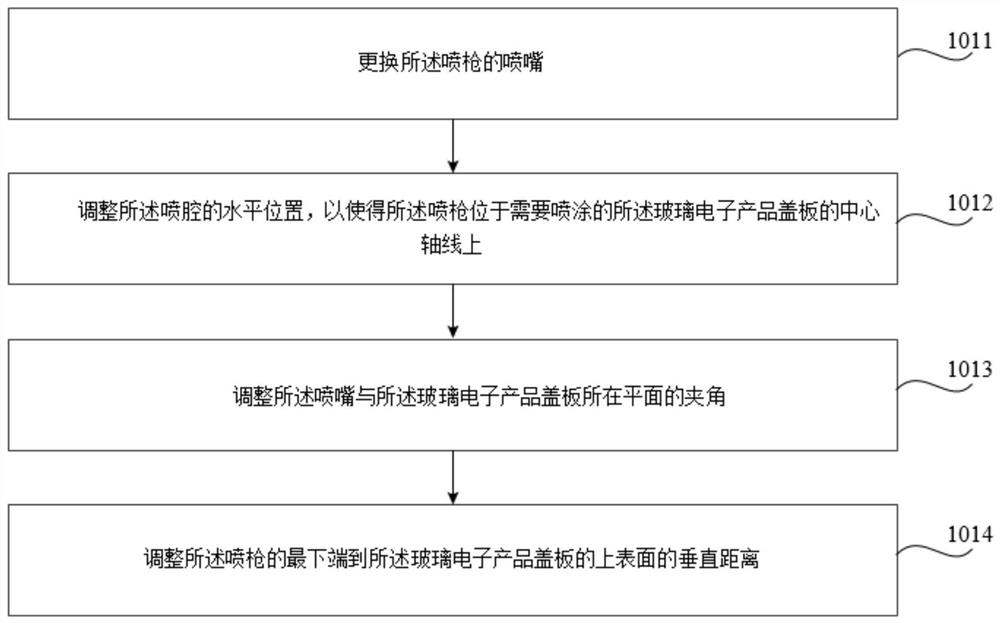

Electronic product outer shell as well as electronic product cover plate spraying method and spraying device

ActiveCN110813587AAchieve full coverage sprayingSmall film thickness errorLiquid surface applicatorsCoatingsMechanical engineeringIndustrial engineering

The invention relates to an electronic product outer shell as well as an electronic product cover plate spraying method and spraying device. The spraying method involves a fixing spraying device, andan electronic product cover plate is conveyed in the length direction of the electronic product cover plate below the spraying device; and the method comprises performing spraying operation on the upper surface of the conveyed electronic product cover plate through using the spraying device, and during the step of performing spraying operation on the upper surface of the conveyed electronic product cover plate through using the spraying device, the effective spraying width of the spraying device is larger than the width of the electronic product cover plate. In this way, the spraying device isfixed, and the electronic product cover plate is conveyed below the spraying device for being subjected to spraying operation, assembly line type and batch quantitative operation can be achieved, thespraying efficiency is improved; and meanwhile, the effective spraying width of the spraying device is far larger than the width of the electronic product cover plate, and the effective area of ink atomization completely coats the electronic product cover plate, so that full-covering type spraying of the electronic product cover plate is achieved.

Owner:BYD CO LTD

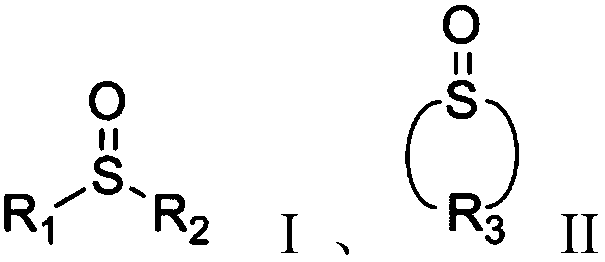

Quantum dot ink and quantum dot light emitting diode preparation method

InactiveCN109021701AImprove storage stabilityUniform film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotQuantum dot laser

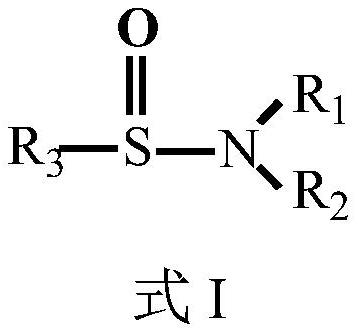

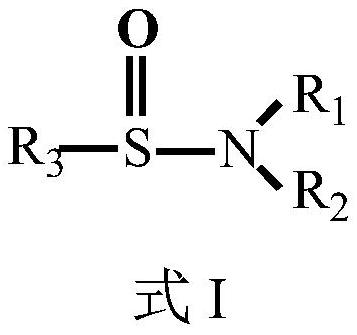

The invention provides a quantum dot ink and a quantum dot light emitting diode preparation method. The quantum dot ink comprises at least a quantum dot material and at least a sulfoxide-based organicsolvent, wherein the molecular structure formula of the sulfoxide-based organic solvent is represented by a structural general formula I or / and II defined in the specification, the R<1> and the R<2>contained in the structural general formula I are the same or different, and are any one group selected from C1-30 aliphatic and aromatic groups, or one of the R<1> and the R<2> is H, the other of theR<1> and the R<2> is any one group selected from C1-30 aliphatic and aromatic groups, and the R<3> contained in the structural general formula II is any one group selected from C1-30 aliphatic and aromatic groups. The quantum dot light emitting diode preparation method comprises: preparing a quantum dot light emitting layer by using the quantum dot ink through an ink jet printing method.

Owner:TCL CORPORATION

Inkjet head

ActiveUS8491103B2Reduce resistanceReduce compliancePrintingElectrical and Electronics engineeringElectrode

Disclosed is an inkjet head including a channel substrate; a multi-interconnect structure formed on the channel substrate, including a vibration layer, plural piezoelectric elements each including a first electrode, a piezoelectric layer and a second electrode, and a common electrode interconnect electrically connected to the first electrode including a first common electrode interconnect and a second common electrode interconnect which has a thickness thicker than that of the first common electrode interconnect; and a support substrate bonded to the channel substrate through the multi-interconnect structure, the support substrate being provided with a first concave portion at a surface facing the channel substrate at an area corresponding to the second common electrode interconnect to accommodate the second common electrode interconnect.

