GMT sheet production system for teaching experiments

A technology for production systems and experiments, applied to teaching models, educational tools, instruments, etc., can solve problems such as unfavorable teaching of new materials and product experiments, single design and application functions of composite material equipment, uneven heating of materials, etc. Flexibility, improved impregnation effect, reduced porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

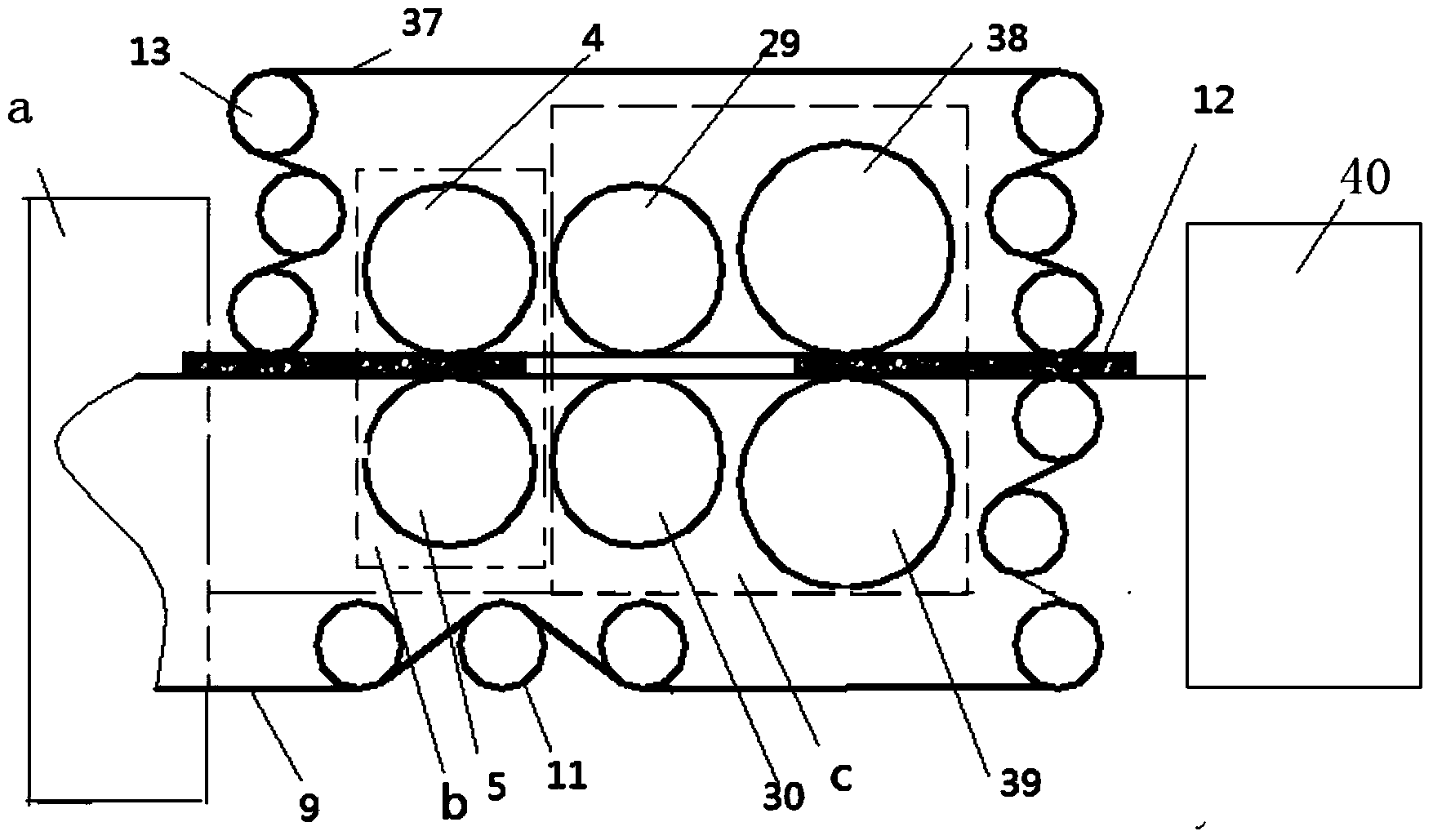

[0082] Such as figure 1 As shown, a GMT sheet production system for teaching experiments, including a transmission system with a lower conveyor belt 9, and a heating and baking system, a heating and dipping system, and a cooling and setting system sequentially connected through the lower conveyor belt 9;

