Production method for plastic cellular board

A technology of plastic honeycomb panels and plastic honeycombs, applied in the field of plastic honeycomb panels, can solve the problems of limited product thickness, inability to be densely packed, and non-transparent honeycomb holes, and achieve the effects of simplifying production processes, improving production efficiency, and being flexible and convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

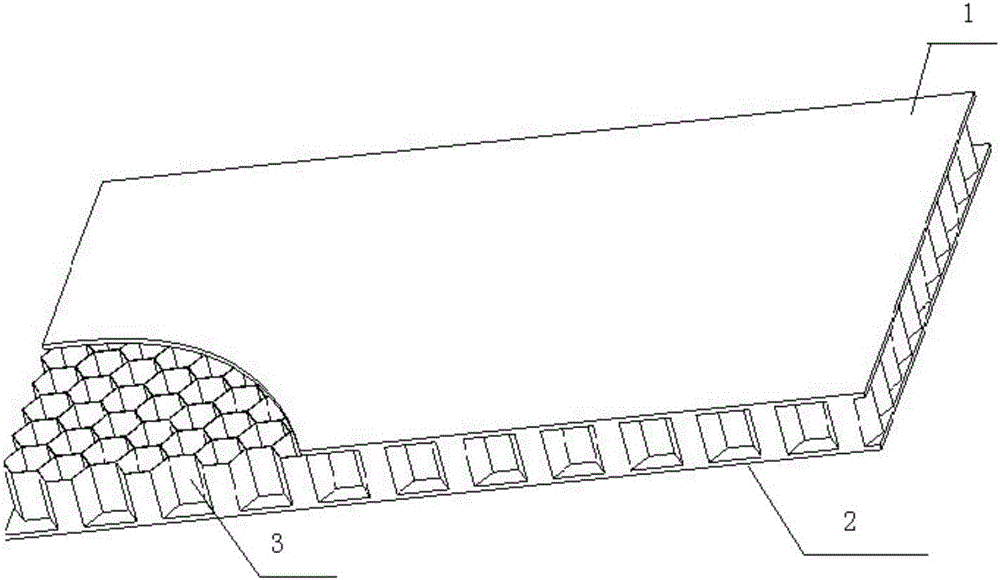

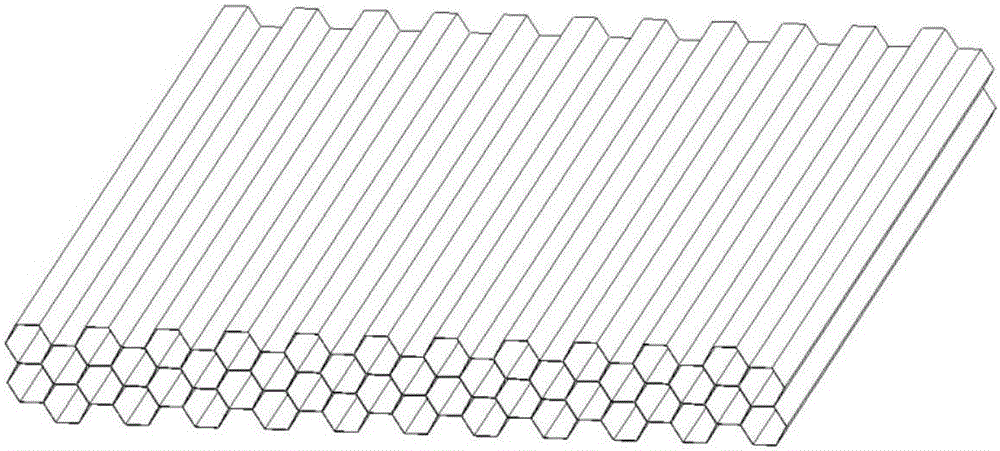

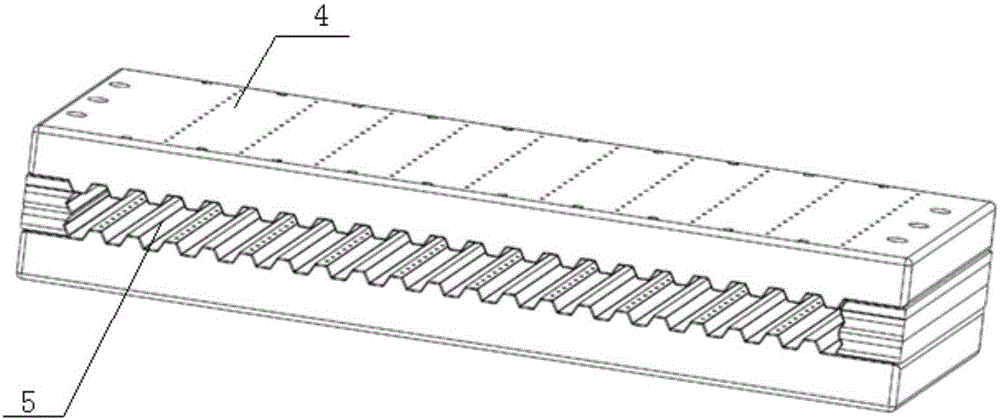

[0045] see Figure 1 to Figure 7 , a production method of a plastic honeycomb panel, the plastic honeycomb panel such as figure 1 Shown: including the upper panel 1 and the lower panel 3, and the plastic honeycomb core 2 between the upper panel 1 and the lower panel 3; the two ends of the plastic honeycomb core 2 are glued between the upper panel 1 and the lower panel 3 Connect; The production method of this plastic honeycomb panel comprises the steps:

[0046] Step 101, the extruder extrudes the plastic honeycomb core raw material through the extrusion die; this process is a continuous extrusion process, that is, as long as the liquid raw material is sufficient, the extruder can continuously extrude the plastic honeycomb core raw material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com