Owner:RICOH KK

Environmental-protection ink for hydraulic type water-based pen and preparation method thereof

InactiveCN103819966AImprove dispersion stabilityLow viscosityChemical industryInksEnvironmental engineeringChemical products

The invention relates to an environmental-protection ink for a hydraulic type water-based pen and a preparation method thereof, and belongs to the technical field of chemical product preparation. The environmental-protection ink comprises the components in parts by weight: 3.0-10.0 parts of a pigment, 3.0-8.0 parts of a resin, 2.0-5.0 parts of a dispersing agent, 2.0-10.0 parts of a moisturizing agent, and 90.0-67.0 parts of a solvent. The preparation method comprises the preparation steps: firstly adding the solvent into a pre-dispersing pot, successively adding the dispersing agent, the resin and the moisturizing agent according to the formula ratio with stirring until being completely dissolved evenly, finally, adding the pigment, fully stirring and mixing, then carrying out micro-grinding for 2-8 hours to make the pigment particle diameter reach a specific size, stopping grinding, and discharging. The ink prepared by the method has the advantages of bright-colored color, low viscosity, uniform ink discharging, smooth writing, stable quality, energy saving, environmental protection, convenient use, simple process and low cost, does not paste boards, and is easy to wipe.

Owner:胡志新

Inorganic nanometer material printing ink, preparation method and applications thereof

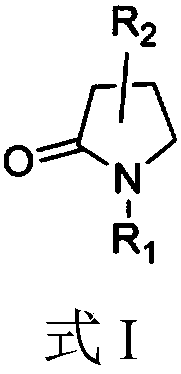

InactiveCN109929327AImprove stabilityGood dispersionInksSemiconductor devicesOrganic solventPrinting ink

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a pyrrolidone-based organic solvent, the pyrrolidone-based organic solvent has a structure represented by a structure general formula I, and in the formula I, R1 and R2 are independently selected from C1-C20 aliphatic groups and C1-20 aromatic groups.

Owner:TCL CORPORATION

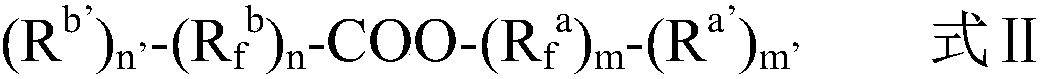

Printing ink using inorganic nanometer material and preparation method and application thereof

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing ester organic solvent, wherein the structure of the fluorine-containing ester organic solvent is shown in a formula II, namely (Rb')n'-(Rfb)n-COO-(Rfa)m-(Ra')m'; in the formula II, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Ra' and Rb' are independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:TCL CORPORATION

Flexible printing process for corrugated cartons

InactiveCN111959144AAvoid erosionAvoid shellingOther printing apparatusPrinting press partsCartonPrinting press

The invention discloses a flexible printing process for corrugated cartons, relates to the technical field of flexible printing, and aims to solve the problems that performance of an existing flexibleprinting process for corrugated cartons is not perfect enough and the working efficiency is low. The process comprises the steps that S1, a plate cylinder is cleaned; S2, a base surface of a photosensitive resin plate is cleaned and dried by using a detergent; S3, a hard board double-sided adhesive tape is pasted to the plate cylinder; S4, a photosensitive resin plate printing plate is pasted onthe plate cylinder, and edge sealing is conducted by using a sealant; S5, an anilox roller is cleaned, and the plate cylinder and an anilox roller plate cylinder are installed separately; S6, a scraper blade is cleaned, and the scraper blade is mounted in a scraper chamber; S7, an ink box is cleaned, the ink box is installed, and then water-based ink is poured into the ink box; and S8, printing iscarried out on a corrugated board by a flexible printing machine.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD

Printer ink box capable of being filled with ink repeatedly

Owner:XIAN YOUQING COMMERCE & TRADE CO LTD

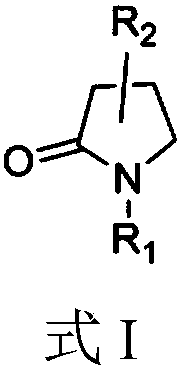

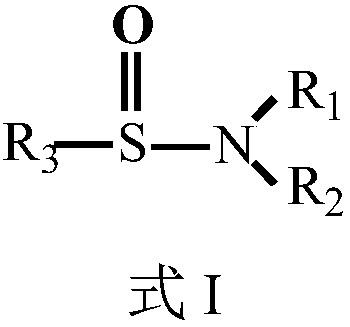

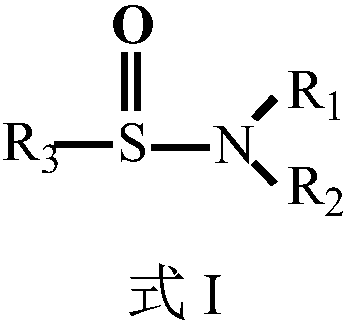

Inorganic nanometer material printing ink, preparation method and applications thereof

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a sulfinamide-based organic solvent, the sulfinamide-based organic solvent has a structure represented by a structure general formula I, and in the formula I, R1 and R2 are independently selected from H, C1-20 aliphatic groups and C1-20 aromatic groups, R3 is selected from hydrocarbonyl or a hydrocarbonyl derivative, the hydrocarbonyl comprises aliphatic hydrocarbonyl and aromatic hydrocarbonyl, and the hydrocarbonyl derivative comprises an aliphatic hydrocarbonyl derivative and an aromatic hydrocarbonyl derivative.