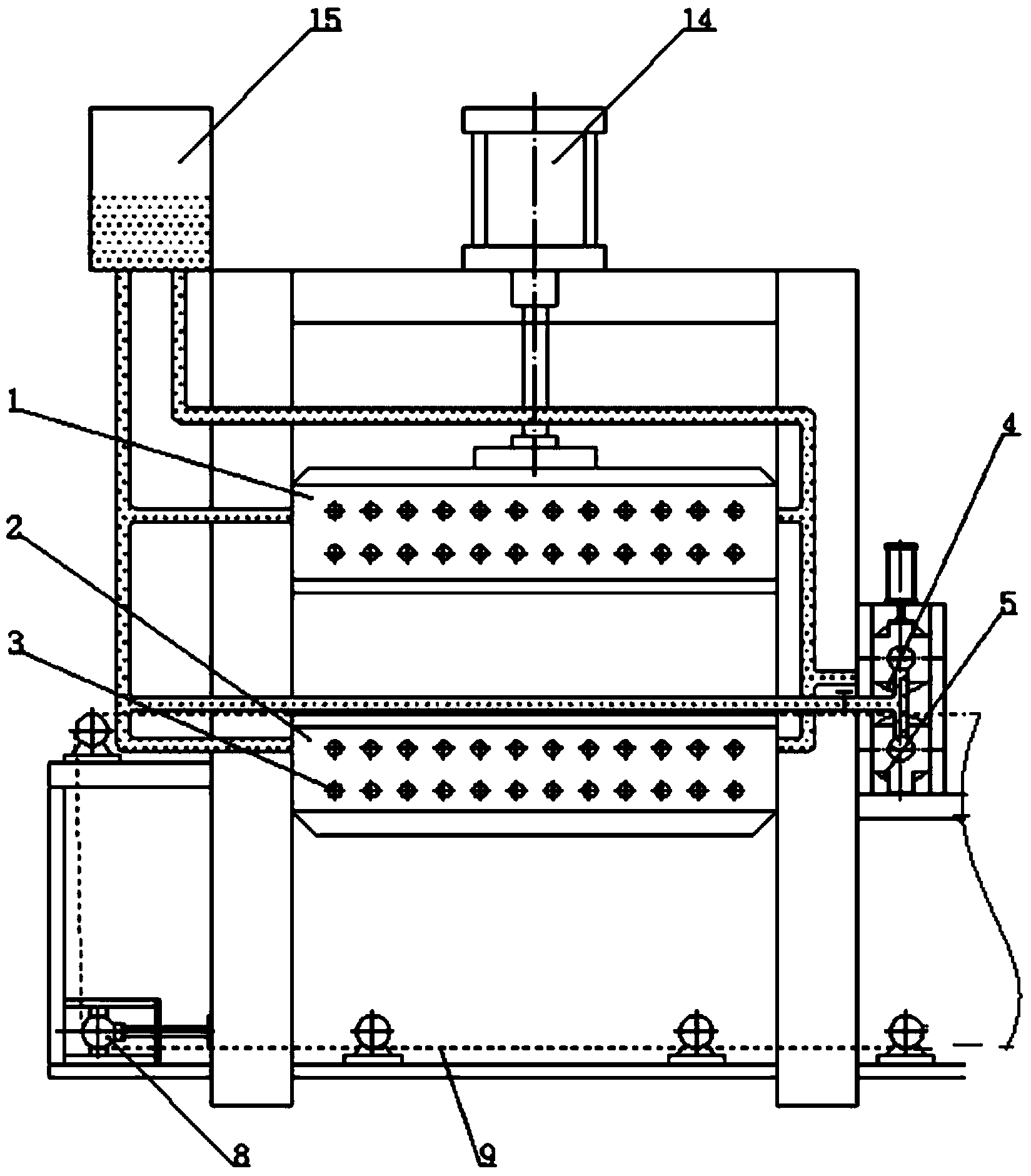

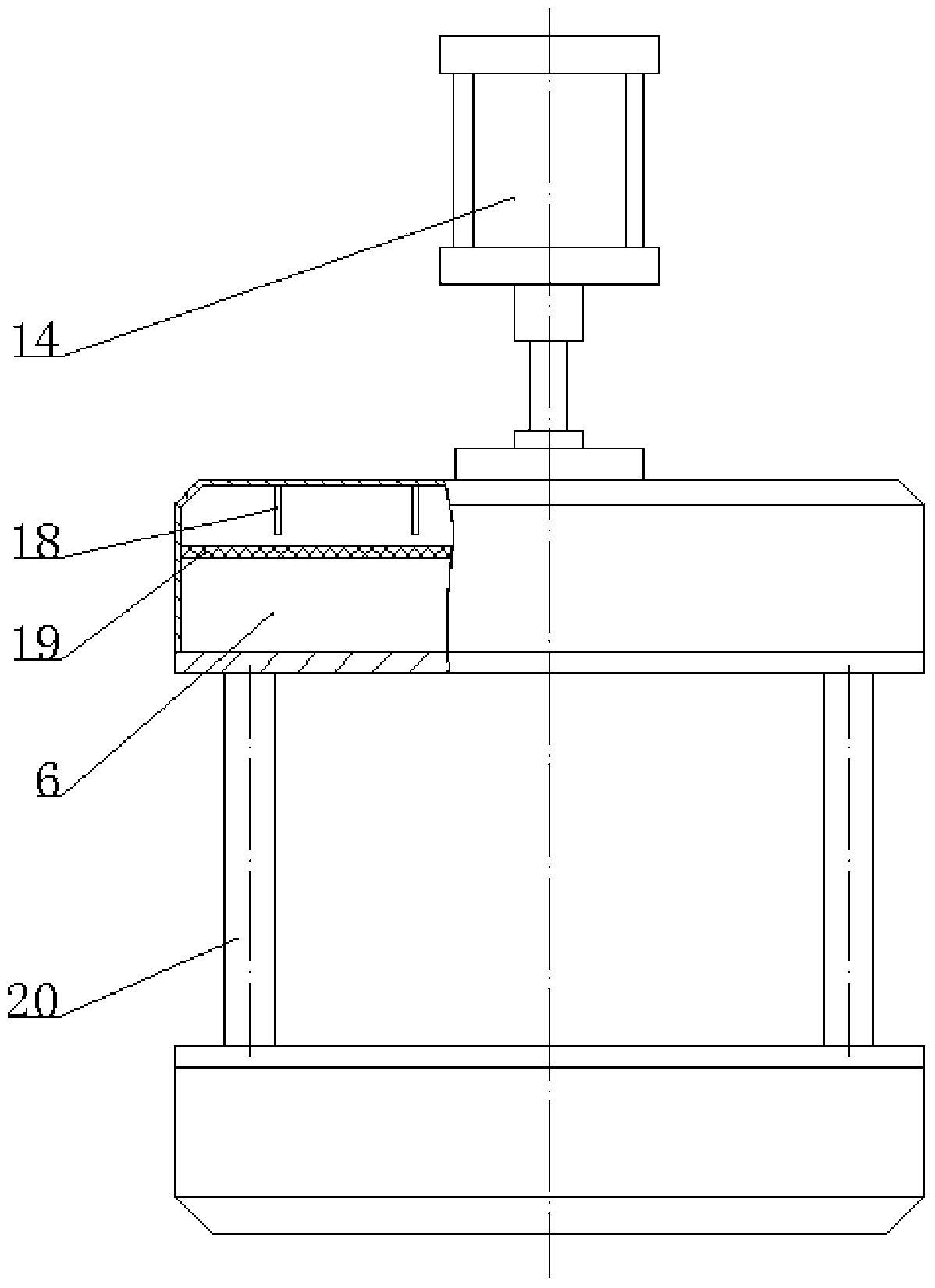

[0083] Such as figure 2 As shown, the adding and baking system includes a heating oil tank 15, a heating platen combination consisting of an upper heating platen 1 and a lower heating platen 2; a heat conduction oil cavity 6 is provided inside the upper heating platen 1 and the lower heating platen 2; A plurality of electric heating tubes 3 are installed inside the upper heating platen 1 and the lower heating platen 2; the lower conveyor belt 9 passes between the upper heating platen 1 and the lower heating platen 2;

[0084] Such as figure 1 , figure 2 As shown, the heating impregnation system includes at least one set of heating impregnation combination consisting of an...

application approach 1

[0094] Application scheme 1: process such as Figure 10 Shown:

[0095] (1) Material preparation: the weight of two sheets is 1000g / m 2 Ordinary PP mould, 1 sheet weighs 840g / m 2 Pure glass fiber felt, the material size is basically the same, and the PP mold, glass fiber felt, and PP mold are laid in order from top to bottom.

[0096] (2) Send the material laid in (1) into the composite material heating equipment. Before that, start the experimental teaching heating equipment, so that the equipment can be heated in advance and reach the preset temperature value (220-230°C) , after the substrate is conveyed to the ideal position of the oven, stop the conveyance, set the heating temperature (220-230°C) and heating time (5-10min), adjust the height of the template on the oven, so that there is a certain reserved space, Start to heat and plasticize the material, and observe the change of its expansion ratio, so that it is convenient to set the ideal heating time, and use the ...

application approach 2

[0102] Application 2: process such as Figure 11 Shown:

[0103] (1) Material preparation: (2+1) GMT sheet, a piece of polyester non-woven fabric, the material size is basically the same, and the GMT sheet and non-woven fabric are laid in order from top to bottom.

[0104] (2) Send the material laid in (1) into the composite material heating equipment. The composite material heating equipment should be started in advance so that the equipment can be heated in advance and reach the preset temperature value (220-230°C). Wait for the plate and After the fabric is delivered to the ideal position of the oven, stop the delivery, set the heating temperature (220-230°C) and heating time (5-10min), adjust the height of the upper template of the oven so that there is a certain reserved space, and start to process The plate is heated and plasticized, and the change of its expansion ratio is observed, so that it is convenient to set the ideal heating time, and the surrounding temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com