Fan Blade Forming Mold

A technology of fan blades and forming molds, which is applied in the field of injection molds, can solve problems such as inconvenient heat dissipation and slow fan blade shaping speed, and achieve the effects of accelerating cooling shaping speed, ensuring quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

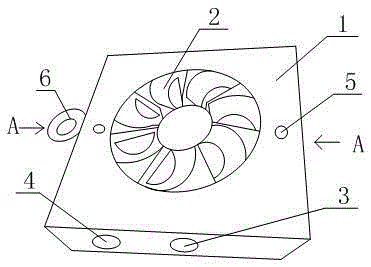

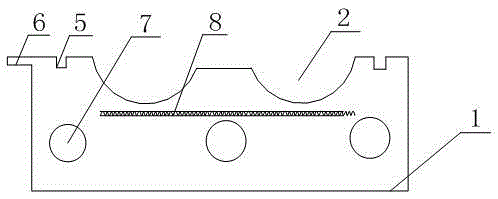

[0022] Such as figure 1 The fan blade forming mold shown includes a mold body 1 and a mold male body matched with the mold body 1. The fan blade injection groove 2 is arranged on the mold body 1, and the mold body 1 is located in the fan body. A cold water circulation pipe 7 is arranged below the blade injection groove 2, and the cold water circulation pipe 7 is located at the bottom of the fan blade injection groove 2, and a heating module 8 is arranged in the mold matrix 1, and the mold matrix 1 is fixed With pull ring6.

[0023] The mold matrix 1 is provided with a water outlet 3 and a water inlet 4, and the cold water circulation pipe 7 is connected to the water outlet 3 and the water inlet 4 respectively.

[0024] The water inlet 4 is provided with a water velocity control switch.

[0025] The mold body 1 is provided with a mold body fixing hole 5 .

[0026] The heating module 8 is located between the cold water circulation pipe 7 and the fan blade injection groove 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com