Owner:TCL CORPORATION

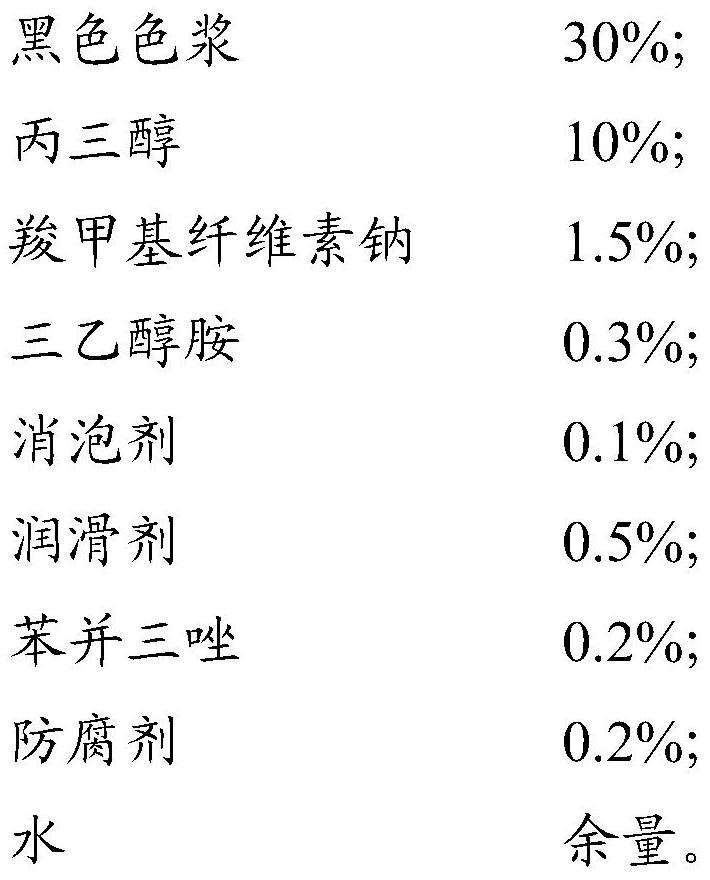

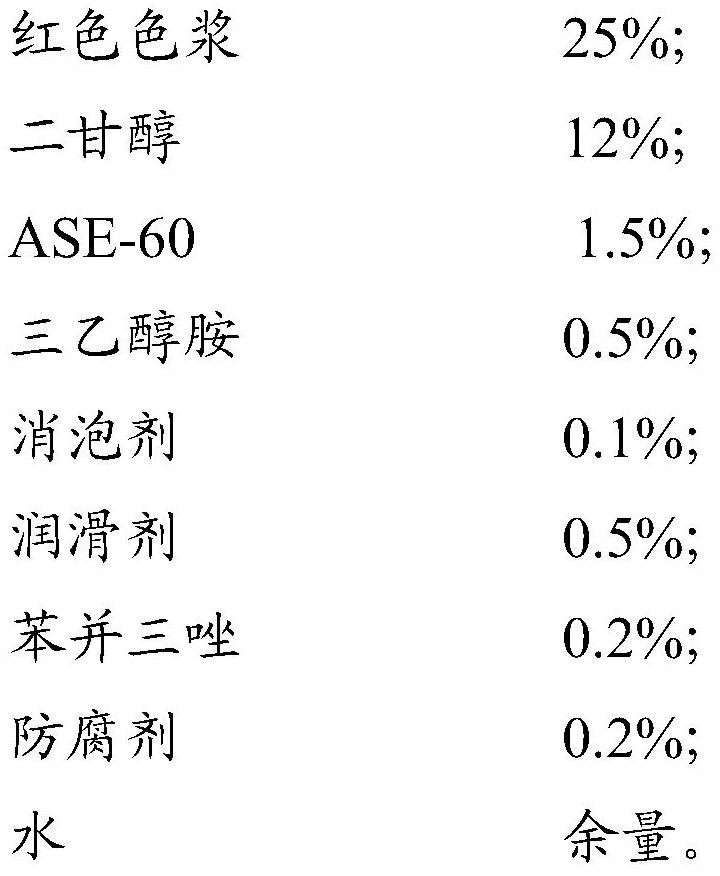

A kind of water-based nano pigment type neutral pen ink and preparation method thereof

The invention relates to a water-based nano-pigment type neutral pen ink and a preparation method thereof. Thickener 10‑30%, thickener 0.1‑3%, pH regulator 0.2‑3%, defoamer 0.05‑0.5%, lubricant 0.1‑3%, rust inhibitor 0.2‑2%, preservative 0.2‑2 %, the rest is deionized water; the average particle diameter of the resin-free nano-color paste is 100-250nm. The preparation method is as follows: fully stir and mix each component evenly, and then defoam. The invention adopts the resin-free nano-color paste to make the ink have good stability, proper viscosity, uniform particle fineness, smooth writing, uniform ink output, no flowering; bright color, light fastness, strong water resistance, and long-term storage quality is stable , There will be no stratification, precipitation and deterioration. The preparation adopts a sand mill to grind, so that the particle size of the pigment particles reaches the nanometer level, and the operation is simple and the process is reasonable.

Owner:SHANTOU WANHUI IND CO LTD

Printing ink using inorganic nanometer material and preparation method and application thereof

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing alcohol organic solvent, wherein the structure of the fluorine-containing alcohol organic solvent is shown in a structural formulaVIII, namely [(Rb')n'-(Rfb)n-(Rfa)m-(Ra')m']-OH; in the formula VIII, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Ra' and Rb' are independently selectedfrom H (hydrogen), fatty group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); -OH is connected with carbon atom, and is not directly connected with benzene ring carbon; the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:SHENZHEN TCL IND RES INST

Printing ink using inorganic nanometer material and preparation method and application thereof

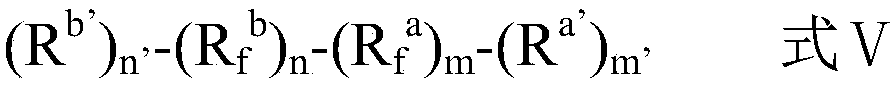

InactiveCN109810568AEvenly dispersedAppropriate volatilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventPrinting ink

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing aromatic hydrocarbon organic solvent, wherein the structure of the fluorine-containing aromatic hydrocarbon organic solvent is shown in a formula V, namely (Rb')n'-(Rfb)n-(Rfa)m-(Ra')m'; Rfa is selected from partially or totally fluorated alkyl; in the formula V, Rfb is selected from partially and totally fluorated aromatic hydrocarbon or non-fluorated aromatic hydrocarbon; Ra' and Rb' are independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group with C5 to C30, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1; whenn is 0, at least one of Ra' and Rb' is the aromatic group with C5 to C30; when m is 0, Rfb is selected from the partially or totally fluorated aromatic hydrocarbon.

