Chocolate ball auto-forming production apparatus

A technology of automatic molding and production equipment, applied in cocoa, food science, application, etc., can solve the problems of easy deformation, high production cost, long production cycle of chocolate, etc., and achieve the effect of rapid cooling and shaping, and increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

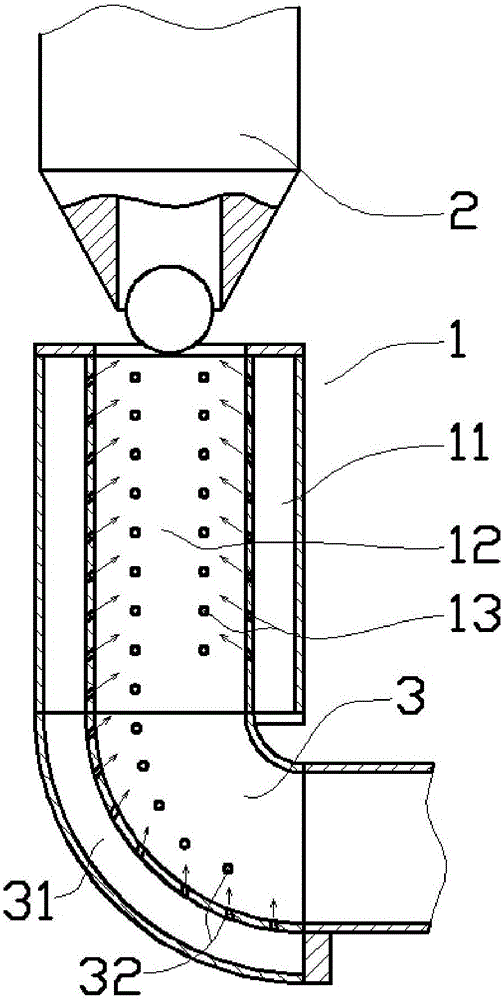

[0014] Such as figure 1 As shown in the embodiment, the spherical chocolate automatic molding production device includes a molding module 1, an injection head 2, and a discharge module 3. The molding module 1 is designed with a vertical annular airflow chamber 11, and the airflow chamber The middle of 11 is designed with the feeding channel 12 of vertical cylindrical cavity, and the cleaning air flow that pressure is higher than the air pressure in feeding channel 12 is passed into in described air flow cavity 11, and the annular wall of described feeding channel 12 is evenly distributed There is an airflow hole 13 communicated with the airflow chamber 11, and the pressure gas fed into the airflow chamber 11 is at a relatively low temperature, which can solidify the chocolate. Under the action of the pressure difference, the gas flow hole 13 through which the gas in the gas flow cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com