High-compaction and high-energy-density ultrahigh-nickel ternary positive electrode material

A high energy density, cathode material technology, applied in the field of ultra-high nickel ternary cathode materials, can solve the problems of unexplored material properties, difficult to achieve large-scale mass production, unexplored polycrystalline and single crystal, etc., to achieve DCR The effect of good growth performance, simplified production process, improved cycle and DCR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

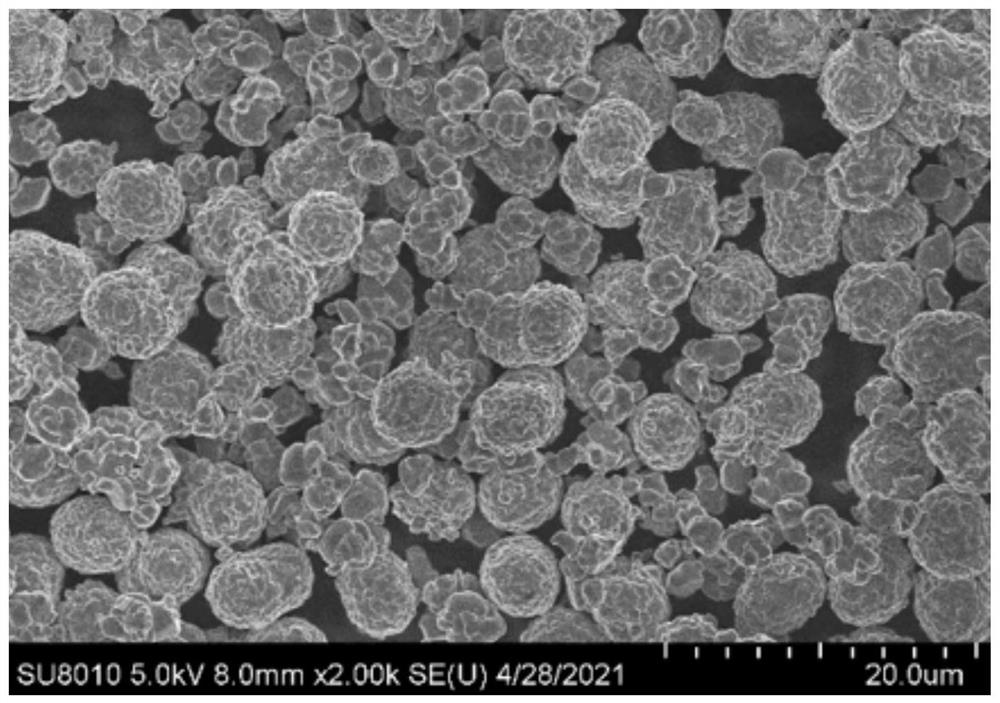

Embodiment 1

[0057] The preparation method of the ultra-high nickel ternary cathode material of high compaction and high energy density described in embodiment 1 comprises the following steps:

[0058] Preparation of polycrystalline materials:

[0059] S1: Ni with D50 of 6 μm 0.96 co 0.03 mn 0.01 (OH) 2 Precursor particles, with LiOH*H 2 O, 2500ppm additive ZrO 2 Mixing in a high mixer, the molar ratio of the lithium source to the sum of metal Ni, Co and Mn ions is 1.06 to obtain the first mixture;

[0060] S2: the above-mentioned first mixture is sintered for 12 hours at a temperature of 715°C by introducing oxygen into an oxygen atmosphere box furnace to obtain a first sintered product;

[0061] S3: The above-mentioned first sintered product is crushed by mechanical grinding, and the water washing process is carried out in the aqueous solution, and LiOH*H is added to the aqueous solution 2 O, and filter and dry to obtain the dried product;

[0062] S4: mix the above drying produc...