Owner:TCL CORPORATION

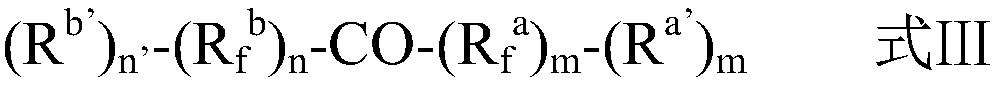

Printing ink using inorganic nanometer material and preparation method and application thereof

InactiveCN109810573AChemically stableGood chemical resistanceSolid-state devicesSemiconductor/solid-state device manufacturingArylHydrogen

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing ketone organic solvent, wherein the structure of the fluorine-containing ketone organic solvent is shown in a formula III, namely (Rb')n'-(Rfb)n-CO-(Rfa)m-(Ra')m'; in the formula III, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Ra' and Rb' are independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:TCL CORPORATION

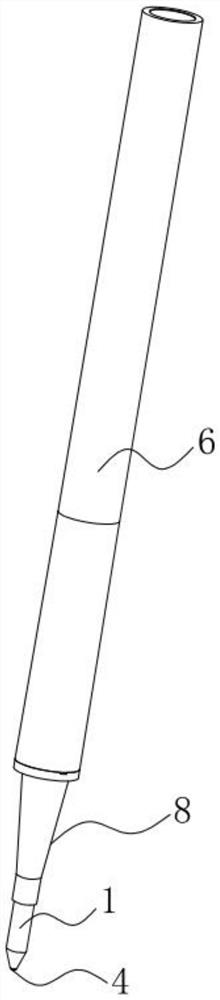

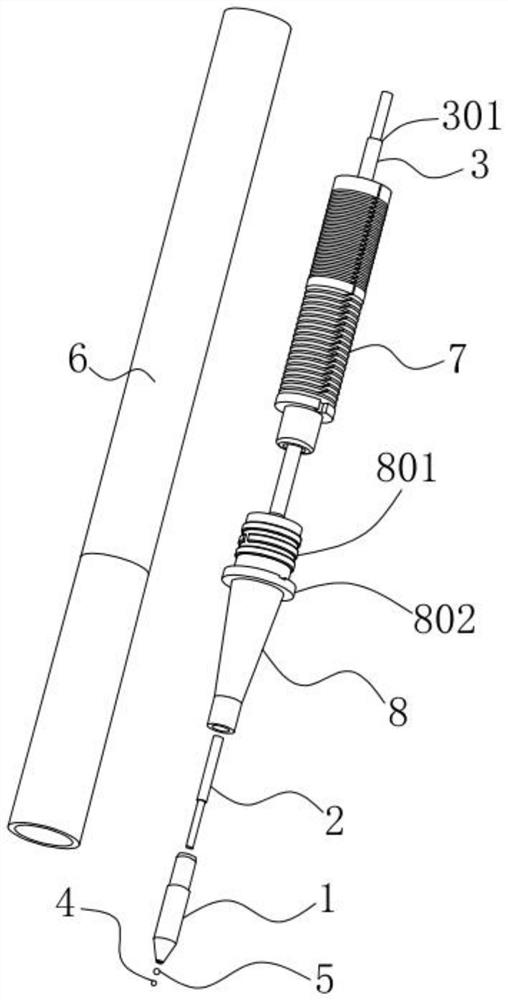

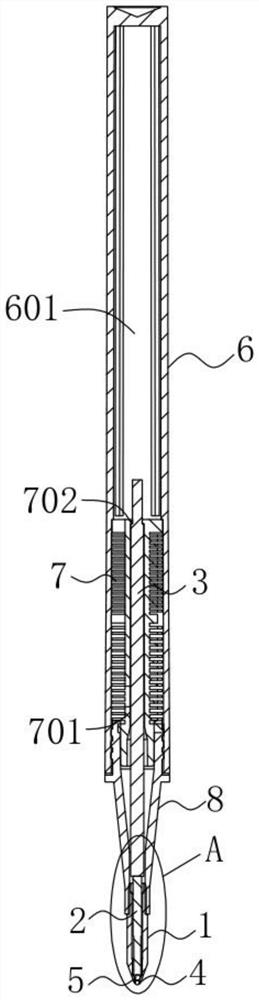

Direct liquid type refill capable of being used for pressing writing pen

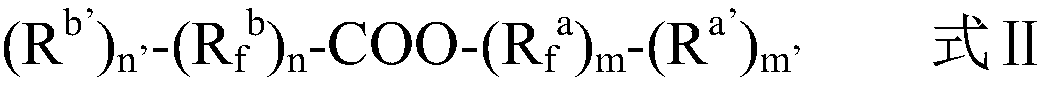

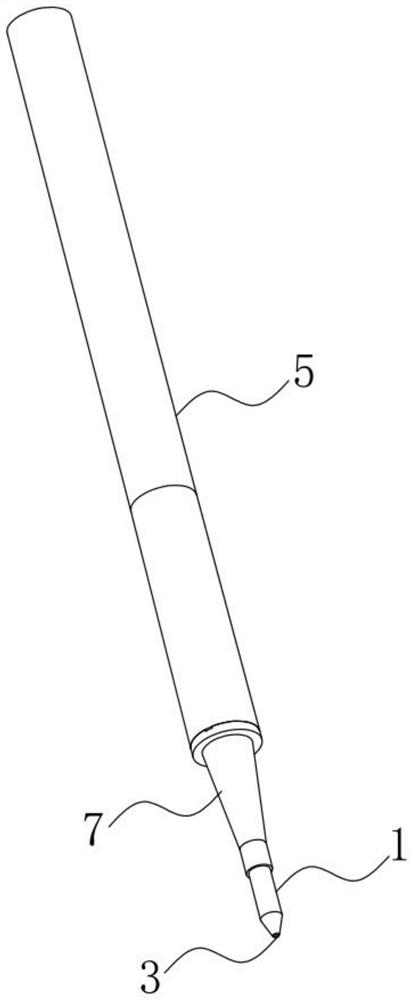

PendingCN114312102ASimple structural designEasy to assembleBall-point pensEngineeringMechanical engineering

The invention discloses a direct liquid type refill capable of being used for a pressing writing pen, which comprises a refill assembly, a pen point arranged at one end of the refill assembly and a water leading refill with elastic deformation capability, and an ink flowing channel and a ball component positioned at the tail end of the ink flowing channel are arranged in the pen point. The ink guiding core is arranged in the pen refill assembly in a penetrating mode, one end of the ink guiding core extends into the ink flowing channel and abuts against the ball bead component, so that the ink guiding core is compressed to generate elastic deformation, and elastic force is applied to the ball bead component to enable the ball bead component to abut against the inner wall of the tail end of the ink flowing channel tightly. According to the direct liquid type pen refill capable of being used for the pressing writing pen, the water leading refill with the elastic deformation capacity is adopted, the ball component is driven to abut against the inner wall of the pen point bowl opening on the pen point under the elastic force effect of the water leading refill to achieve self-sealing, ink leakage and ink drying are prevented when writing is not carried out, and the direct liquid type pen refill can be suitable for various types of writing pens such as the pressing type writing pen.

