Machining extrusion device for mine

A technology of mechanical processing and extrusion devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of the next extrusion processing, cumbersome operation, and lower product precision, so as to achieve tight fit between pick-and-place and fixation , Improve safety performance and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

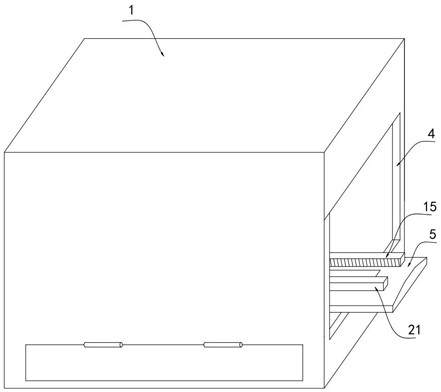

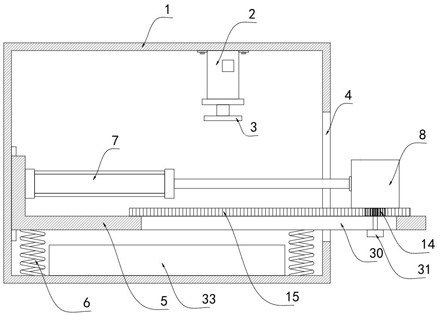

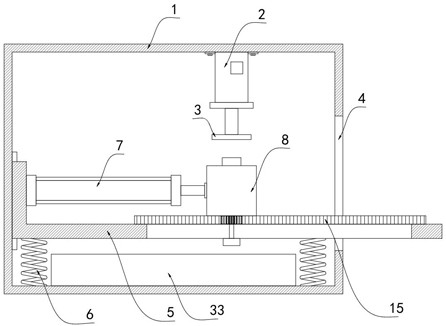

[0033] Such as Figure 1-8 As shown, a mining mechanical processing extrusion device includes a box body 1, which is characterized in that a hydraulic cylinder 2 is fixedly installed on the inner top surface of the box body 1, and an extrusion plate 3 is fixedly installed at the output end of the hydraulic cylinder 2. The extruding plate 3 can be raised and lowered under the drive of the hydraulic cylinder 2 to extrude the parts. There is an opening 4 on the side wall of the box body 1. A horizontal working plate 5 is arranged at the opening 4. One end of the working plate 5 slides Connected to the inner side wall of the box body 1, the other end extends out of the opening 4, the bottom of the working plate 5 is elastically connected to the bottom surface of the box body 1 through the supporting spring 6, and the supporting spring 6 shrinks when the working plate 5 is pressed, and The working plate 5 produces an upward elastic force, which can improve the extrusion effect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com