Direct liquid type refill capable of being used for pressing writing pen

A direct-liquid writing pen technology, applied in the field of writing pens, can solve the problems that the ink is easy to volatilize and dry up, and the straight-liquid pen core cannot be applied to the push-type writing pen, etc., so as to increase product stability, small friction, and guarantee The effect of the writing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

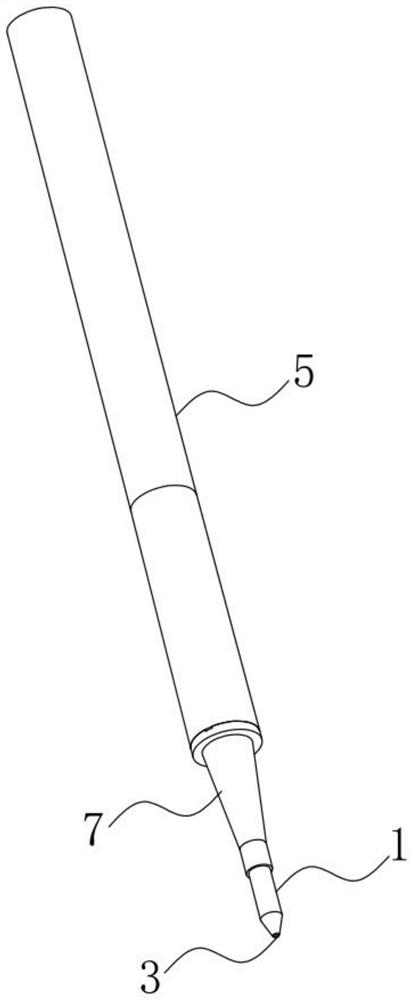

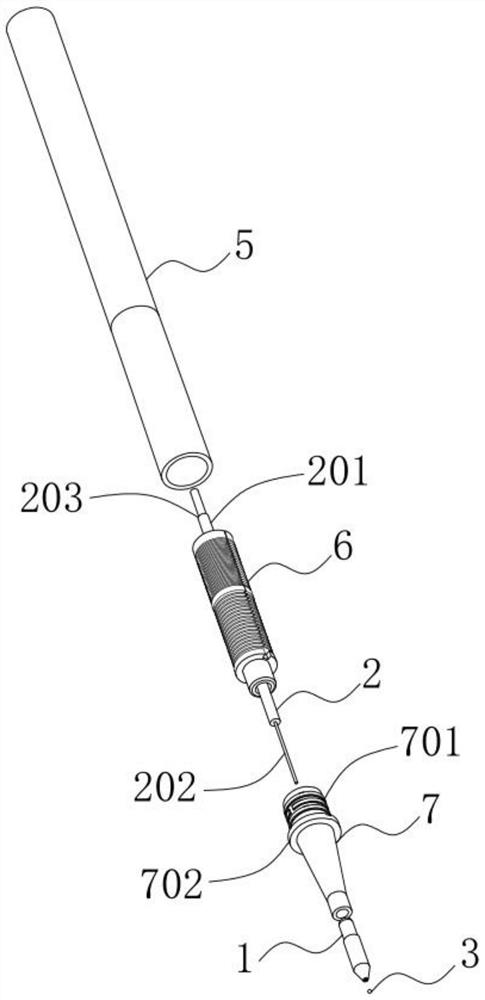

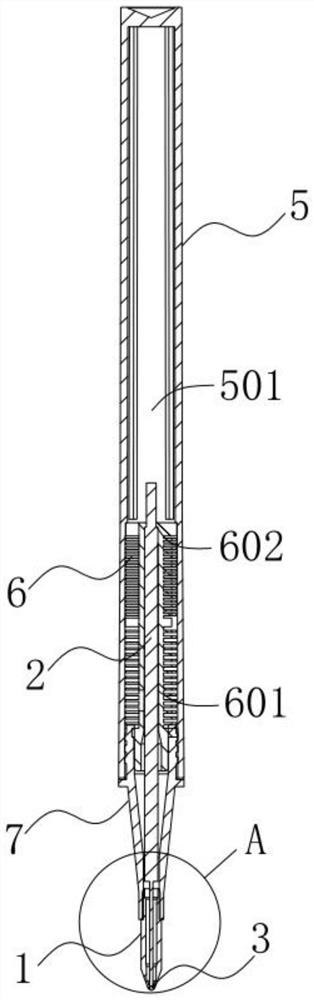

[0043] refer to Figure 1 to Figure 4 , the present invention provides a direct liquid refill for a push writing pen, comprising: a refill assembly, a nib 1 arranged at the lower end of the refill assembly, and a water diversion core 2 with elastic deformation capability. A penetrating ink flow channel 101 is formed inside the pen head 1, and a ball part is provided at the ink flow end of the pen head 1 at the ink flow channel 101. Inner and against the ball part, so that the water guide core 2 is compressed and elastically deformed, so as to exert elastic force on the ball part to make it tightly against the end inner wall of the ink flow channel 101 .

[0044] refer to image 3 and Figure 4 The nib 1 is provided with a nib bowl 102 at the end of its inner ink flow channel 101, the ball part includes a first ball 3, the first ball 3 can be accommodated in the nib bowl 102 up and down and at least partly convex. exposed outside. The water diversion core 2 is a porous fibe...

Embodiment 2

[0057] refer to Figure 10 The difference between this embodiment and the first embodiment is that the ball component includes a first ball 3 and a second ball 4 , and the second ball 4 is located above the first ball 3 and abuts against each other. The lower end of the water diversion core 2 elastically leans against the second ball 4 , and the second ball 4 drives the first ball 3 to seal against the inner wall of the nib mouth 102 . In this application, by adopting the double-ball structure design, the first ball 3 is subjected to less frictional force, so that the ink discharge is uniform and the writing is smoother.

[0058] refer to Figure 10 and Figure 11 , A ball seat portion 103 is provided in the ink flow channel 101 close to the nib bowl mouth 102 , and the second ball 4 is limited on the ball seat portion 103 . Several lower ink grooves 104 are arranged along the inner wall between the ball seat portion 103 and the nib bowl mouth 102 , so that the ink in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com