Owner:宁波华丰文具有限公司

Electronic product shell, electronic product cover spraying method

ActiveCN110813587BAchieve full coverage sprayingSmall film thickness errorLiquid surface applicatorsCoatingsBatch operationMechanical engineering

The present disclosure relates to a spraying method for an electronic product casing and an electronic product cover, the spraying method comprising: fixing a spraying device; conveying the electronic product cover below the spraying device along the length direction of the electronic product cover; and using The spraying equipment sprays the upper surface of the conveyed electronic product cover, wherein, in the step of using the spraying equipment to spray the upper surface of the conveyed electronic product cover, the spraying The effective spraying width of the equipment is greater than the width of the electronic product cover. In this way, the spraying equipment is fixed, and the electronic product cover plate is sent to the bottom of the spraying equipment for spraying operation, which can realize assembly line and batch operation, and improve the spraying efficiency. The effective spraying width of the spraying equipment is much larger than that of the electronic product cover plate. Width, the effective area of ink atomization is all coated on the cover plate of electronic products, realizing full-coverage spraying on the cover plate of electronic products.

Owner:BYD CO LTD

Inorganic nanomaterial printing ink and its preparation method and application

Owner:TCL CORPORATION

High-performance and easy-erasing ink and preparation method thereof

InactiveCN103992693AImprove dispersion stabilityLow viscosityChemical industryInksPolyvinyl alcoholChemical products

The invention relates to a high-performance and easy-erasing ink and a preparation method thereof, and belongs to the technical field of chemical product preparation. The ink comprises, by weight, 2.0-5.0 parts of pigment, 3.0-7.0 parts of film forming agent, 2.0-6.0 parts of a dispersing agent, 4.0-8.0 parts of a moisturizing agent, 2.0-5.0 parts of xanthan gum, 1.0-3.0 parts of sodium chloride, 2.0-5.0 parts of polyvinyl alcohol, 1.0-3.0 parts of sacha inchi oil and 83.0-58.0 parts of a solvent. The preparation steps as below: first adding the solvent into a pre-dispersion pot, successively adding with stirring the dispersing agent, film forming agent, moisturizing agent, xanthan gum, chloride sodium, polyvinyl alcohol and sacha inchi oil according to the formula ratio, until complete homogeneous dissolution, and finally adding the pigment; and fully stirring for mixing, and then conducting micro-grinding for 2-8 h, so that the pigment particle diameter reaches a certain size, stopping grinding, and discharging. The ink prepared by the invention has bright color, low viscosity, even ink outflow, fluent writing, no adhesion to the board, stable quality and good performance, and is very easy to wipe, energy-saving and environment-friendly.

