A kind of water-based nano pigment type neutral pen ink and preparation method thereof

A gel pen ink, nano-pigment technology, applied in inks, household appliances, applications, etc., can solve the problems of high ink viscosity and poor stability, and achieve the effects of good ink stability, stable quality and strong water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

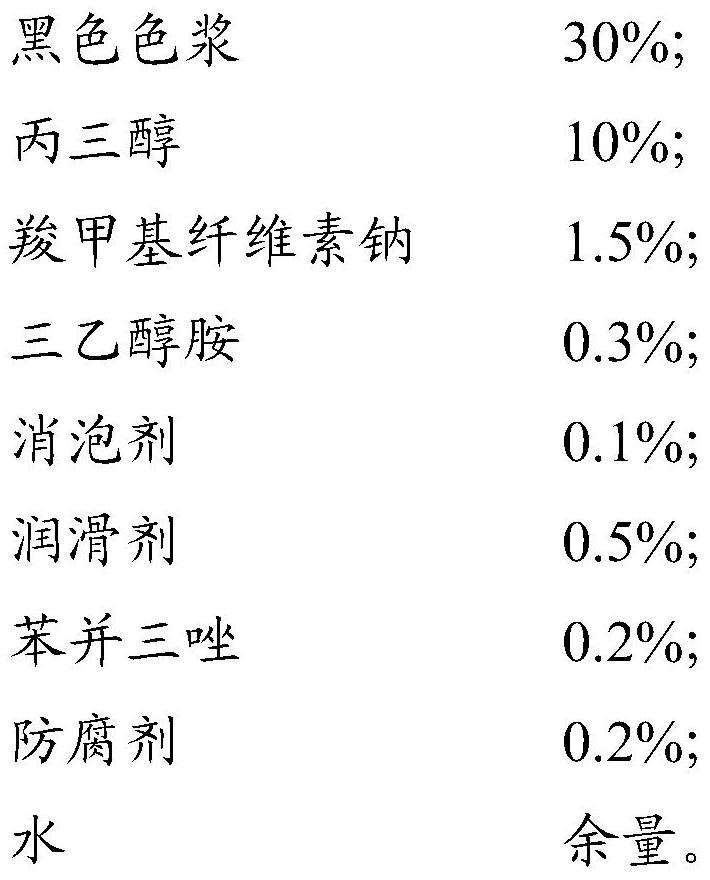

[0027] A carbon black water-based nano-pigment type neutral pen ink, comprising the following components and weight percentages:

[0028]

[0029] Wherein the average particle size of the black color paste is 100nm, mainly comprising the following components and weight percentages:

[0030]

[0031] The preparation method of black color paste comprises the following steps:

[0032] (1) First dissolve the dispersant BYK190 in deionized water, add Degussa 4# carbon black to make it fully wet, then add surfactant PE-100, ethylene glycol and defoamer and stir well;

[0033] (2) According to the weight ratio of the grinding ball and the mixed material obtained in step (1) is 7:3, add it to the sand mill for grinding and dispersing; wherein the particle size of the grinding ball is 0.3um;

[0034] (3) discharge and filter to obtain the black color paste without resin type nanometer.

[0035] The preparation method of the above-mentioned carbon black water-based nano-pigment ...

Embodiment 2

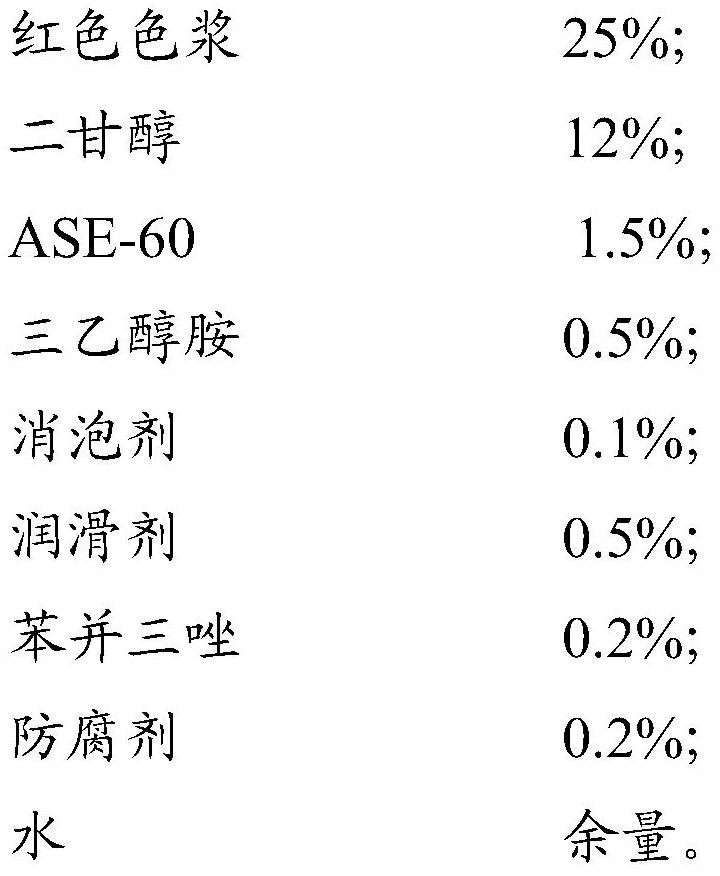

[0037] A kind of red water-based nano-pigment type neutral ink comprises the following components and weight percentages:

[0038]

[0039] Wherein the average particle diameter of black color paste is 250nm, comprises following component and weight percentage:

[0040]

[0041] The preparation method of red color paste comprises the following steps:

[0042] (1) First dissolve the dispersant DEGO740W in deionized water, add PR.254 red to make it fully wet, then add surfactant PE-100, propylene glycol and defoamer and stir well;

[0043] (2) According to the weight ratio of the grinding ball and the mixed material obtained in step (1) is 7:3, add it to the sand mill for grinding and dispersing; wherein the particle size of the grinding ball is 1um;

[0044] (3) discharge and filter to obtain the red color paste without resin type nanometer.

[0045] The preparation method of the above-mentioned red water-based nano-pigment type neutral pen ink is: fully stir and mix the ...

Embodiment 3

[0047] A blue water-based nano-pigment type neutral ink, comprising the following components and weight percentages:

[0048]

[0049] Wherein the average particle size of the blue color paste is 200nm; including the following components and weight percentages:

[0050]

[0051] The preparation method of blue color paste comprises the following steps:

[0052] (1) First dissolve the dispersant BYK190 in deionized water, add phthalocyanine blue BGS to make it fully wet, then add surfactant PE-100, propylene glycol and defoamer and stir well;

[0053] (2) According to the weight ratio of the grinding ball and the mixed material obtained in step (1) is 7:3, add it to the sand mill for grinding and dispersing; wherein the particle size of the grinding ball is 0.5um;

[0054] (3) The discharge is filtered to obtain the blue color paste without resin type nanometer.

[0055] The preparation method of the above-mentioned blue water-based nano-pigment type neutral pen ink is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com