Sheet metal stamping device

A stamping device and metal plate technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of reduced precision, plastic deformation, time-consuming and labor-intensive of sheet metal parts, and achieve reduced resilience, enhanced stability, Anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

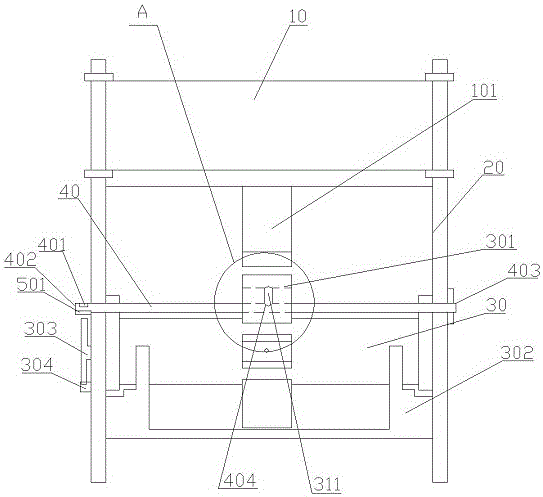

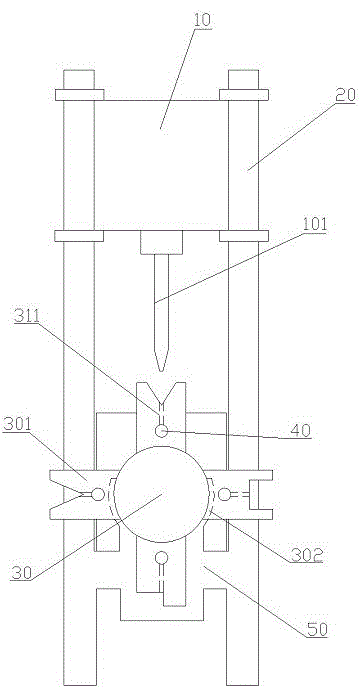

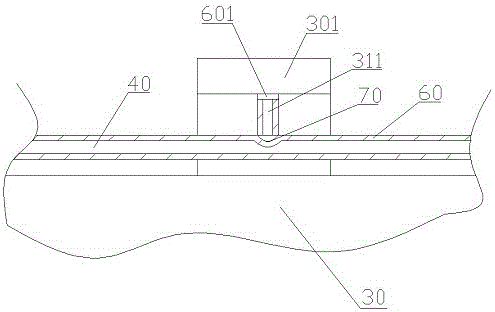

[0017] The reference signs in the drawings of the description include: hydraulic table 10, upper mold 101, frame 20, rotating shaft 30, lower mold 301, first through hole 311, fixing clip 302, handle 303, buckle 304 for fixing the handle, limit Position rod 40, laser generator 401, water inlet hole 402, water outlet hole 403, second through hole 404, machine platform 50, limit block 501, glass steel pipe 60, glass steel plate 601, and seal 70.

[0018] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a stamping device for sheet metal parts, including a hydraulic table 10 , a frame 20 , a machine table 50 , a hollow limit rod 40 and a fixing clip 302 sequentially connected from top to bottom. The upper end of the frame 20 is slidingly connected to the hydraulic table 10, the lower end of the frame 20 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com