Owner:胡志新

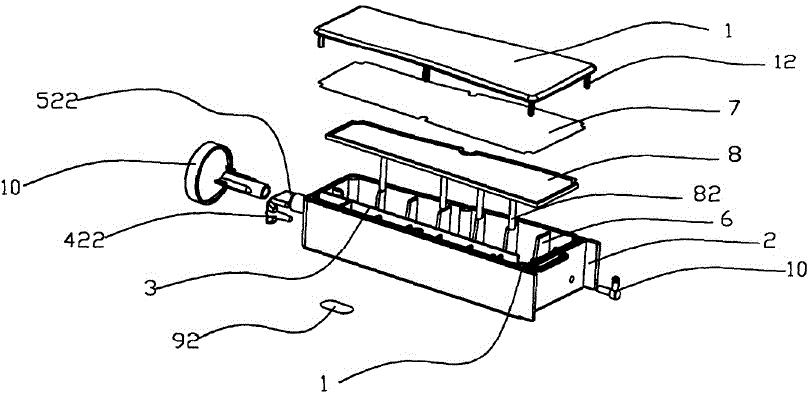

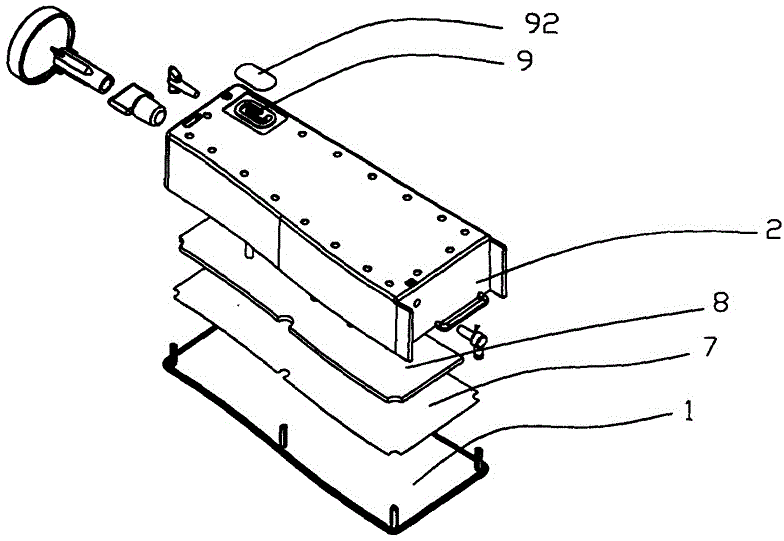

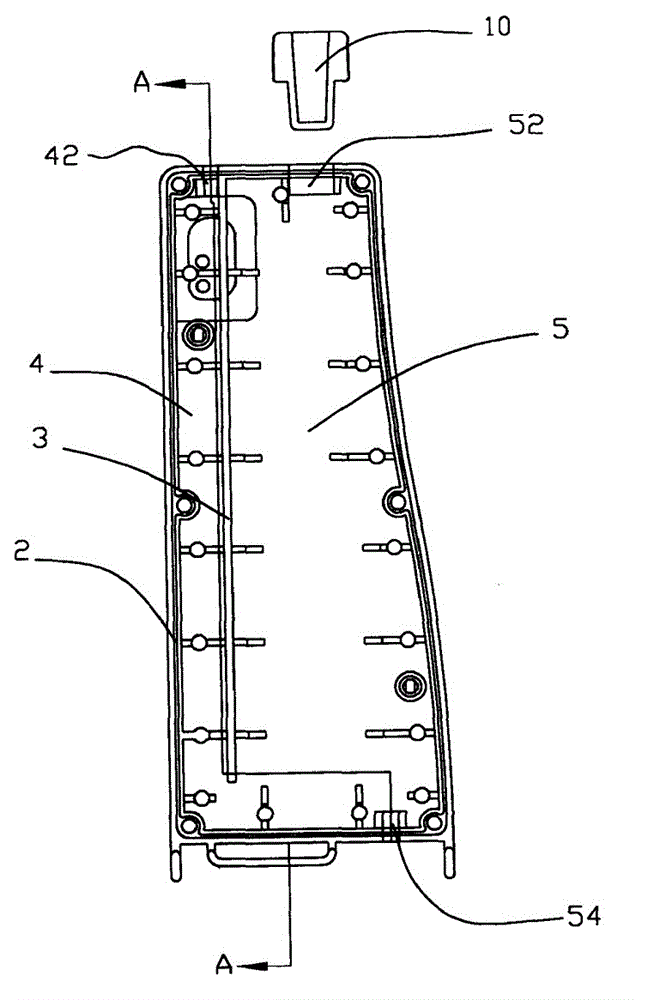

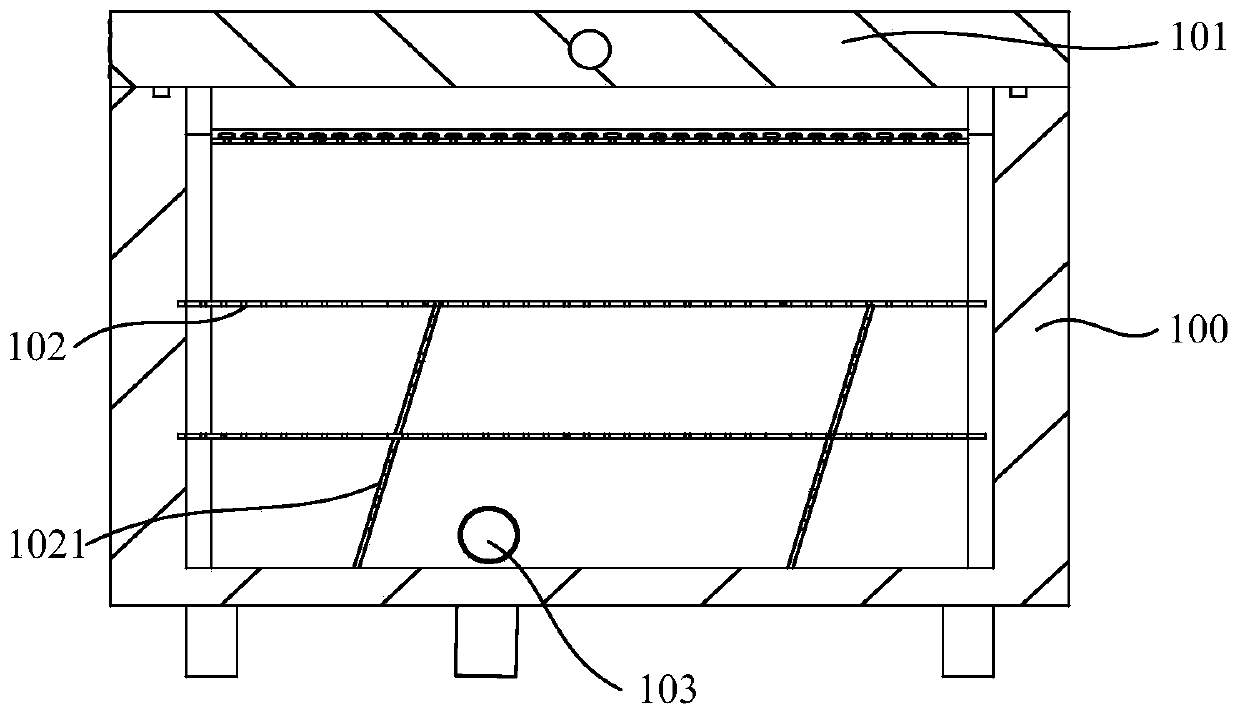

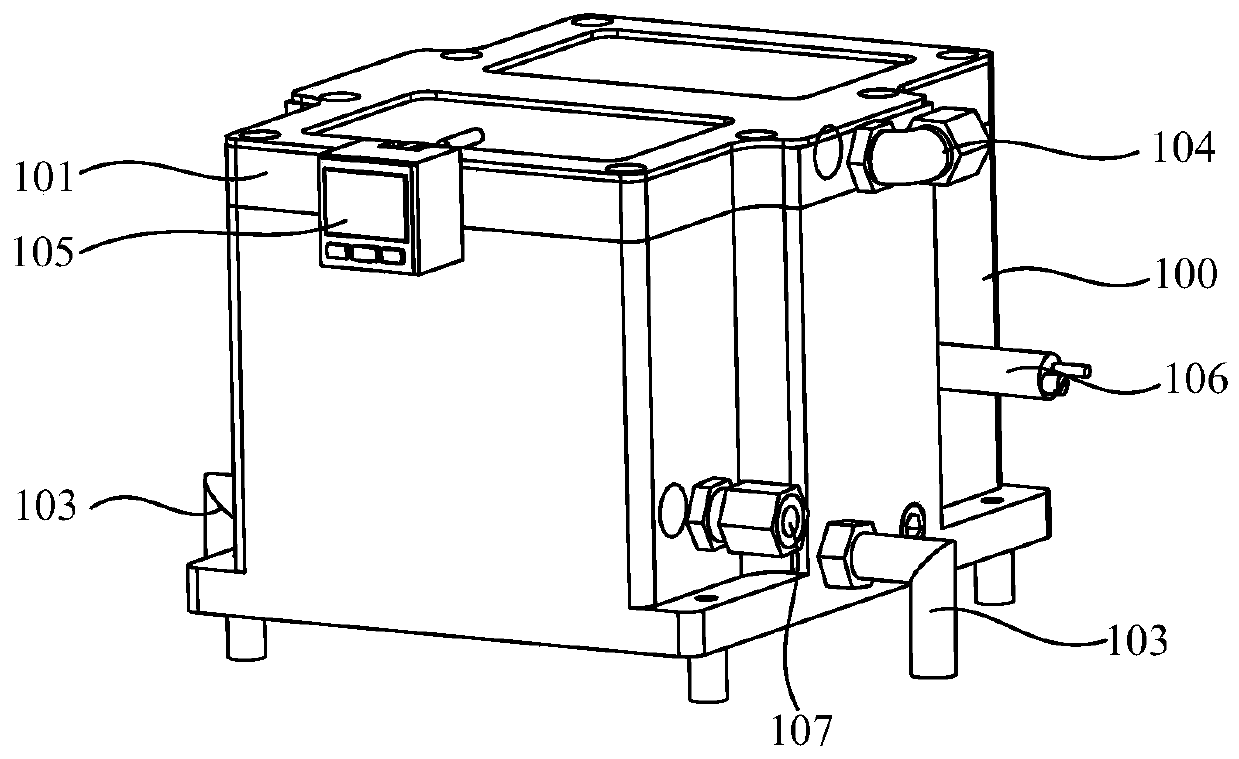

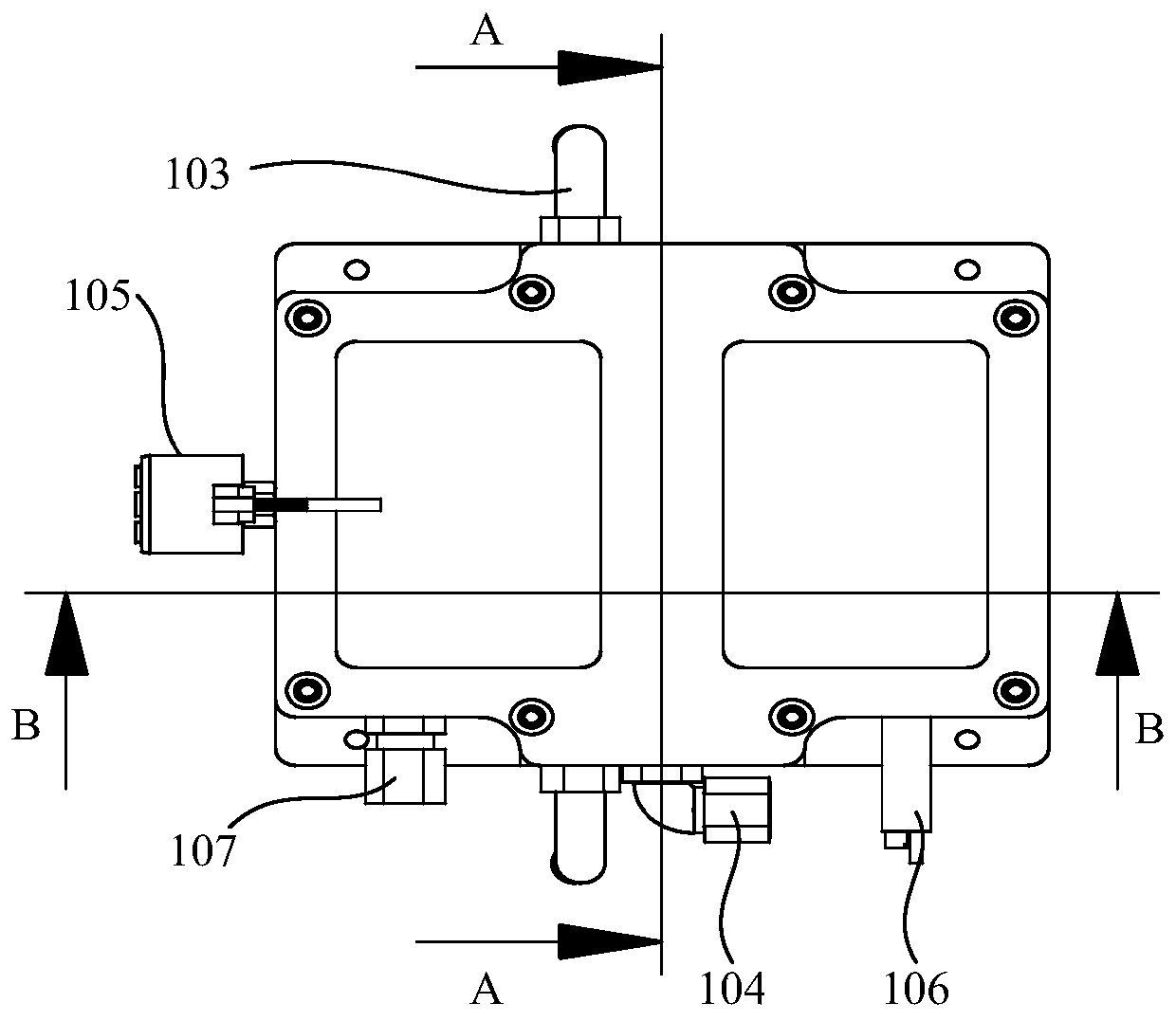

Ink box and sand mold 3D printing machine

PendingCN110039634AHigh outputSurgeAdditive manufacturing apparatusFoundry mouldsEngineering3d printer

The invention provides an ink box and a sand mold 3D printing machine, and relates to the technical field of printing. The ink box comprises a box body with a cavity and partitions arranged in the cavity. An opening communicating with the cavity is formed in one end of the box body, and a cover plate covers the opening. An ink output port is further formed in the side wall of the box body and usedfor being externally connected with a printing sprayer. The cavity is divided into multiple sub-cavities through the partitions, and through holes for enabling the adjacent sub-cavities to communicate are formed in the partitions. Wen the ink box shakes, ink shakes along with the ink box, as the cavity is divided into the multiple sub-cavities through the partitions, when the ink contained in thesub-cavities passes through the partitions in the shaking process, the partitions can have the effect of restraining shaking of the ink, the effect that shaking of the ink in each sub-cavity is restrained by each sub-cavity is formed, and then the situation that the ink in the cavity suffers from wide-range surging is restrained on the whole.

