A self-dissipating ink and its preparation method

An ink, automatic technology, applied in the field of ink, can solve the problems of easy color fading, inability to automatically dissipate, poor ink adhesion, etc., to achieve the effect of simple process, promotion of reusability, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

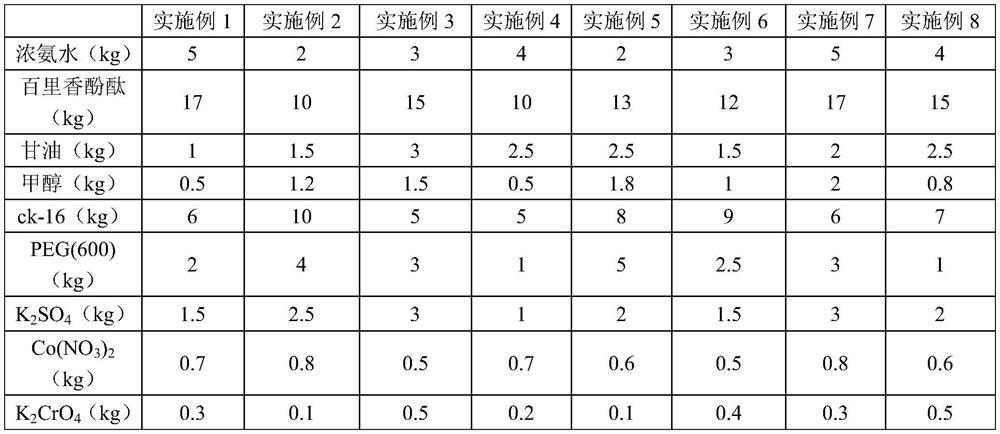

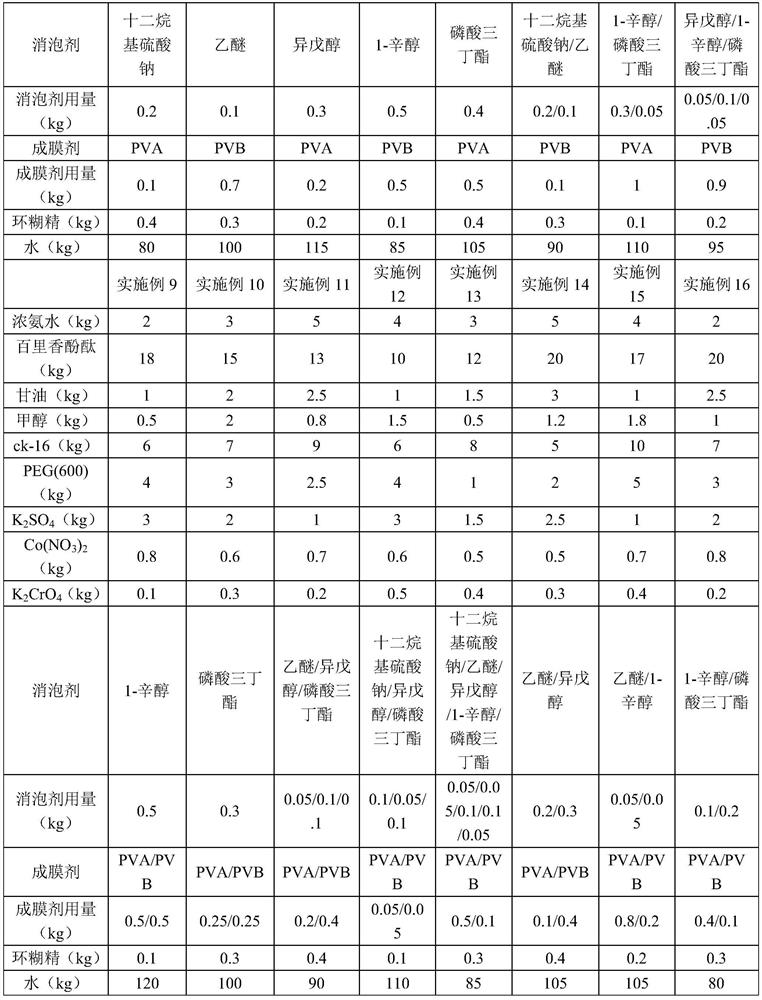

Examples

Embodiment 19

[0044] Preparation of the first mixed solution step: Take 2kg of concentrated ammonia water and add it to 20kg of pure water, let it stand for 2 minutes at room temperature, then add 1kg of PEG (600), stir and mix it for 10 minutes at room temperature, then add 0.1kg of tributyl phosphate and 0.1kg of cyclic Dextrin, stirred and dispersed at 45°C for 0.5h to obtain the first mixed solution.

[0045] Preparation of the second mixed solution step: take 0.5kg of methanol and add it to 20kg of water, then add 1kg of K 2 SO 4 , 0.5kgCo(NO 3 ) 2 and 0.1kgK 2 CrO 4 , stirred at room temperature for 10 minutes, then added 10 kg of thymolphthalein, and stirred and dispersed at 45° C. for 10 minutes.

[0046] Preparation of the third mixed solution step: take 1 kg and add it to 40 kg of water, keep it warm at 45°C for 5 minutes, then add 5 kg of 3,3-bis(N-octyl-2-methylindole) phthalide, 65 Stir at ℃ for 40 minutes, then add 0.05kg of PVA resin and 0.05kg of PVB resin, stir and di...

Embodiment 20

[0049] Preparation of the first mixed solution step: Take 3kg of concentrated ammonia water and add it to 25kg of pure water, let it stand at room temperature for 3 minutes, then add 3kg of PEG (600), stir and mix at room temperature for 18 minutes, then add 0.3kg of tributyl phosphate and 0.3kg of cyclohexanol to it Dextrin, stirred and dispersed at 58°C for 1 hour to obtain the first mixed solution.

[0050] Preparation of the second mixed solution step: get 2kg of methanol and add it to 25kg of water, then add 2kg of K 2 SO 4 , 0.6kgCo(NO 3 ) 2 and 0.3kgK 2 CrO 4 , stirred at room temperature for 20 minutes, then added 15kg of thymolphthalein, stirred and dispersed at 50°C for 20 minutes.

[0051] Preparation of the third mixed solution step: take 2kg and add it to 50kg of water, keep it warm at 55°C for 5 minutes, then add 7kg of 3,3-bis(N-octyl-2-methylindole)phthalide, 70 Stir at ℃ for 60 minutes, then add 0.25kg of PVA resin and 0.25kg of PVB resin, stir and dispe...

Embodiment 21

[0054] Preparation of the first mixed solution step: Take 5kg of concentrated ammonia water and add it to 30kg of water, let stand at room temperature for 5 minutes, then add 5kg of PEG (600), stir and mix at room temperature for 30 minutes, then add 0.5kg of tributyl phosphate and 0.4kg of cyclopaste Refined, stirred and dispersed at 65°C for 1.5h to obtain the first mixed solution.

[0055] Preparation of the second mixed solution step: take 1.5kg of methanol and add it to 30kg of water, then add 3kg of K 2 SO 4 , 0.8kgCo(NO 3 ) 2 and 0.5kgK 2 CrO 4 , stirred at room temperature for 30 minutes, then added 20 kg of thymolphthalein, stirred and dispersed at 55° C. for 30 minutes.

[0056] Preparation of the third mixed solution step: take 3kg of glycerin and add it to 60kg of water, keep it warm at 65°C for 5 minutes, then add 10kg of 3,3-bis(N-octyl-2-methylindole)phthalide to it, Stir at 80°C for 80min, then add 0.5kg of PVA resin and 0.5kg of PVB resin, stir and dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com