Printer ink box capable of being filled with ink repeatedly

A technology of printers and ink cartridges, applied in printing and other fields, can solve the problems of reducing ink, reducing the efficiency of ink cartridges, and waste of ink, etc., and achieve the effect of continuous ink output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

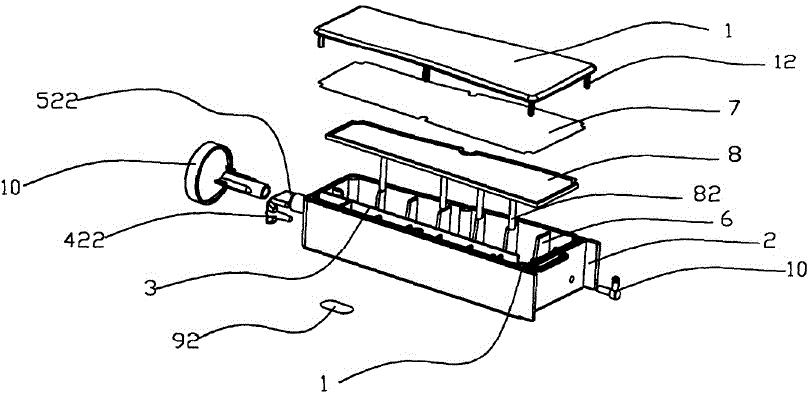

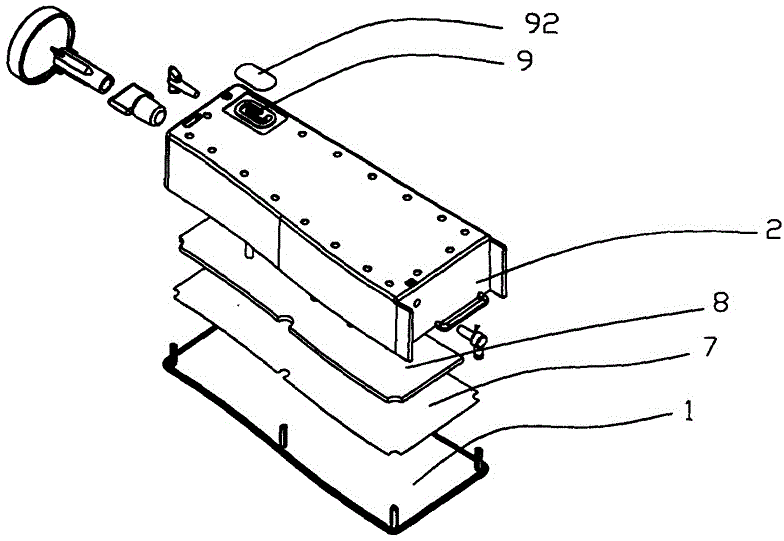

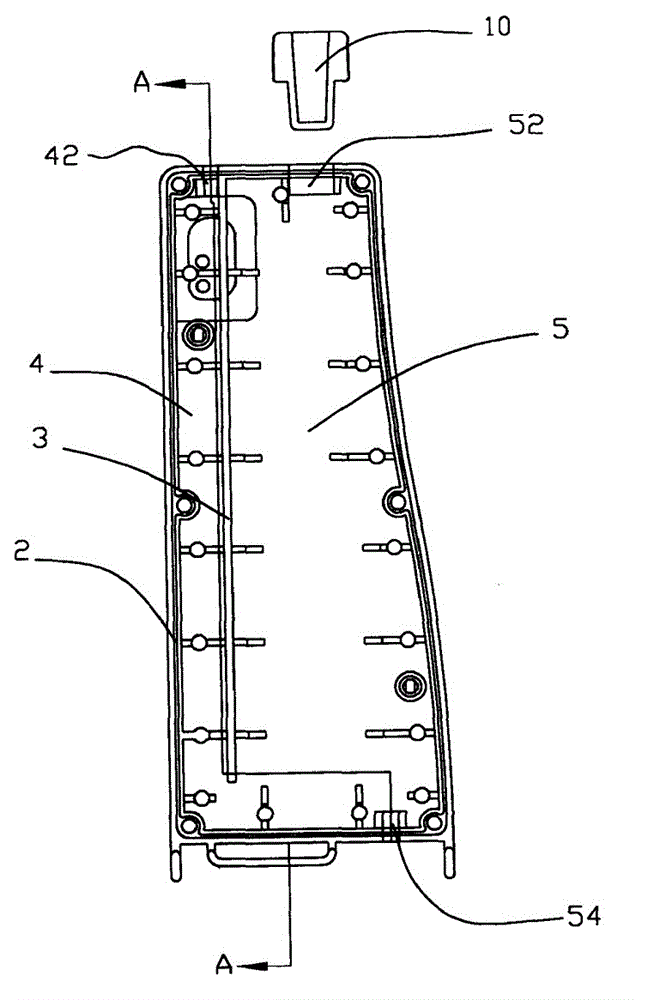

[0014] In order to further illustrate the present invention, further description is given below in conjunction with the accompanying drawings:

[0015] like Figure 1-4 As shown, a printer ink cartridge of the present invention that can be refilled with ink includes a face cover 1 and a bottom box 2 matched with it. The bottom box 2 is provided with a baffle 3, which divides the bottom box cavity into The air cavity 4 and the ink cavity 5 communicate with each other at the bottom, the air hole 42 communicated with the air cavity 4 and the ink filling port 52 communicated with the ink cavity 5 are arranged on the top of the bottom box, and the ink outlet communicated with the ink cavity is arranged at the bottom of the bottom box. 54; On the described face cover 1, the lower ends of the four corners are provided with assembling pins 12, and the corresponding bottom box 2 is provided with assembling holes 22 matching the assembling pins; The partition plate 6, this partition pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com