Owner:NINGXIA KOCEL MOLD

Printing ink using inorganic nanometer material and preparation method and application thereof

InactiveCN109810571AImprove flame retardant performanceLow global warming potentialInksArylOrganic solvent

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing ester organic solvent, wherein the structure of the fluorine-containing ester organic solvent is shown in a formula IV, namely (Rb')n'-(Rfb)n-O-(Rfa)m-(Ra')m'; in the formula IV, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Ra' and Rb' are independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1,and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:TCL CORPORATION

Pressing direct liquid type double-ball refill

PendingCN114801548APrevent drynessWith elastic deformation abilityBall-point pensStructural engineeringMechanical engineering

The invention discloses a pressing direct liquid type double-ball pen refill which comprises a pen refill assembly, a pen point arranged at one end of the pen refill assembly, a first water guiding refill and a second water guiding refill capable of conducting elastic deformation. A first ball and a second ball which abut against each other are arranged at the position, located at the tail end of the ink flowing channel, of the pen point. The first ink guiding core is movably arranged in the ink flowing channel, and one end of the first ink guiding core abuts against the second ball. The second water guide core is fixedly inserted into the pen core assembly, and one end of the second water guide core elastically abuts against the other end of the first water guide core so that elastic force facing the second ball can be applied to the first water guide core. According to the pressing direct-liquid type double-ball-bead pen refill, elastic force is applied to the first ball bead through the second water guiding core to achieve sealing, the good ink leakage prevention effect is achieved, meanwhile, the double-ball-bead structural design is adopted, friction force of the first ball bead is reduced, and writing is smoother.

Owner:宁波华丰文具有限公司

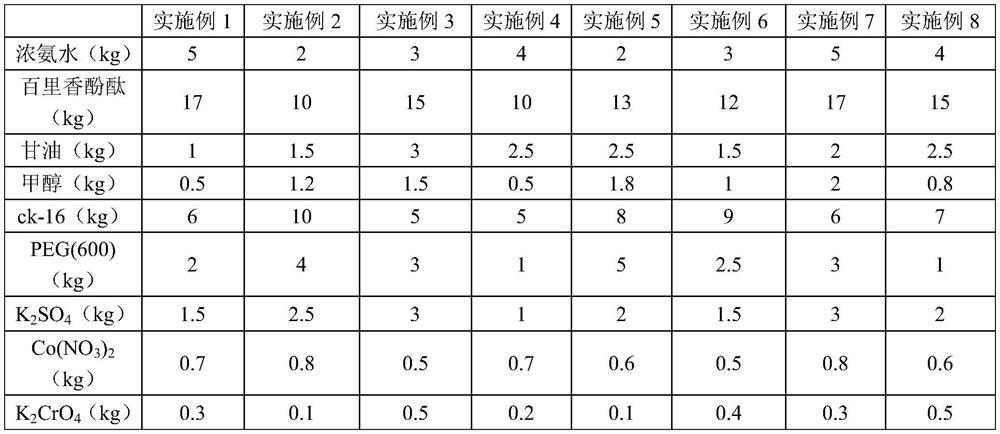

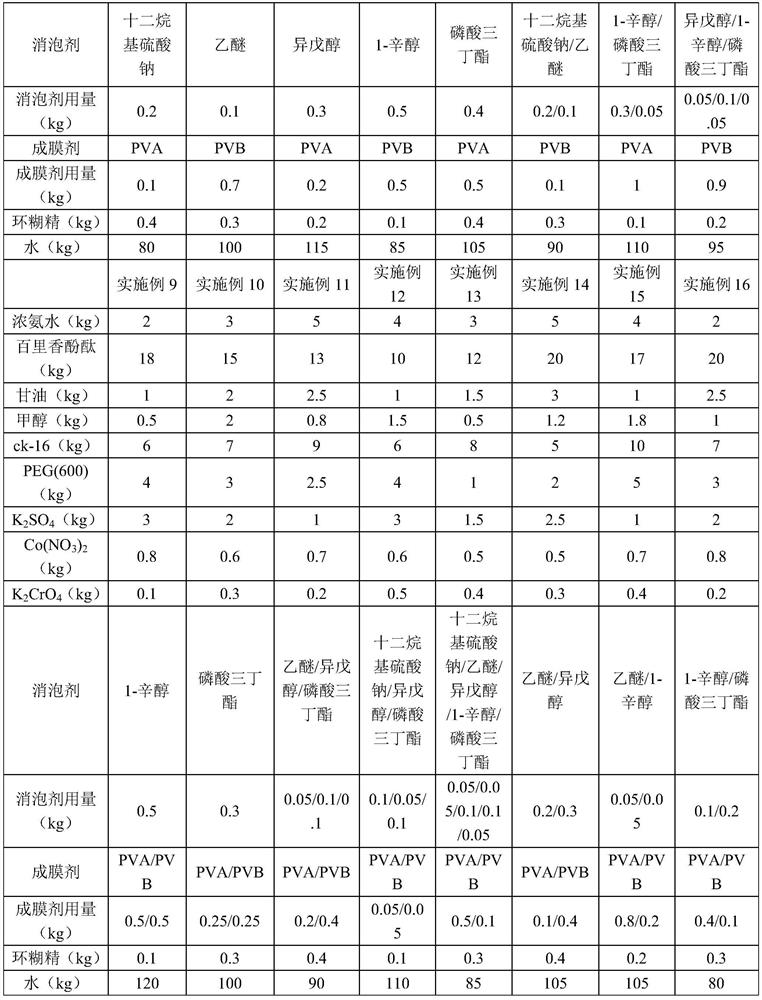

A self-dissipating ink and its preparation method

The invention discloses an ink that can dissipate automatically. The composition includes 2-5 parts of lye, 10-20 parts of phenolphthalein, 1-3 parts of glycerin, 0.5-2 parts of methanol, 3,3-bis (N-octyl-2-methylindole) phthalide 5-10 parts, PEG600 1-5 parts, K 2 SO 4 1 to 3 parts, Co(NO 3 ) 2 0.5~0.8 parts, K 2 CrO 4 0.1-0.5 parts, 0.1-1 parts of film-forming agent, 0.1-0.5 parts of defoamer, 0.1-0.4 parts of cyclodextrin and 80-120 parts of water. The invention also discloses a preparation method of the self-dissipating ink. The self-dissipating ink of the present invention has strong adhesion, uniform ink output, non-diffusion, and can adhere to substrates such as paper, fiber, and plastic; meanwhile, the ink can quickly fade under sunlight, which promotes the adhesion of substrates. Reusable and more environmentally friendly.

Owner:东莞市唐德医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com