Cooling tank

A technology for cooling water tanks and water tanks, applied in the field of cooling water tanks, which can solve problems such as unfavorable drying of reinforced composite material strips, difficult adjustment of walking distance, waste of clean water resources, etc., and achieve the effect of saving clean cooling water sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

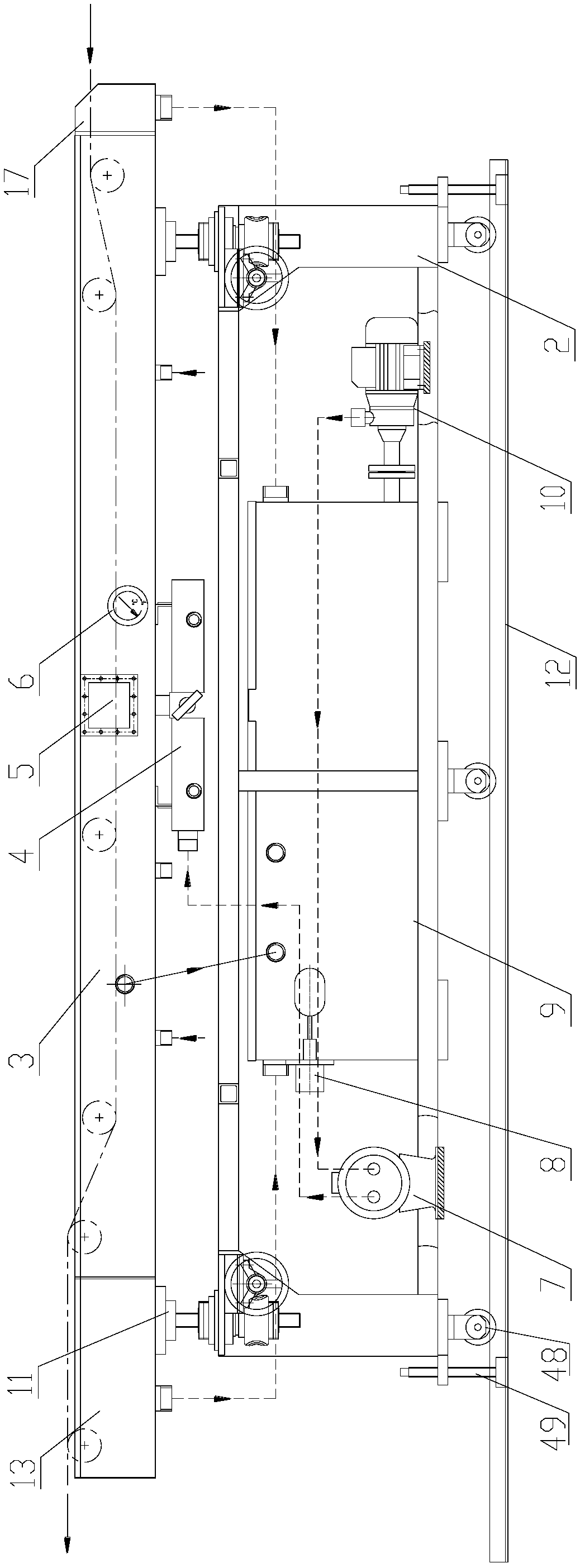

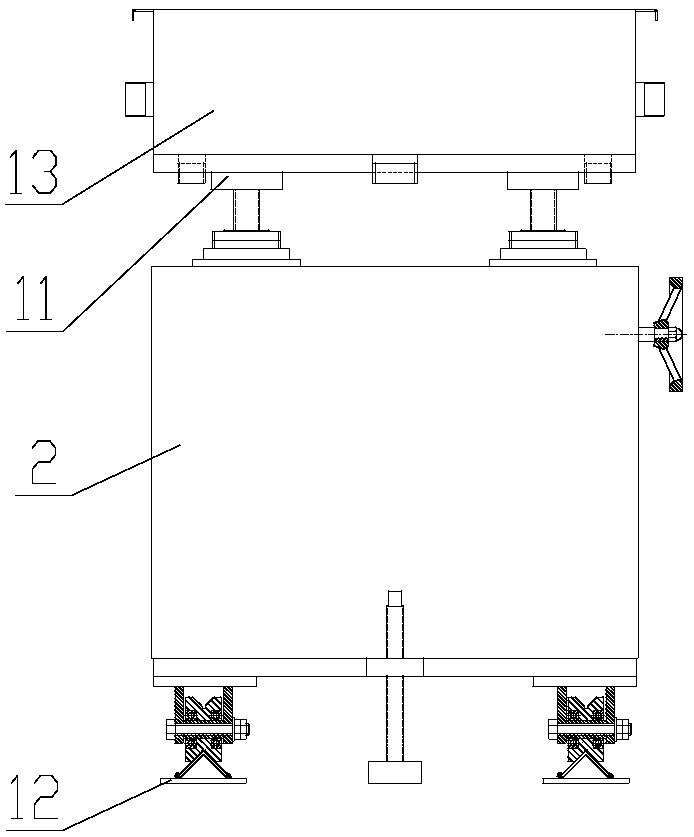

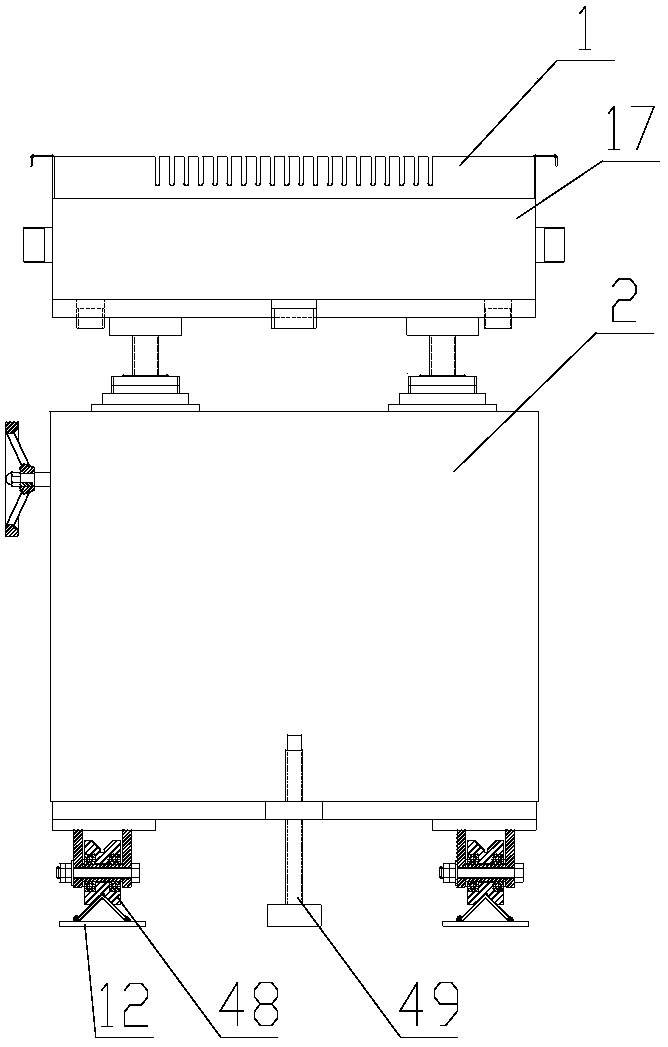

[0038] The present invention will be further explained below in conjunction with the accompanying drawings.

[0039] Such as Figures 1 to 3 As shown, a cooling water tank of the present invention includes an underframe composition 2 , a water tank composition 3 and a guide rail composition 12 . The lower part of the chassis composition 2 is provided with a pulley 48, and the pulley 48 can slide on the guide rail composition 12, so that the cooling water tank can move back and forth as a whole. There are bolt installation positioning holes matched with the adjusting bolt 49, and the base frame composition 2 and the guide rail composition 12 can be relatively fixed by the adjusting bolt 49, so as to stabilize the working position of the cooling water tank.

[0040] Such as figure 1 , 5 As shown in and 6, the top of the chassis composition 2 is provided with a height-adjustable up and down displacement device 11. The up and down displacement device 11 includes a worm spindle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com