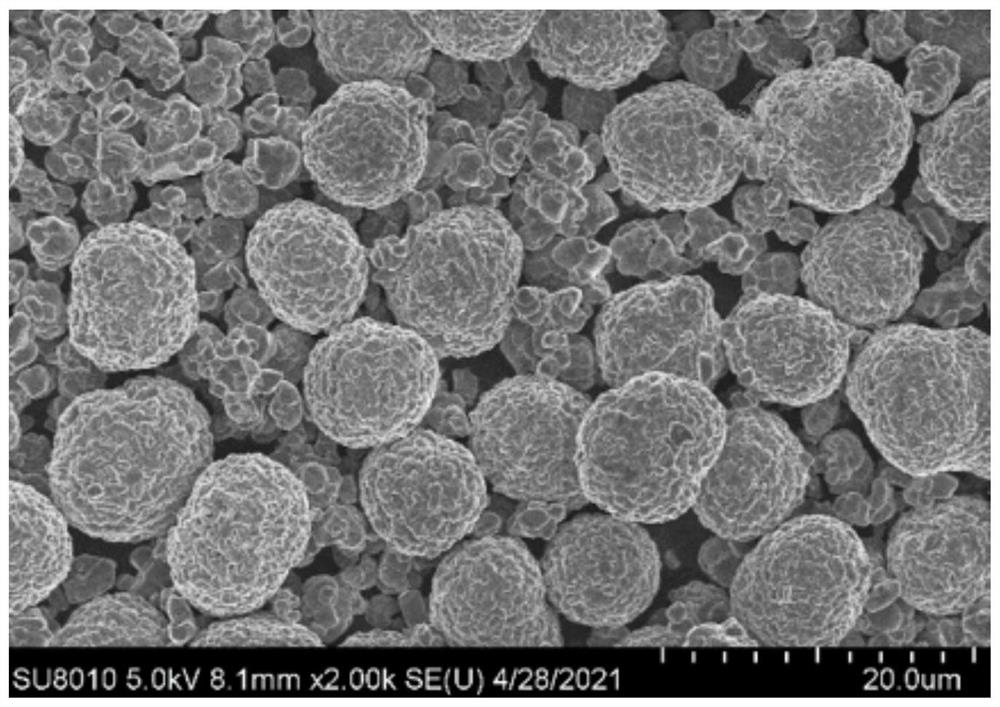

Embodiment 2

[0077] The preparation method of the ultra-high nickel ternary cathode material of high compaction and high energy density described in embodiment 2 comprises the following steps:

[0078] S1: Ni with D50 of 9 μm 0.96 co 0.03 mn 0.01 (OH) 2 Precursor particles, with LiOH*H 2O, 2500ppm additive ZrO 2 Carry out mixing in a high mixer, the molar ratio of the lithium source to the sum of metal Ni, Co and Mn ions is 1.06, and the first mixture is obtained;

[0079] S2: the above-mentioned first mixture is sintered for 12 hours at a temperature of 725° C. by feeding oxygen into an atmosphere box furnace to obtain a first sintered product;

[0080] S3: The above-mentioned first sintered product is crushed by mechanical grinding, and the water washing process is carried out in the aqueous solution, and LiOH*H is added to the aqueous solution 2 O, and filter and dry to obtain the dried product;

[0081] S4: mix the above drying product with 1500ppmH 3 BO 3 mixing to obtain a s...

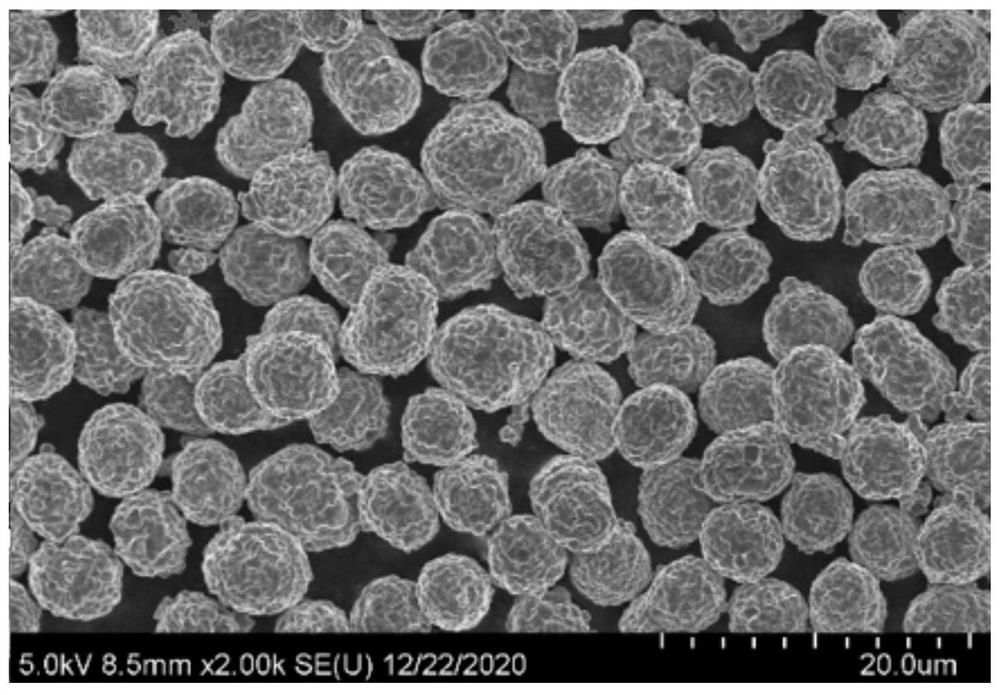

Embodiment 3

[0091] The preparation method of the ultra-high nickel ternary cathode material of high compaction and high energy density described in embodiment 3 comprises the following steps:

[0092] S1: Ni with D50 of 3 μm 0.96 co 0.03 mn 0.01 (OH) 2 Precursor particles, with LiOH*H 2 O, 2500ppm additive ZrO 2 Carry out mixing in a high mixer, the molar ratio of the lithium source to the sum of metal Ni, Co and Mn ions is 1.06, and the first mixture is obtained;

[0093] S2: Sintering the first mixture above for 12 hours at a temperature of 735° C. by feeding oxygen into an atmosphere box furnace to obtain a first sintered product;

[0094] S3: The above-mentioned first sintered product is crushed by mechanical grinding, and the water washing process is carried out in the aqueous solution, and LiOH*H is added to the aqueous solution 2 O, and filter and dry to obtain the dried product;

[0095] S4: mix the above drying product with 1500ppmH 3 BO 3 mixing to obtain a second mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com